Method for pickling pawpaw and pickled pawpaw product

A technology of papaya and products, which is applied in the field of pickled papaya and prepared papaya pickled products, can solve the problems of low degree of mechanization, poor safety, long cycle, etc., achieve high safety, improve production efficiency, and short pickling cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

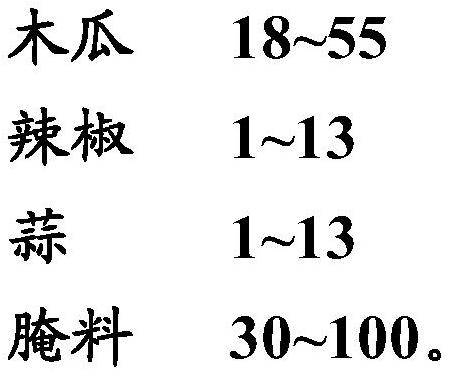

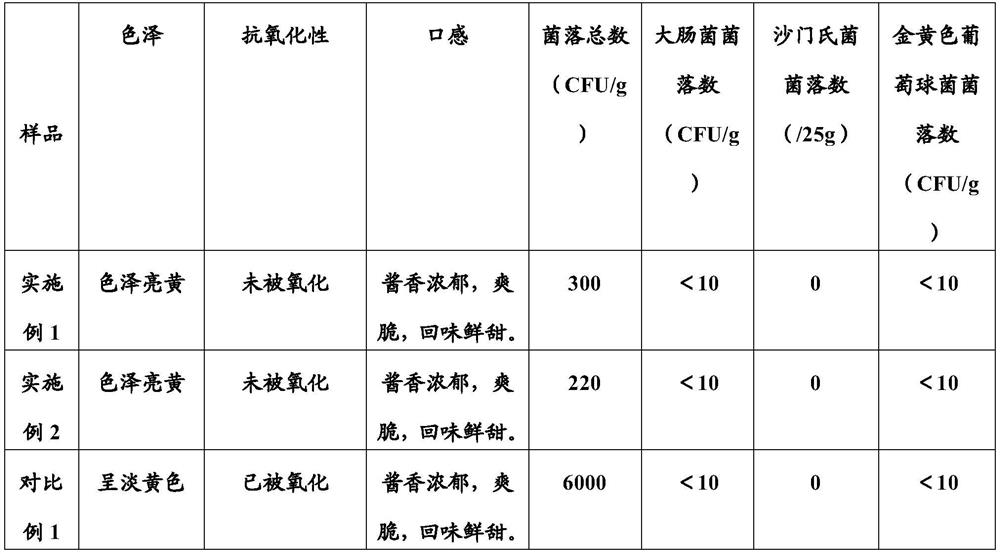

Embodiment 1

[0042] (1) Fresh papaya is cleaned, peeled and shredded, dried, selected to remove impurities, then evenly spread on the shelf, and subjected to ozone sterilization treatment to obtain sterilized dried papaya shreds for subsequent use;

[0043] (2) remove the stems of fresh peppers and screen out moldy or rotten peppers and sundries, clean the screened peppers and garlic, and sterilize them with boiling water and crush them to 5-10mm for later use;

[0044] (3) In parts by weight, take 50 parts of rock sugar or white granulated sugar, 0.2 parts of potassium sorbate (preservative), and 0.2 parts of D-sodium erythorbate (antioxidant) and dissolve them completely in hot water in a clean container, and then add 30 parts of super soy sauce (amino acid nitrogen content ≥ 1.2g / 100mL), 13 parts of brewed vinegar, 3 parts of cooking wine, add water to a total of 100 parts by weight, and completely mix to obtain a feed liquid;

[0045] (4) According to parts by weight, take 500 parts of...

Embodiment 2

[0049] (1) Fresh papaya is cleaned, peeled and shredded, dried, selected to remove impurities, then evenly spread on the shelf, and subjected to ozone sterilization treatment to obtain sterilized dried papaya shreds for subsequent use;

[0050] (2) remove the stems of fresh peppers and screen out moldy or rotten peppers and sundries, clean the screened peppers and garlic, and sterilize them with boiling water and crush them to 5-10mm for later use;

[0051] (3) According to parts by weight, take 50 parts of rock sugar or white granulated sugar, 0.2 parts of potassium sorbate (preservative), and 0.2 parts of D-sodium erythorbate (antioxidant), dissolve them completely in hot water in a clean container, and then add 30 parts of super soy sauce (amino acid nitrogen content ≥ 1.2g / 100mL), 13 parts of brewed vinegar, 3 parts of cooking wine, add water to a total of 100 parts by weight, and completely mix to obtain a feed liquid;

[0052] (4) According to parts by weight, take 700 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com