Pressure-sharing cavity air thrust bearing

A thrust bearing and pressure cavity technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of limited accuracy, rareness, and complicated processing technology of porous materials for air-bearing bearings, so as to suppress the bearing vibration phenomenon, Hazard reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

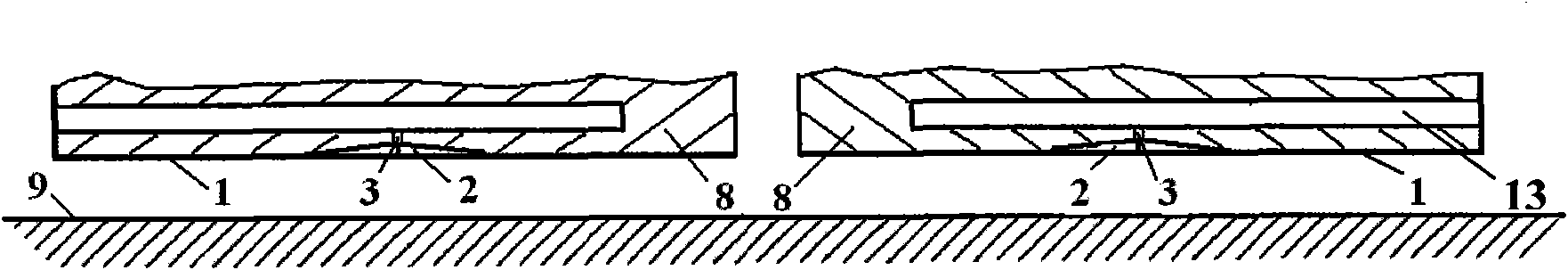

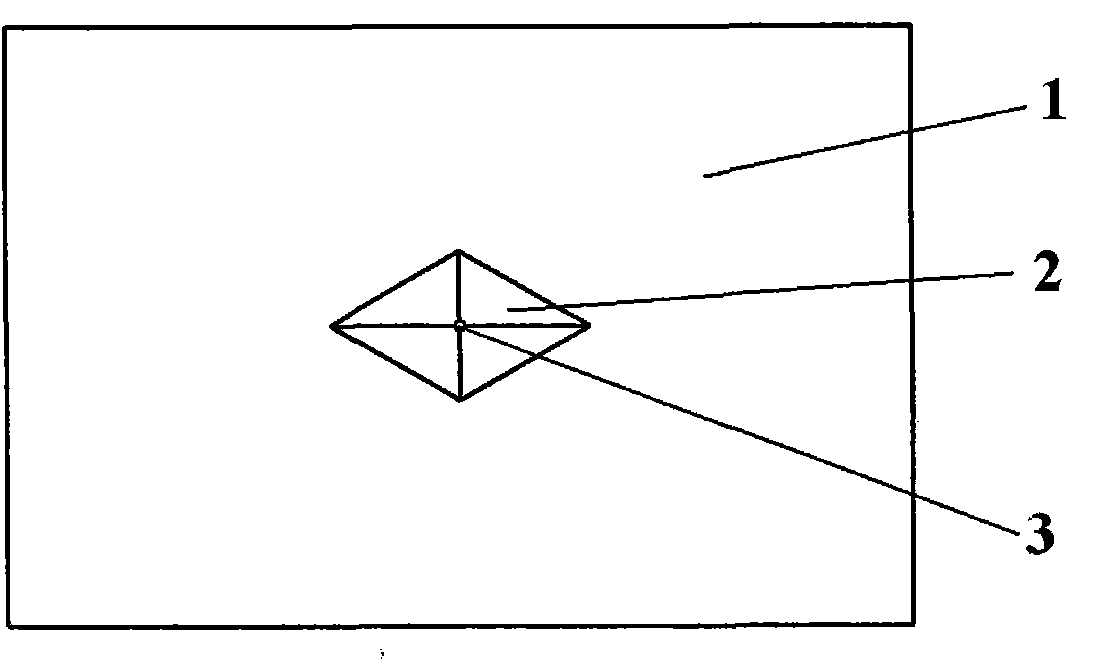

[0037] see figure 1 and figure 2 , figure 1 Shown is the sectional view of the air-floating thrust bearing in the equalizing chamber with two air-floating sliders in Embodiment 1; figure 2 Shown is a schematic diagram of the supporting surface of the air bearing slider with a single pressure equalization chamber in Example 1.

