Novel material transfer device

A technology for transferring devices and materials, applied to furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of poor carrying capacity of transfer devices, slow material transfer speed, large material friction and wear, etc., to achieve large carrying capacity and material transfer Fast, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

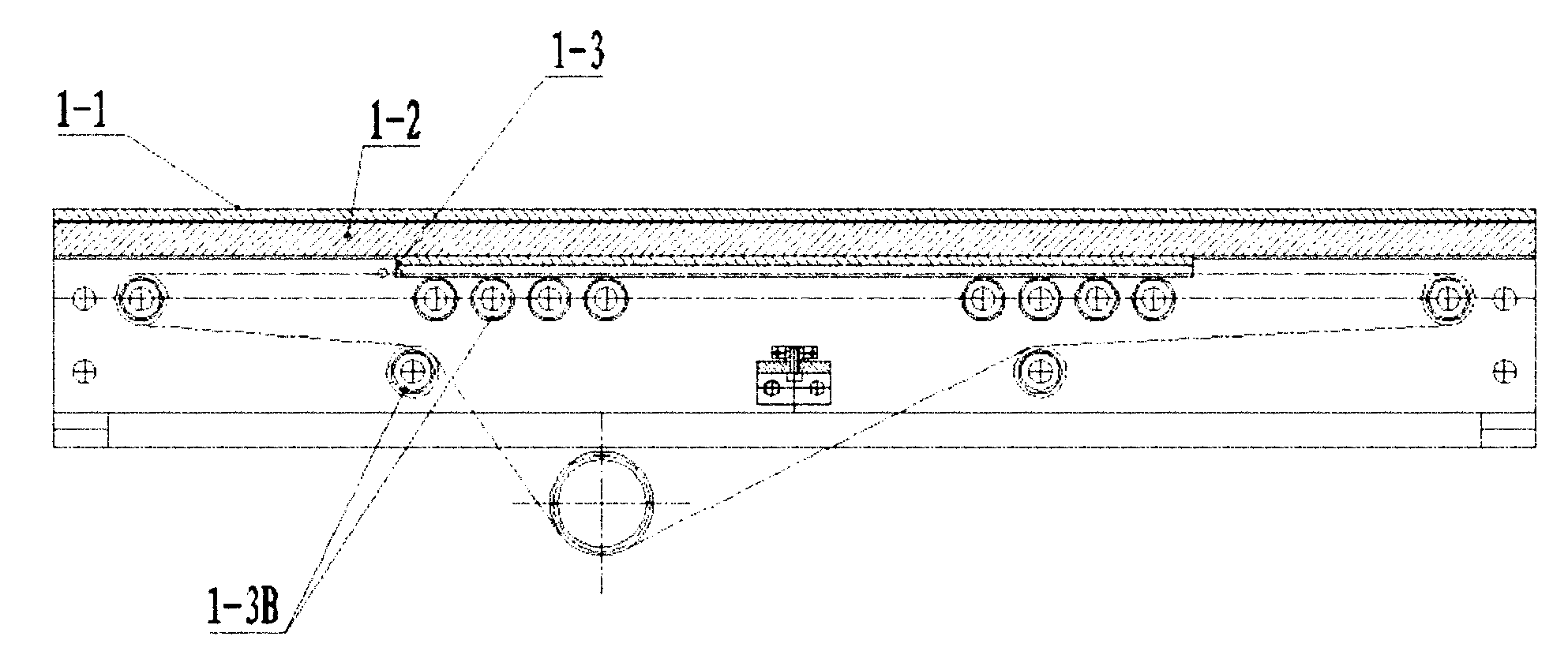

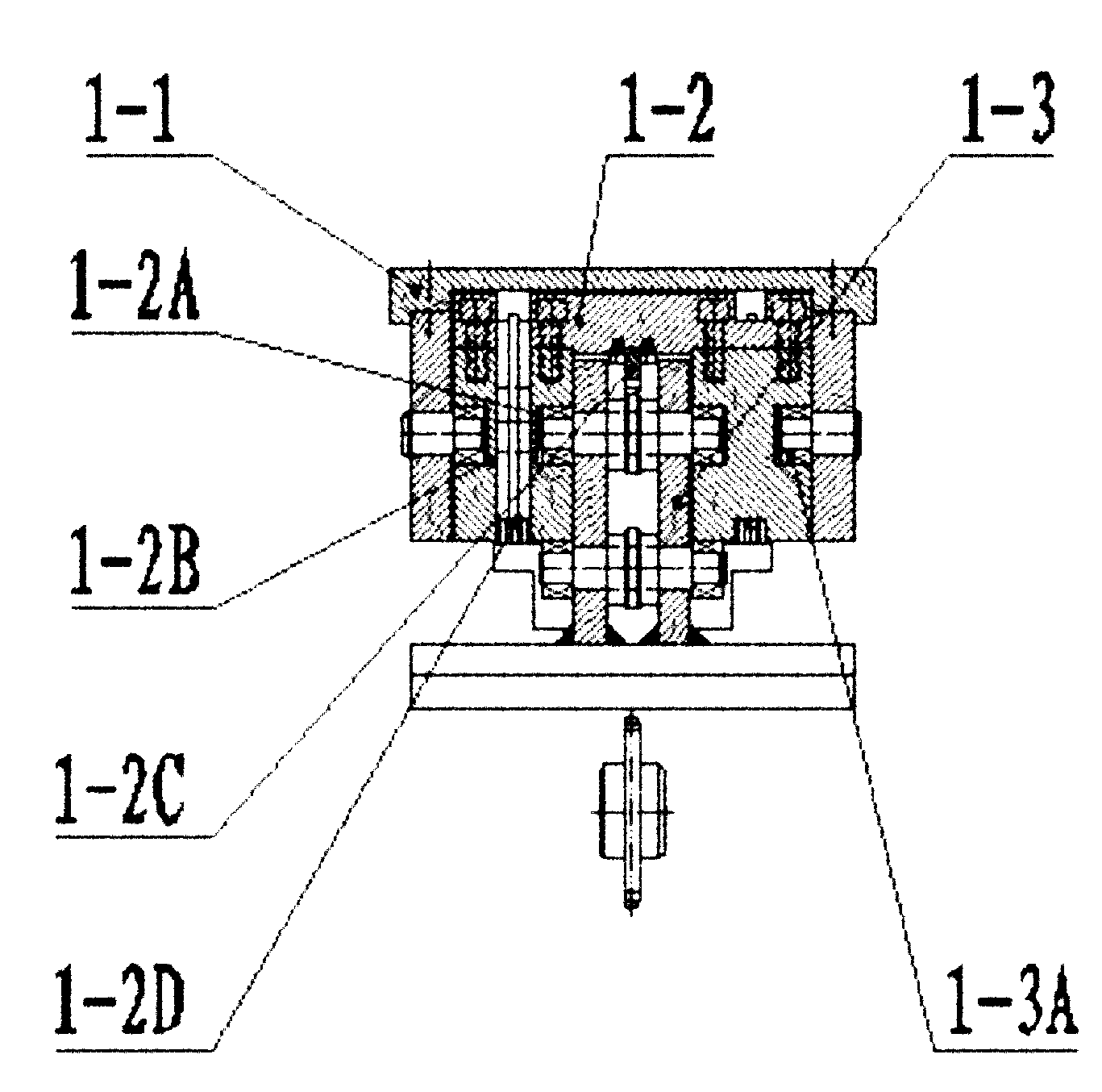

