Fatigue durability vibrating test stand of motorcycle frame

A vibration test bench, fatigue and durability technology, used in vibration testing, vehicle testing, machine/structural component testing, etc., can solve the problem that frame deformation or cracks cannot be automatically detected, recorded and alarmed, the vibration frequency cannot be automatically adjusted, and the vehicle The impact force of the frame cannot be monitored in real time, etc., to achieve the effect of reducing noise, simulating road driving, and controllable loading force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

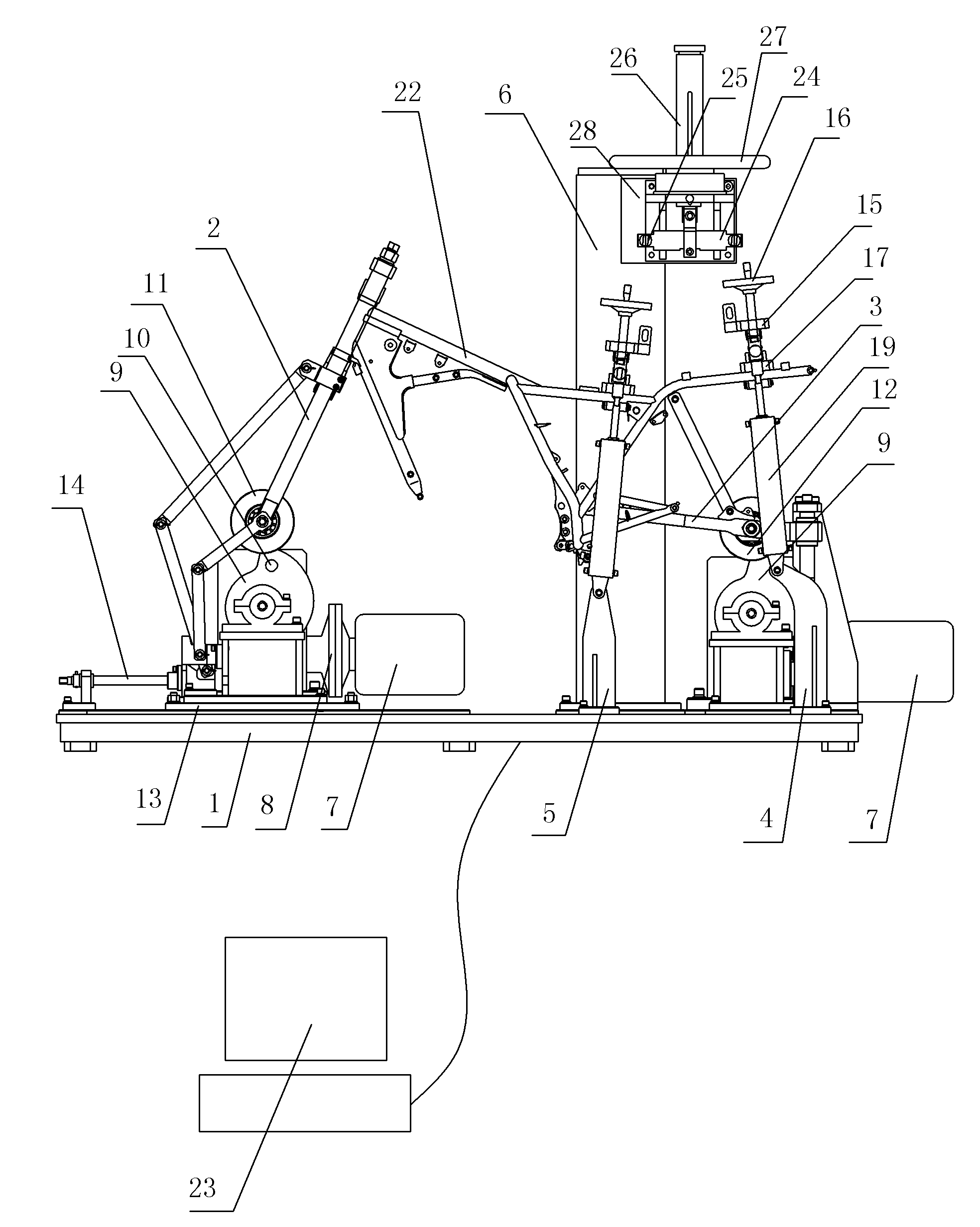

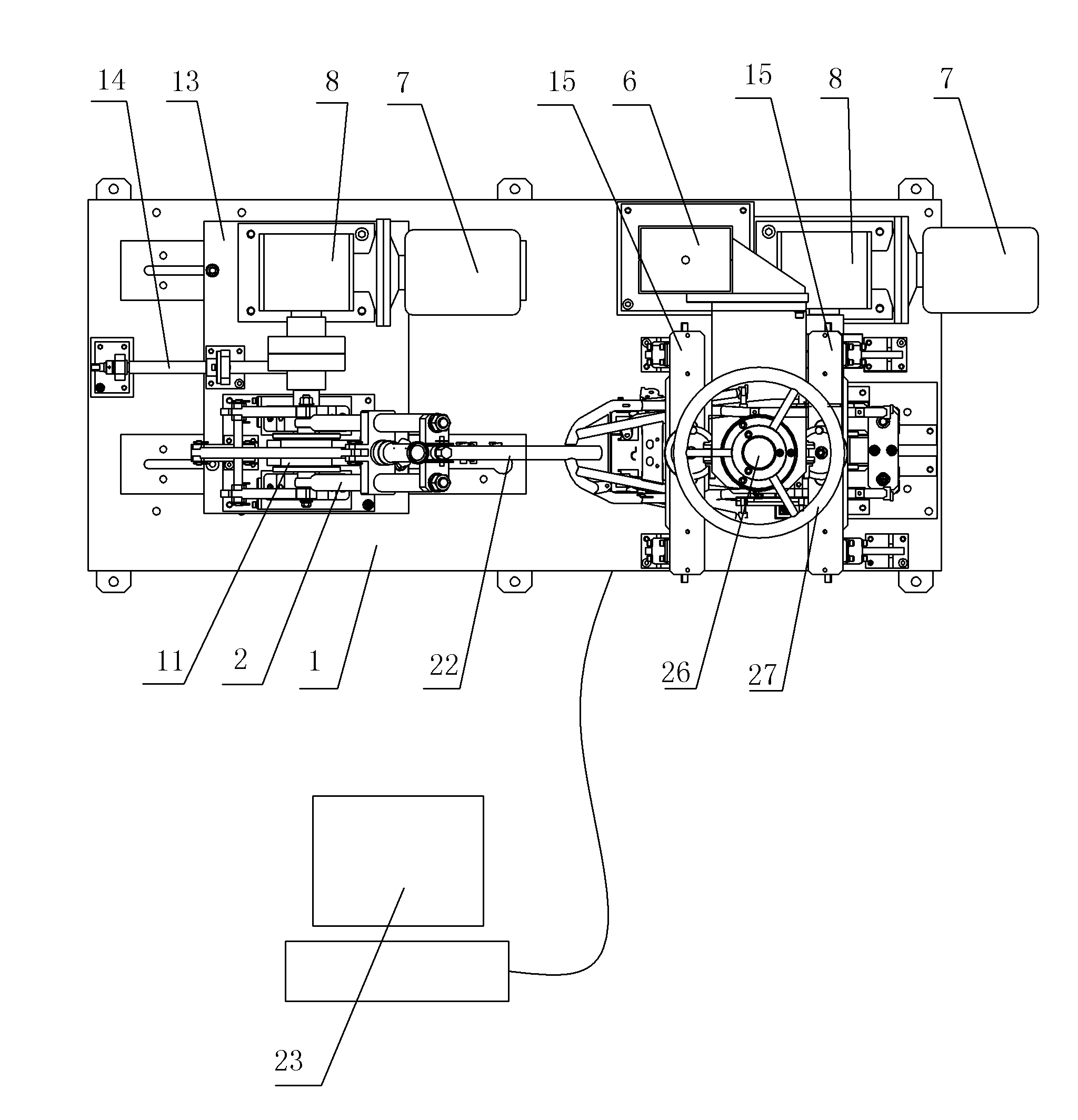

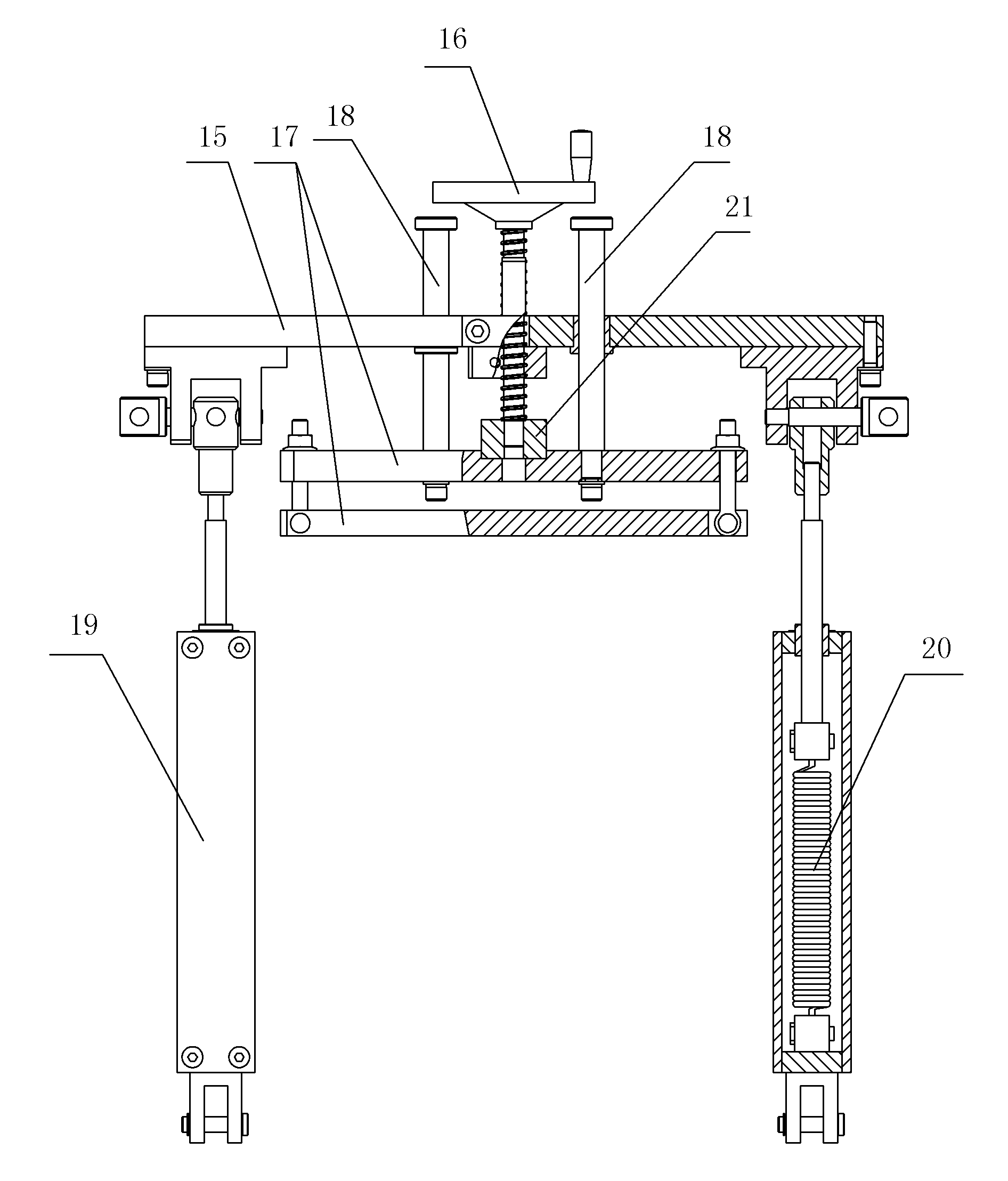

[0016] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a motorcycle frame fatigue durability vibration test bench includes a base 1, and a driving device is respectively fixed at the front and rear ends of the base 1, and the driving device is respectively connected with the front roller 11 and the rear roller 12. There are two sets of support seats, the first support seat 4 is located on both sides of the rear bracket 3, the second support seat 5 is parallel to the first support seat 4, and is located in front of the rear bracket 3, the first support seat 4 and the second support seat 5 A loading device is respectively fixed by pin shafts; a column 6 is also installed beside the second support seat 5, and a hanging device is installed on the top of the column 6, and the hanging device includes a hanger 24, and the suspension rod 24 hangs the loading device through a connecting shaft 25, Suspension rod 24 is connected with hanging handwheel 27 by screw mandrel 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com