Automatic cooling method and equipment in process of heating large forgings

A large-scale forging, automatic cooling technology, applied in the direction of heat treatment equipment, heat treatment furnace, furnace type, etc., can solve the problems of large temperature deviation, difficult to control the cooling process, etc., to achieve the effect of stable working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

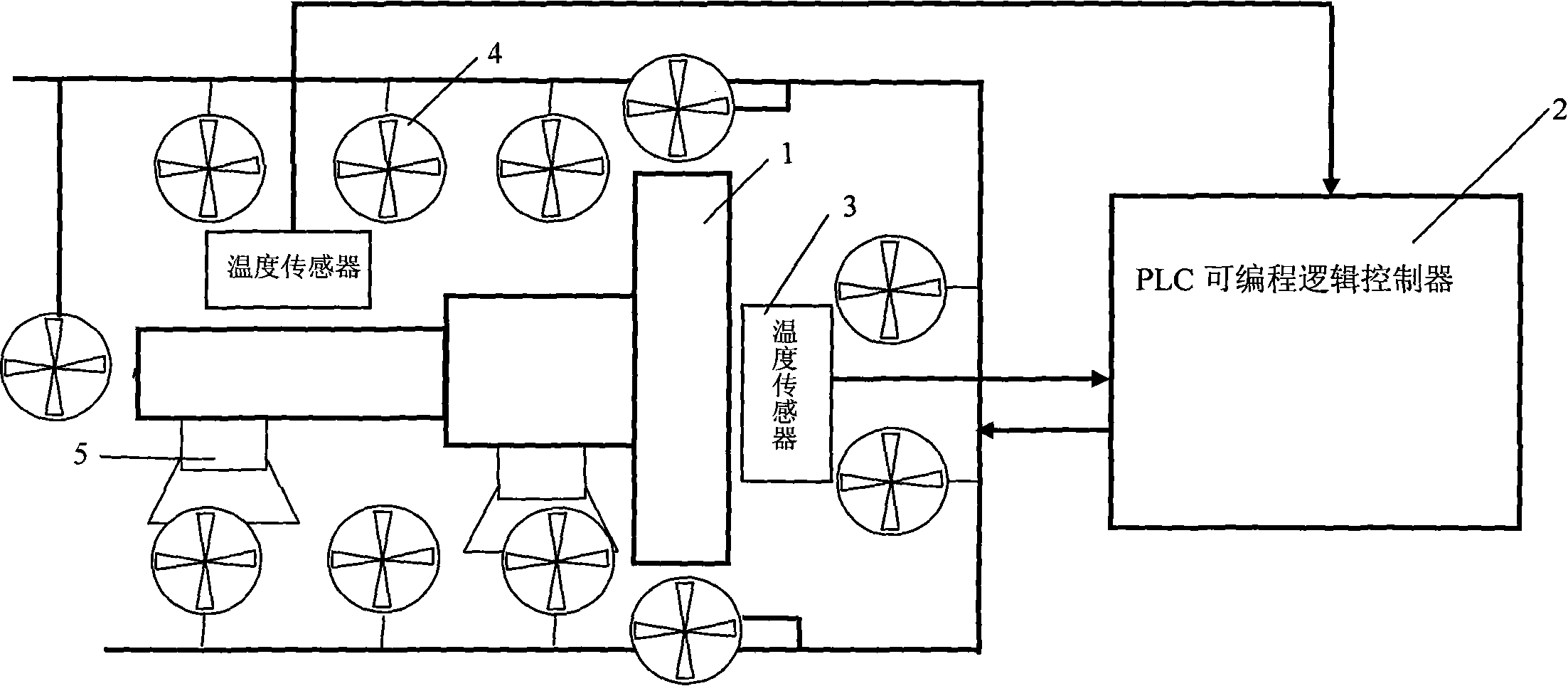

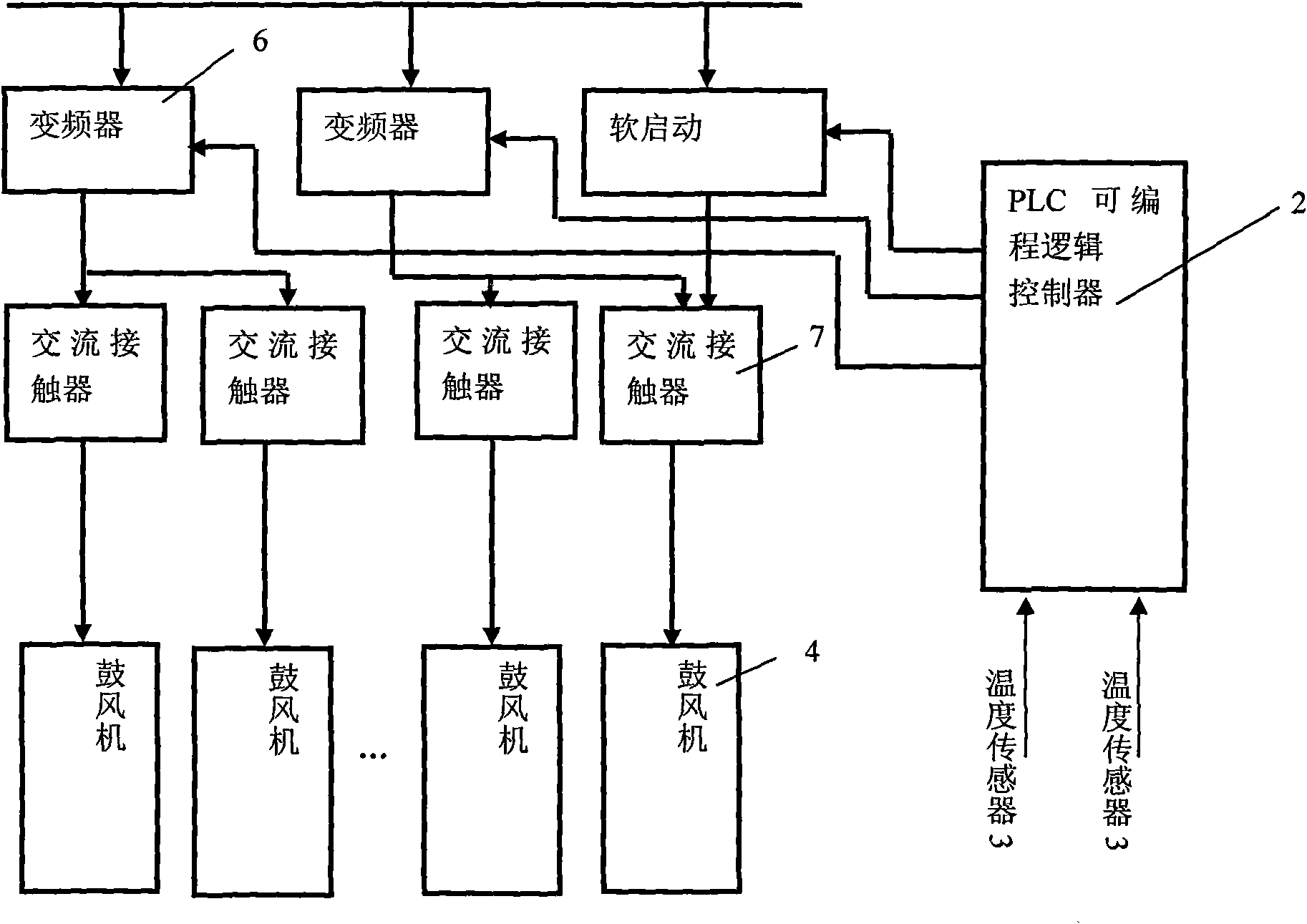

