Gyroscopic control system for tyre crane

A technology of tire crane and control system, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of unstable operation of the slewing controller, complex control system, unsatisfactory effect, etc., to reduce the hidden danger of power supply, High control precision and the effect of increasing safety and stability

Inactive Publication Date: 2011-06-29

WUHAN UNIV OF TECH

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

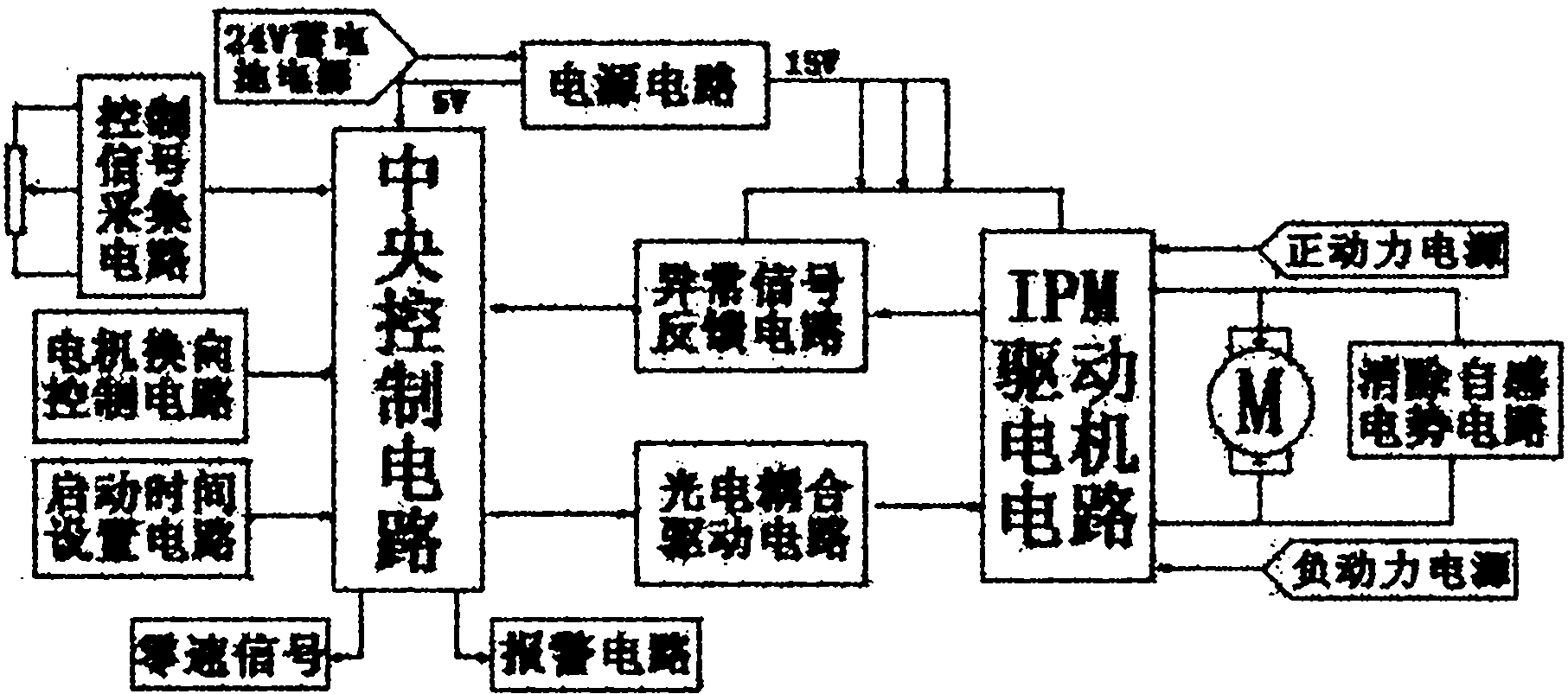

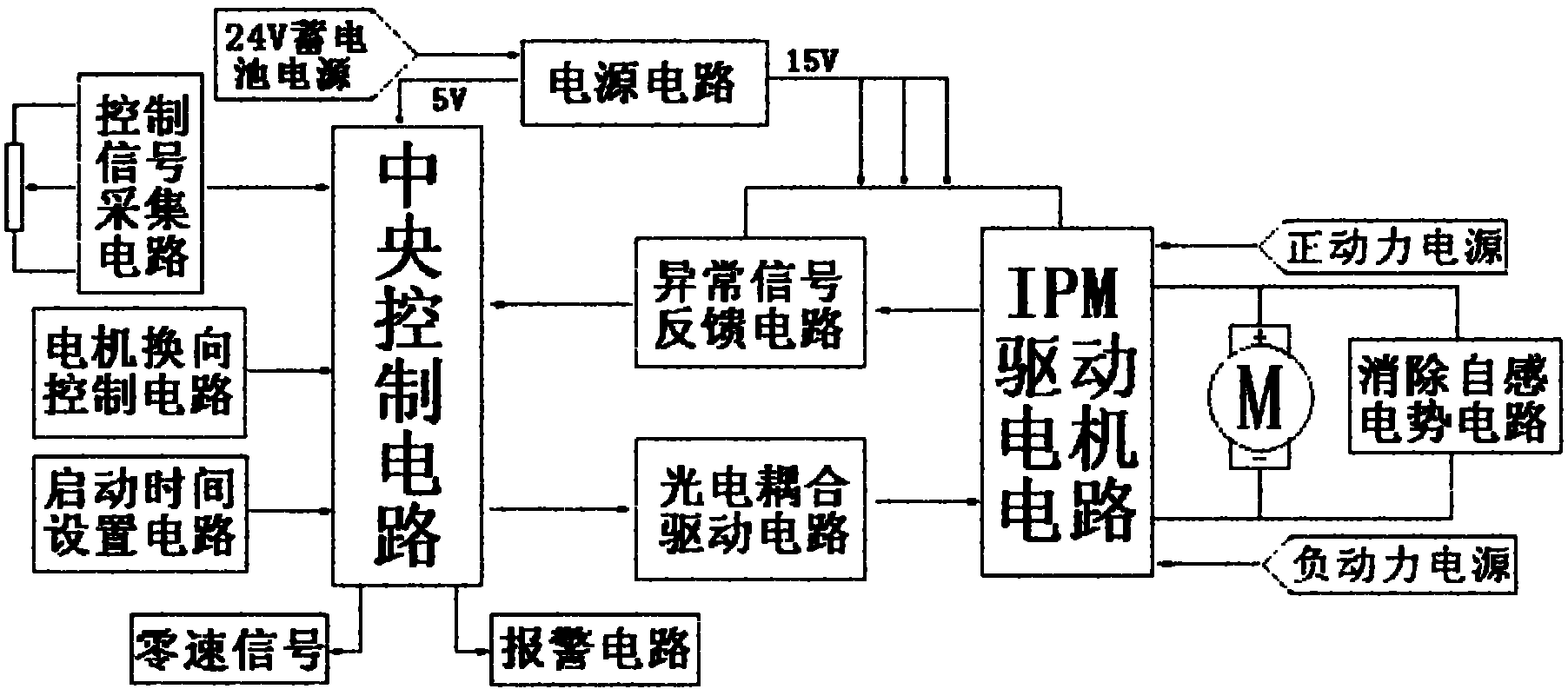

The invention relates to a gyroscopic control system for a tyre crane. The system is provided with a control circuit which is formed by a power supply circuit, a control signal collection circuit, a motor commutation control circuit, a start time setting circuit, a central control circuit, an optoelectronic coupling drive circuit, an intelligent power module (IPM) drive motor circuit, an abnormal signal feedback circuit, an alarm circuit and a self-induction potential elimination circuit, wherein the control signal collection circuit, the motor commutation control circuit, the start time setting circuit and the alarm circuit are connected with the central control circuit through leads respectively; the self-induction potential elimination circuit is connected with the IPM drive motor circuit; and the central control circuit and the IPM drive motor circuit are connected with each other through the optoelectronic coupling drive circuit and