Continuous rolling clamping device for flexible substrate

A technology of soft base material and clamping device, which is applied in the direction of lamination device, lamination, control lamination, etc. It can solve the problems of unintegrated alignment, low pressure and position accuracy, and inability to roll pressure immediately in lamination manufacturing process. Feedback and other issues to achieve the effect of overcoming the problem of uneven product thickness, solving the demand for manufacturing process precision, and precise bonding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

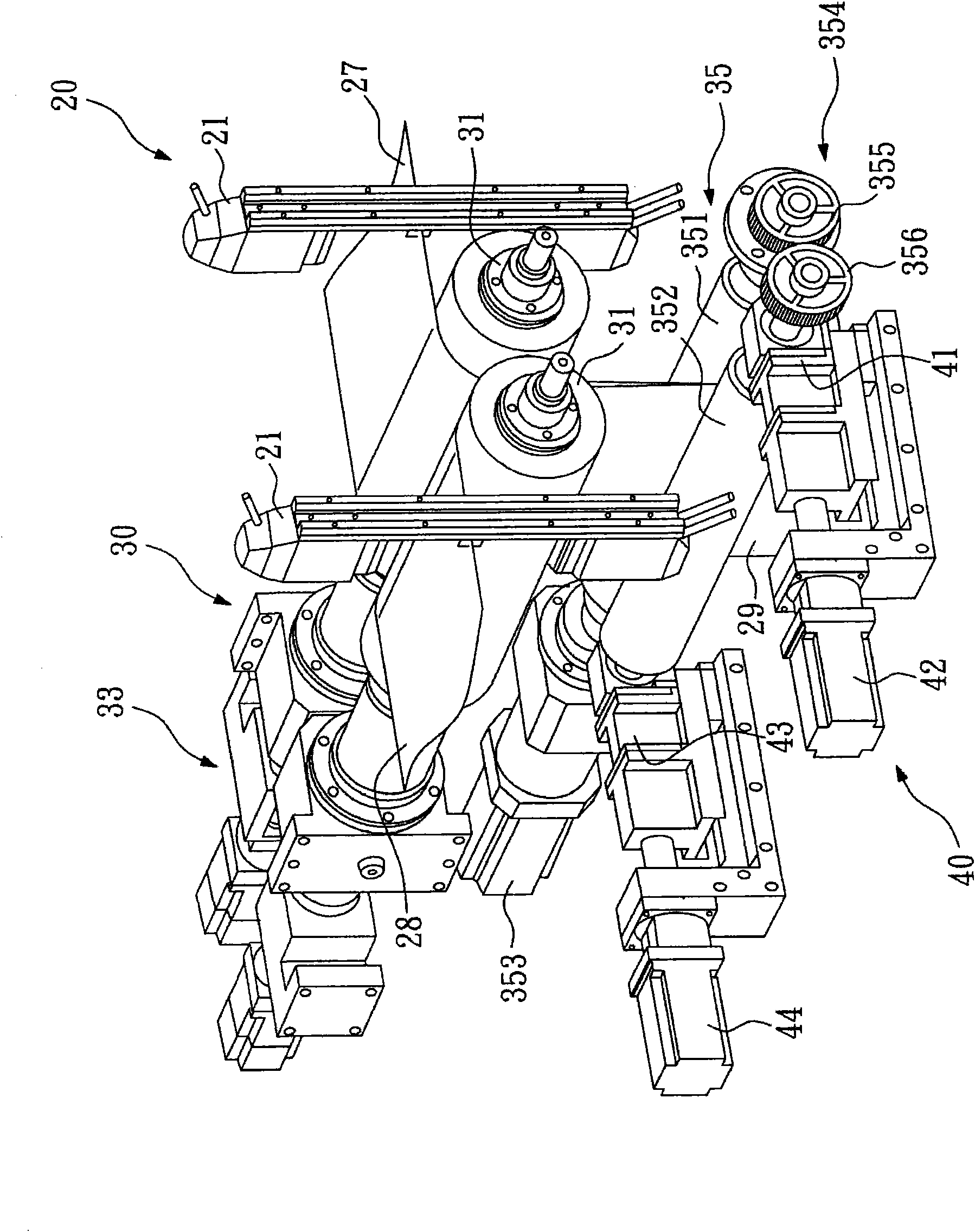

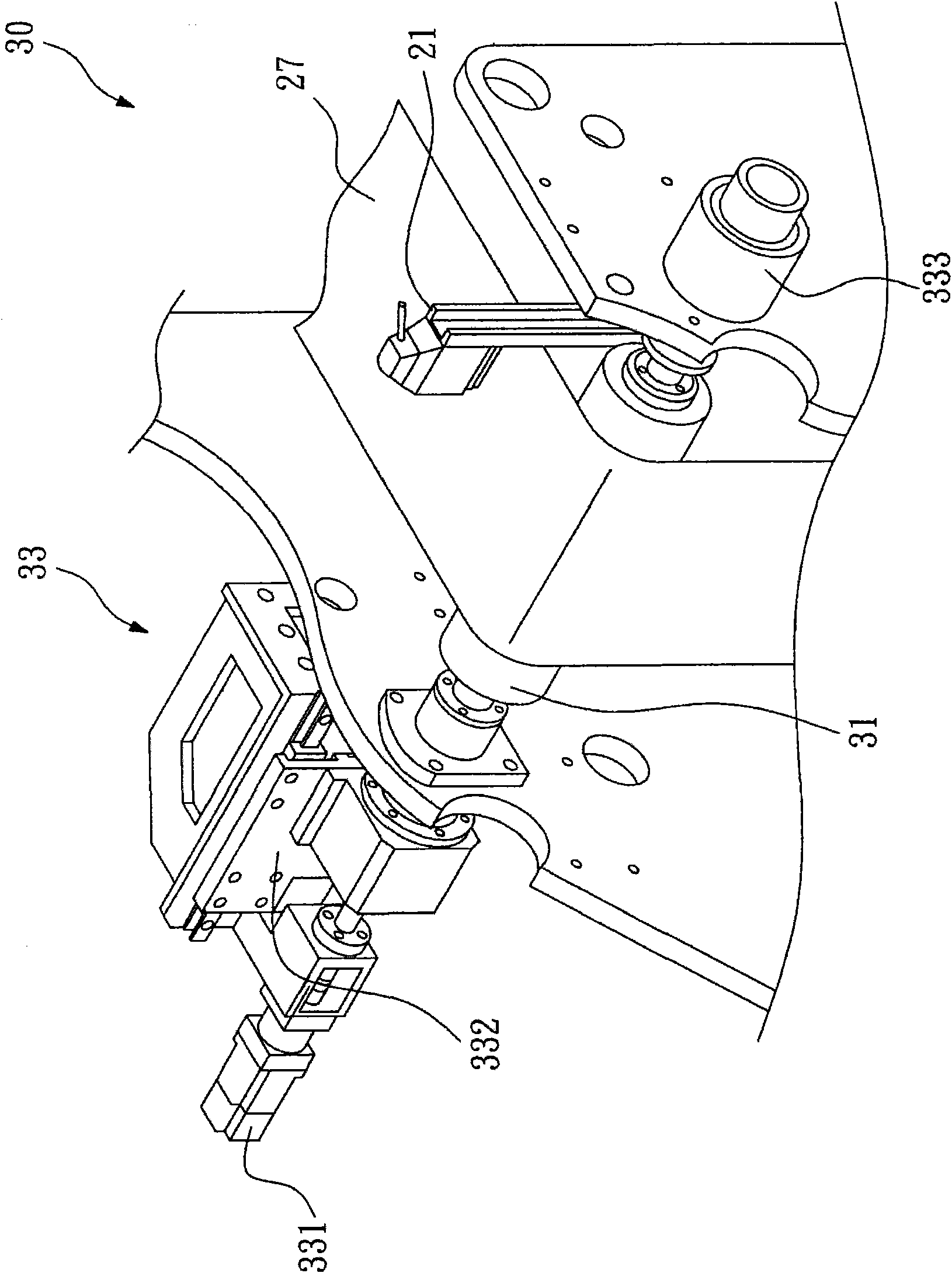

[0056] reference figure 2 , Which shows a schematic diagram of a continuous rolling clamping device for flexible substrates according to the first embodiment of the present invention. The first embodiment of the present invention is a continuous rolling type clamping device 20 for a flexible substrate comprising: at least one reference position sensing device 21, at least one flexible substrate positioning device 30, and at least one clamping roller set 35 And at least one clamping force applying device 40. At least one reference position sensing device is used for sensing a set position of at least one flexible substrate to generate at least one position sensing value. In this embodiment, there are two reference position sensing devices 21 for respectively sensing a set position of the two flexible substrates 27 and 28 to generate at least one position sensing value. The set position of the flexible substrate is at least one reference mark on the side of the flexible substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com