Double-layer splitter plate hot runner

A splitter plate and hot runner technology, which is applied in the field of improvement of splitter plates in hot runner injection molds, can solve the problems of difficulty in balancing the flow of plastic materials, difficulty in processing large splitter plates, and high processing costs of hot runners, and achieve favorable flow balance , simple processing, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

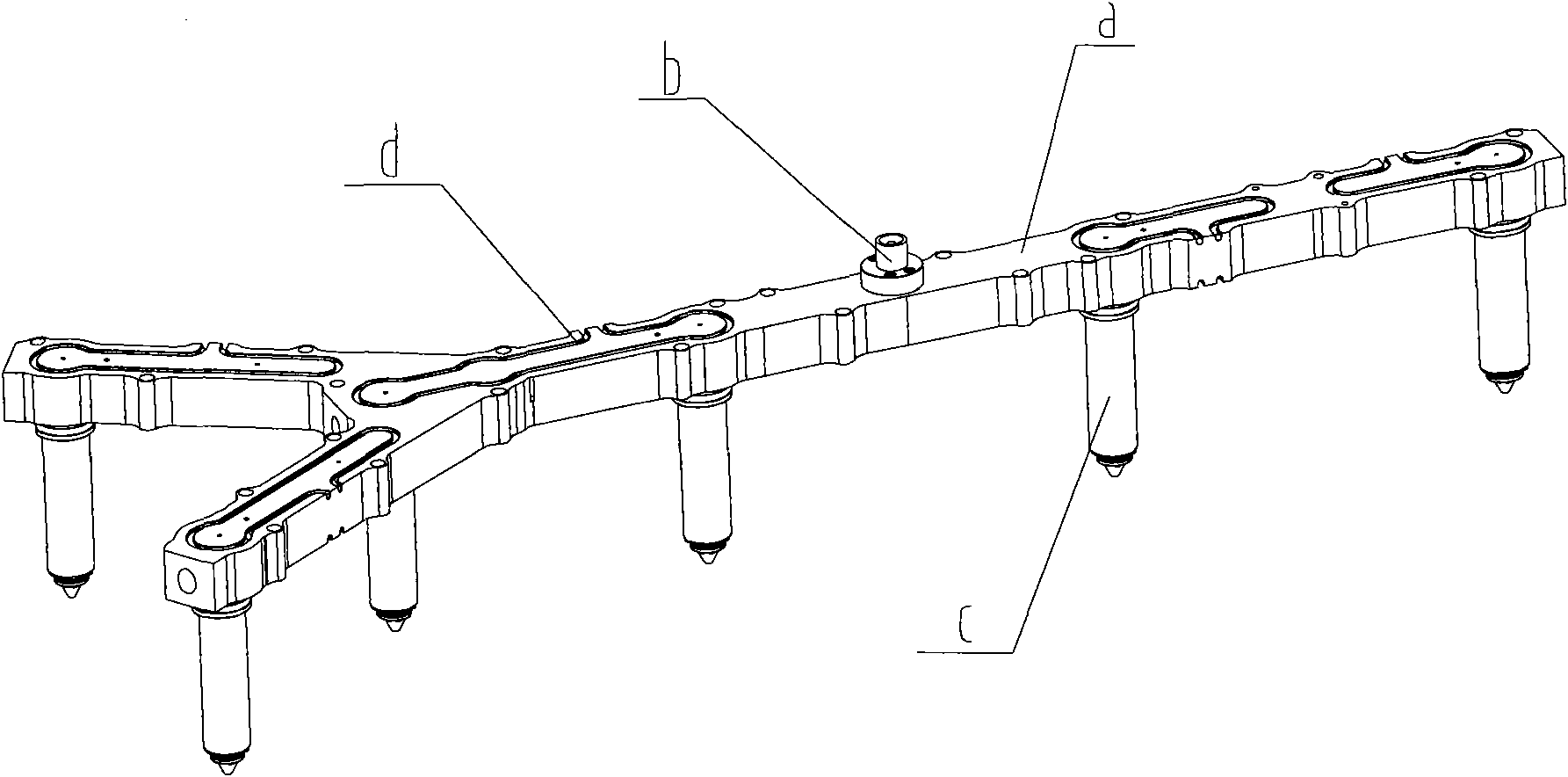

[0027] figure 1 Shown is the single-layer manifold hot runner mentioned in the previous background technology, including manifold a, main nozzle b, hot nozzle body c, and heating wire d. During the injection molding process, the heating wire d is heated to divert flow when forming large plastic products The length of the plate a is very large, so its thermal expansion is very large, which may easily cause the valve needle in the nozzle body c to be stuck at the nozzle. At the same time, due to the limitation of the processing technology, it is difficult to ensure the distribution of the nozzle body c The distance to each hot nozzle body c is equal, so the flow of molten material in the cavity is unbalanced, which affects the quality of the product; moreover, the processing of this complex manifold is difficult and requires large-scale equipment.