the abnormal signal feedback circuit. The gyroscopic control system has the advantages of strong practicality, simple and reasonable structure, small volume, lower cost, high safety and the like, can control the gyroscopic system to work quickly and smoothly and is beneficial to popularization and application.

Description

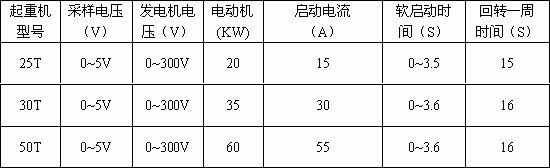

Wheel Crane Slewing Control System technical field The invention relates to the field of motor speed regulation control of a tire jib crane, in particular to a slewing control system of a tire crane. Background technique The tire jib crane is a common loading and unloading machine for port terminals and various construction projects. It can travel long distances, flexibly change the working site, and has good mobility. Its working characteristics are cyclic, repetitive, and intermittent operations, frequently lifting several tons to dozens of tons of goods, and moving the goods to the destination position through the operating mechanism, slewing mechanism or luffing mechanism. Due to the large load changes, especially the high timeliness of the port terminal, it is required that the tire crane can be started and braked in a short period of time, which requires that the slewing mechanism of the crane can run quickly and smoothly. At present, in the field of slewing control...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B66C13/22B66C23/84

Inventor 胡吉全唐静陈永兴

Owner WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com