[0038] This pressure equalization chamber air bearing thrust bearing includes at least one air bearing slider 8 , and in this embodiment includes two air bearing sliders 8 . The support surface 1 of each air bearing slider is provided with at least one concave pyramid pressure equalization chamber 2, that is, the cross section of the pressure equalization chamber along the normal direction of the support surface 1 of the air bearing slider is pyramid-shaped. In this embodiment, each air bearing slider 8 is provided with a pyramid pressure equalization chamber 2 , and the pyramid pressure equalization chamber 2 is arranged at the center of the air b...

Embodiment 2

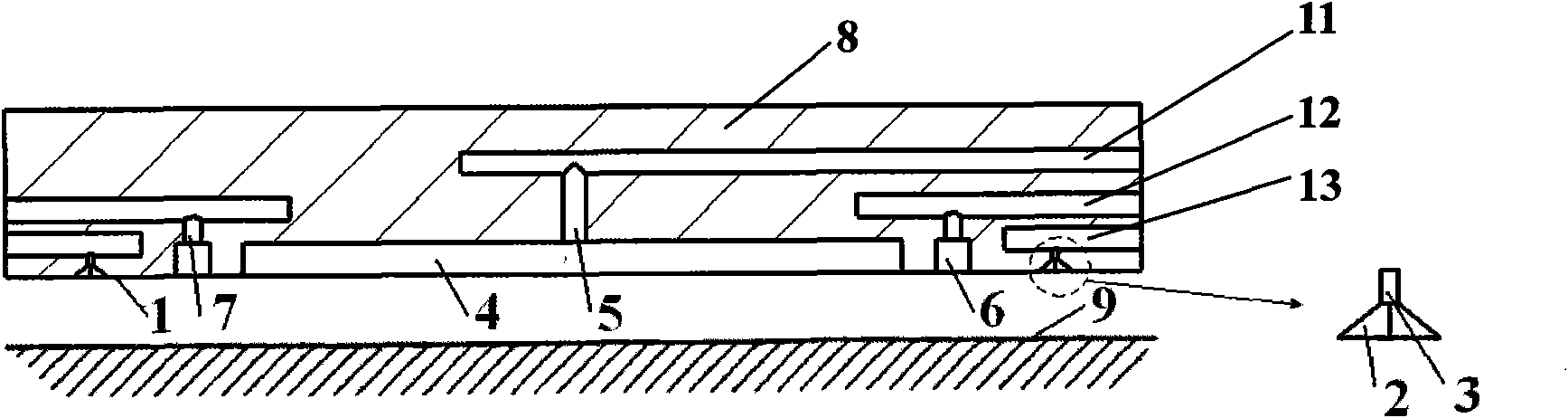

[0044] see image 3 and Figure 4 , image 3 Shown is the sectional view of the air-floating thrust bearing in the equalizing chamber with a single air-floating slider in Embodiment 2; Figure 4Shown is a schematic diagram of the supporting surface of the air bearing slider with four pressure equalization chambers in Example 2. This pressure equalization cavity air bearing thrust bearing includes an air bearing slider 8 and a base 9, and the air bearing slider 8 is circular. The support surface 1 of the air bearing slider is provided with four pyramidal pressure equalization chambers 2 along the circumferential direction, and an orifice 3 is respectively arranged at the apex of each pyramidal pressure equalization chamber 2 . The orifices 3 communicate with the air supply pipelines 13 inside the air bearing slider 8 respectively.

[0045] In addition, a circular vacuum chamber 4 is provided on the support surface 1 of the air bearing slider, and a vacuum hole 5 is opened i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com