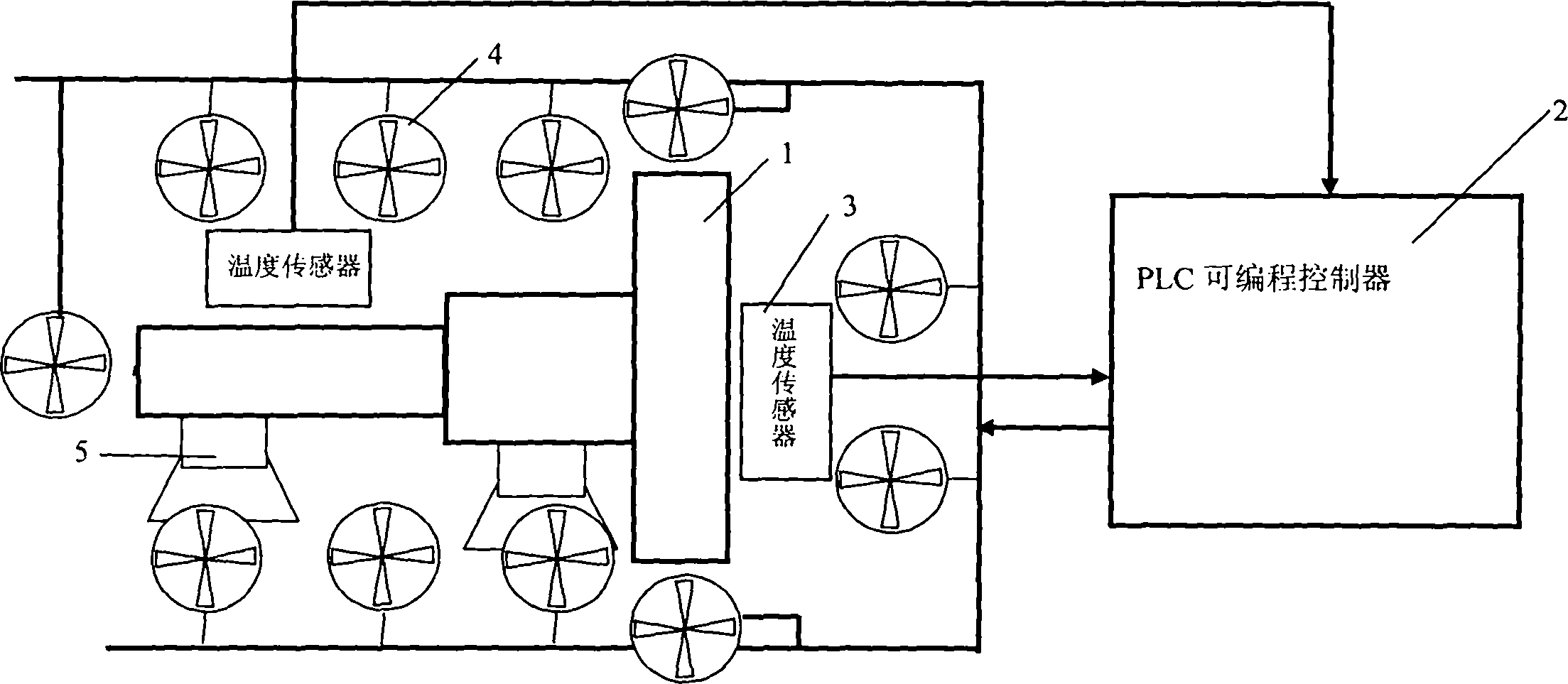

[0012] combine figure 1 The heating and automatic cooling equipment for large-scale forgings of the present invention includes large-scale forgings 1 that are cooled after heat treatment, a PLC speed regulation and control system, a number of temperature sensors 3, and a positioner 5. The PLC speed regulation and control system includes a PLC programmable logic controller 2. Frequency converter 6, AC contactor 7 and several blowers 4, frequency converter 6 is connected to PLC programmable logic controller 2, one end of AC contactor 7 is connected to blower 4, the other end is connected to frequency converter 6, temperature sensor 3 Pasted on the large forging 1, the temperature sensor 3 is connected to the PLC speed control and control system, the temperature signal of the temperature sensor 3 is input to the PLC programmable logic controller 2, and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com