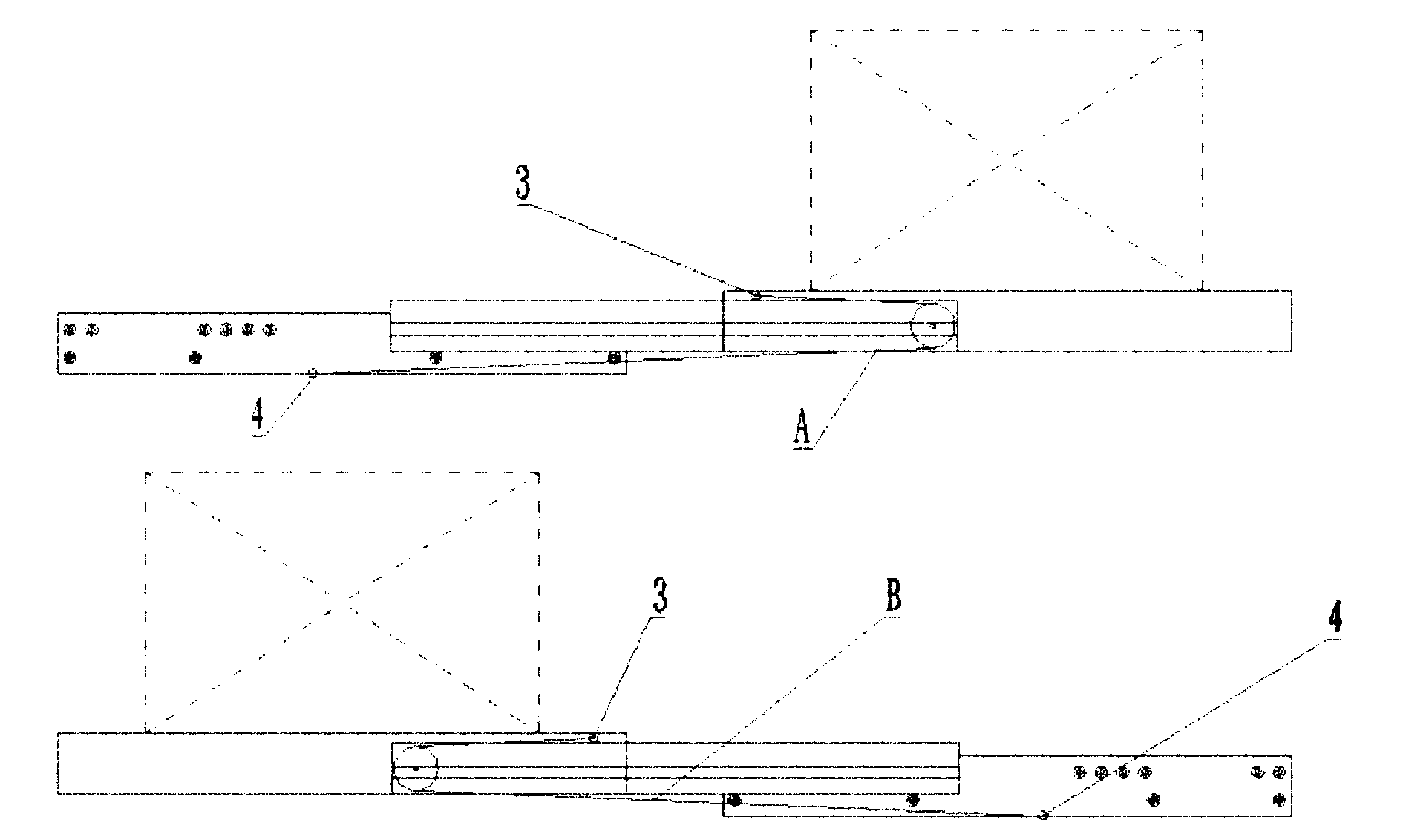

[0017] As shown in the figure, X-axis bidirectional drive mechanism 1: upper cantilever 1-1, lower cantilever 1-2, cantilever seat 1-3, lower cantilever drive mechanism 1-4, upper bevel gear set 1-5, transmission shaft 1-6, Lower bevel gear set 1-7; lower cantilever 1-2: inner roller guide 1-2A, outer roller guide 1-2B, sprocket rack 1-2C, left chain chute 1-2D, pulley system 1-3A, Chain pressure roller 1-3B; upper cantilever drive chain A, upper cantilever drive chain B; Z-axis vertical lifting mechanism 2: lifting frame 2-1, frame guide rail 2-2, lifting motor 2-3, chain drive 2-4 ; fixed connection point 3 on the upper cantilever; fixed connection point 4 on the cantilever seat.

[0018] see Figure 1 to Figure 8 , the present invention includes an X-axis bidirectional drive mechanism 1 and a Z-axis vertical lifting mechanism 2 . The X-axis bidirectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com