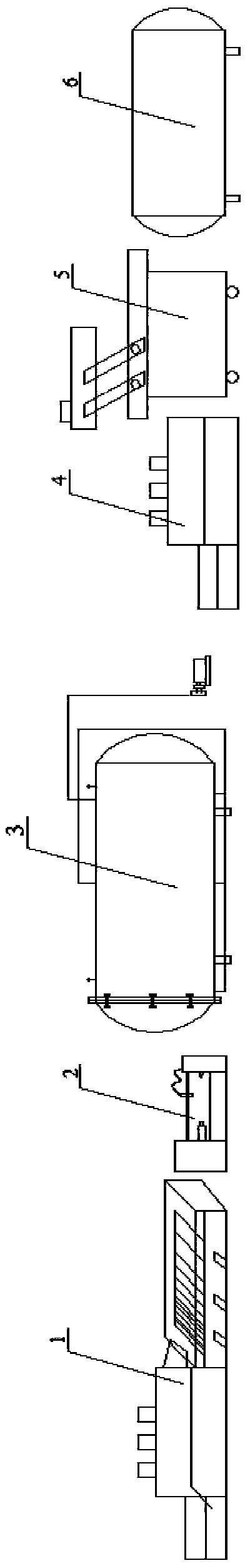

Pickling method for fast pickling salted duck eggs in laser etching assistance way and implementation system thereof

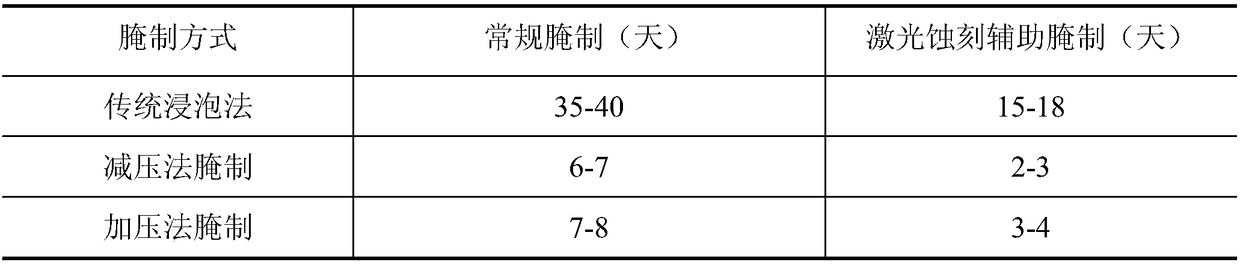

A technology of laser etching and salted duck eggs, applied in food science, food preservation, application, etc., can solve the problems of accelerating the permeation rate of sodium chloride solution, increasing the permeation area of sodium chloride solution, shortening the salted egg salting time, etc., to achieve The effect of increasing the oil yield of egg yolk, shortening the curing time and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of rapid pickling method for salted duck eggs assisted by traditional soaking method by laser etching, the specific steps are as follows:

[0040] (1) Cleaning and grading of fresh eggs: wash the duck eggs with clean water, check and remove runny eggs, cracked eggs, loose yolk eggs, and mildewed eggs, and grade the dried duck eggs according to their weight, and put them in with a volume fraction of Soak in 3% citric acid solution for 15 minutes, wash off the outer membrane of the eggshell and set aside;

[0041] (2) Preparation of saturated salt water: sterilize the drinking water with an ultraviolet sterilizer, add the calculated sodium chloride, stir continuously until the sodium chloride dissolves to obtain a saturated solution, filter, remove impurities, and cool for subsequent use;

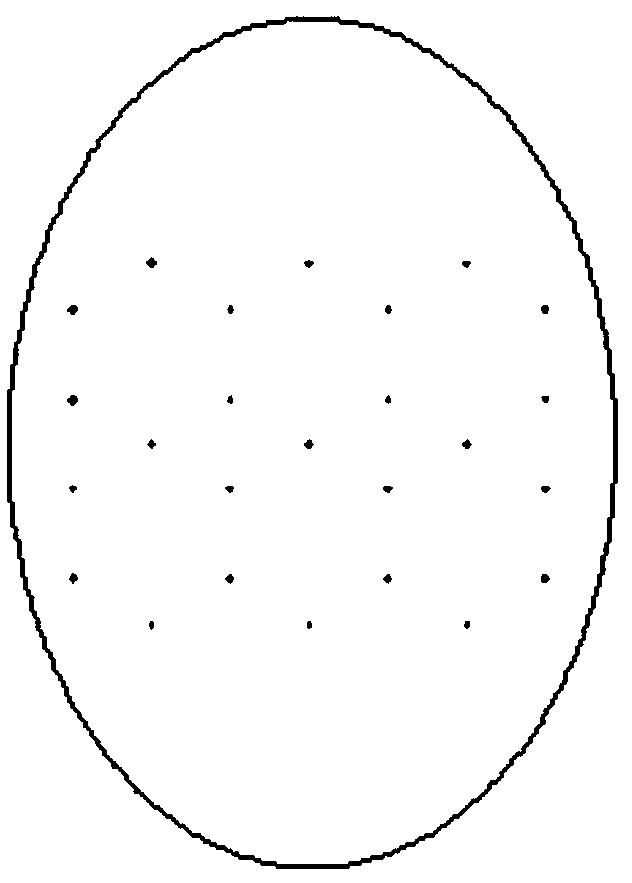

[0042](3) Laser engraving of fresh eggs: code the duck eggs processed in step (1) into the conveyor belt, and send them to the laser engraving machine for eggshell pretreatment....

Embodiment 2

[0048] A kind of rapid pickling method of salted duck eggs assisted by vacuum decompression method by laser etching, the specific steps are as follows:

[0049] (1) Wash the duck eggs with clean water, check and remove the runny eggs, cracked eggs, loose yolk eggs, and moldy eggs, grade the dried duck eggs according to their weight, and put them into a citric acid solution with a volume fraction of 5%. Soak for 10 minutes, wash off the dirt and eggshell membrane outside the eggshell and set aside;

[0050] (2) Preparation of saturated salt water: sterilize drinking water with an ultraviolet sterilizer, add calculated sodium chloride, constantly stir to obtain saturated salt water, filter, remove impurities, and cool for subsequent use;

[0051] (3) Laser etching of fresh eggs: code the duck eggs processed in step (1) into the conveyor belt, and send them to the laser engraving machine for eggshell pretreatment. Use the egg tray of the laser etching machine to fix one end of t...

Embodiment 3

[0057] A kind of rapid pickling method for salted duck eggs with laser etching assisted pressurization method, the specific steps are as follows:

[0058] (1) Cleaning and grading of fresh eggs: wash the duck eggs with clean water, check and remove runny eggs, cracked eggs, loose yolk eggs, and mildewed eggs, and grade the dried duck eggs according to their weight, and put them in with a volume fraction of Soak in 2% citric acid solution for 15 minutes, wash off the outer membrane of the eggshell and set aside;

[0059] (2) Preparation of saturated salt water: sterilize drinking water with an ultraviolet sterilizer, add calculated sodium chloride, constantly stir to obtain saturated salt water, filter, remove impurities, and cool for subsequent use;

[0060] (3) Laser etching of fresh eggs: code the duck eggs processed in step (1) into the conveyor belt, and send them to the laser engraving machine for eggshell pretreatment. Use the egg tray of the laser etching machine to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com