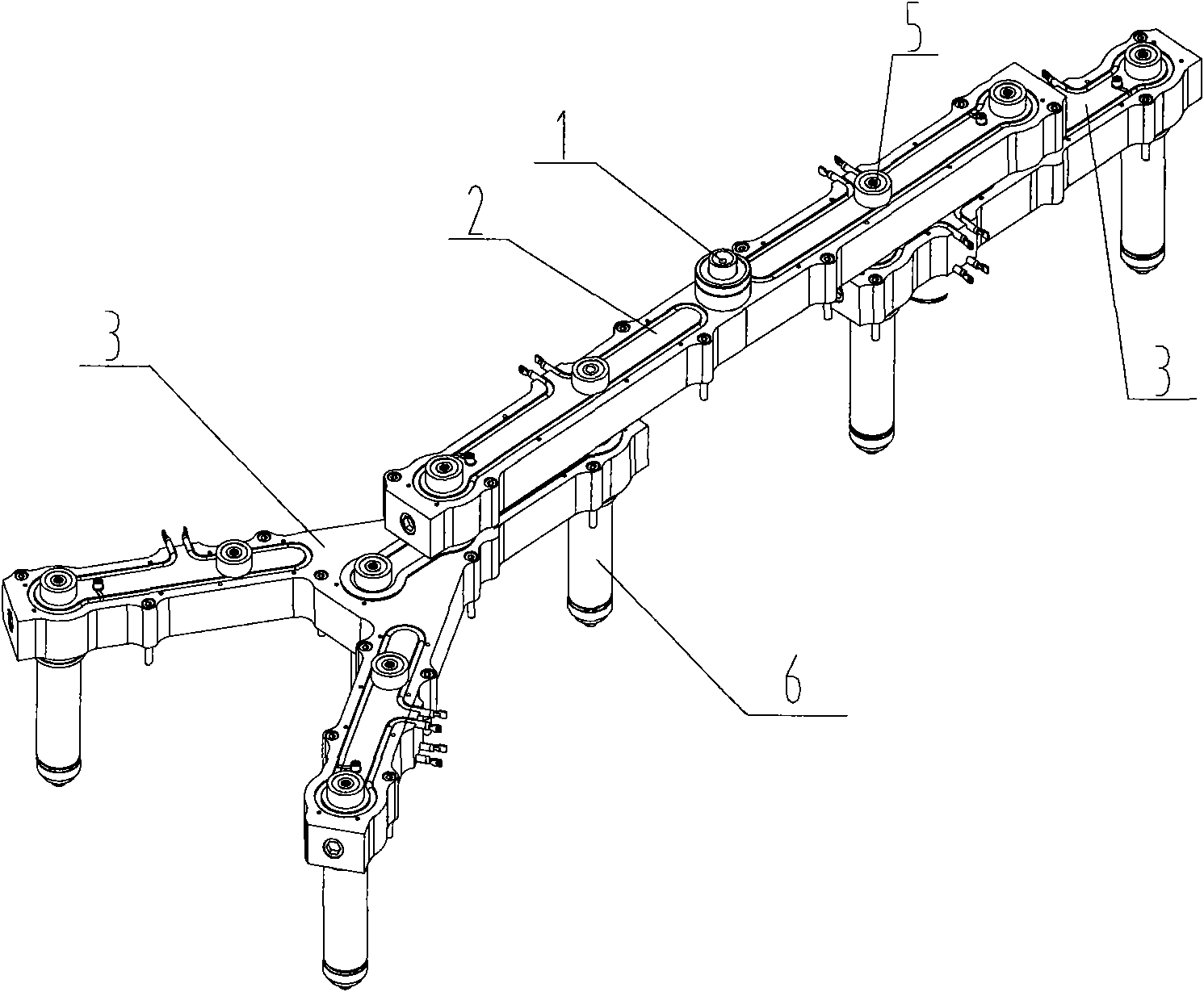

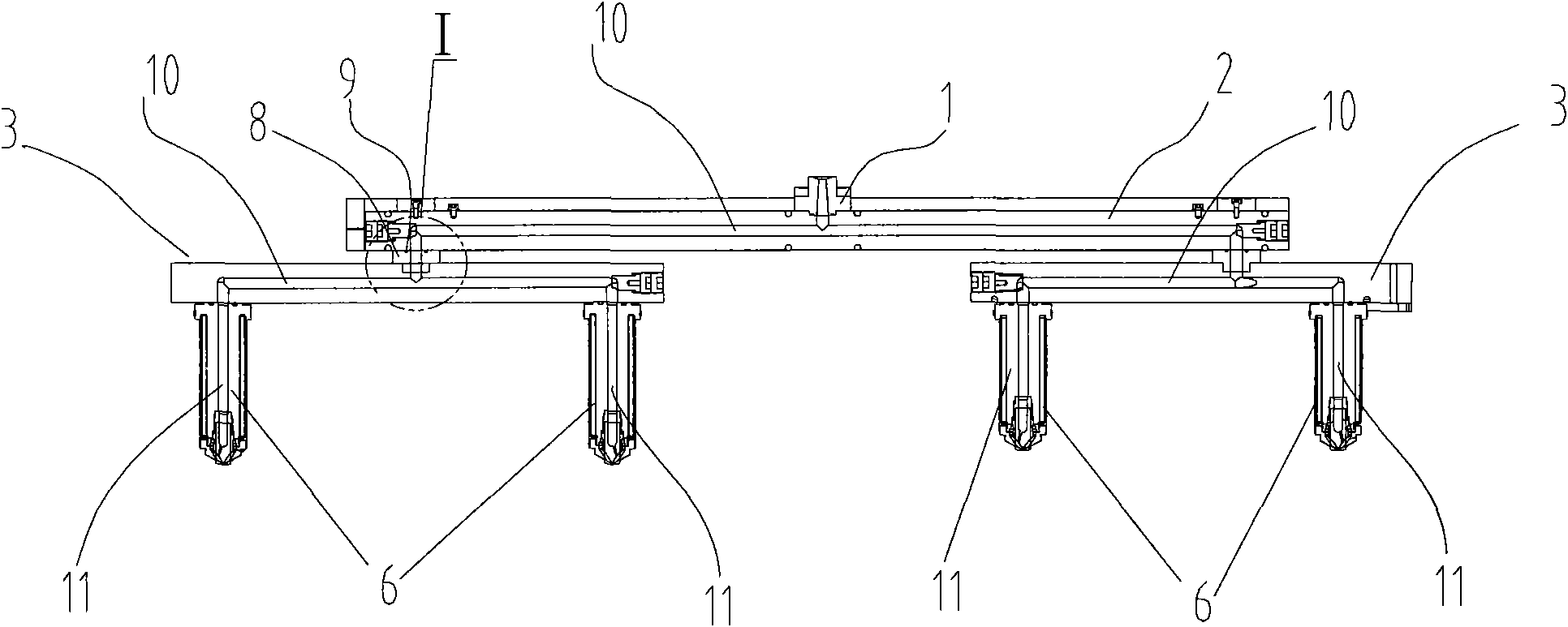

[0028] see Figure 2 to Figure 5 , the double-layer manifold hot runner of the present invention used for forming the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com