Pneumatic telescopic center device

A pneumatic retractable, top-notch technology, applied in the direction of transportation and packaging, winding strips, thin material handling, etc., can solve inconvenience and other problems, achieve the effect of reducing waste loss, shortening downtime, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

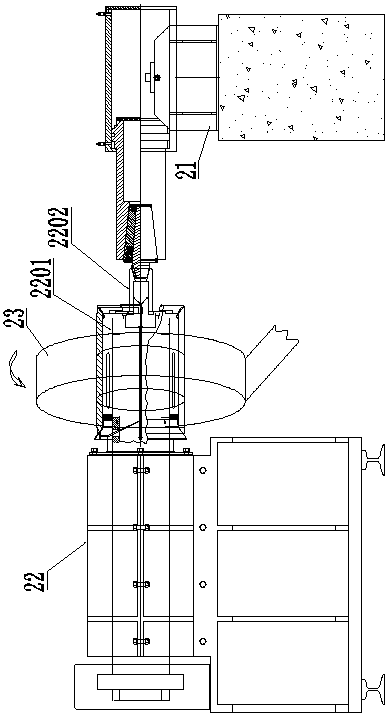

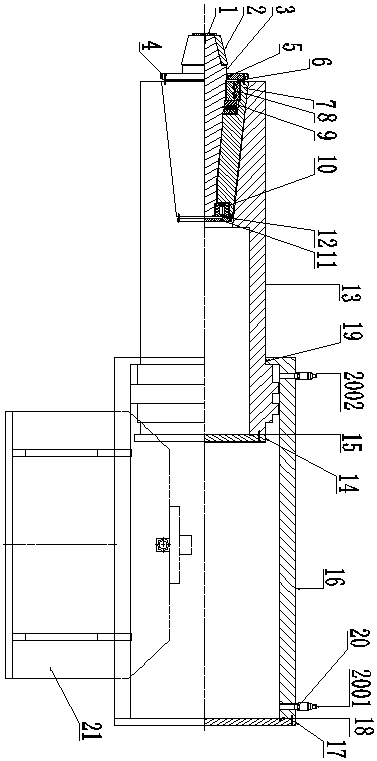

[0035] Such as figure 1 and figure 2 As shown together, the present invention provides a pneumatic retractable tip device, which includes a pneumatic unit and a tip unit, and the pneumatic unit is used to realize the telescopic function of the tip unit.

[0036] Such as figure 2 As shown, the pneumatic unit includes a cylinder assembly and a fixed seat 21; the cylinder assembly is installed on the fixed seat 21; the cylinder assembly includes a cylinder body 13, a cylinder liner 16, and a second compression sealing assembly.

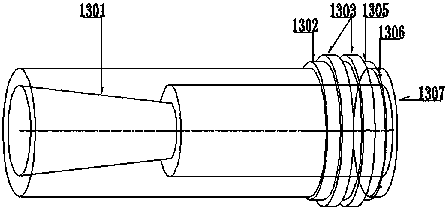

[0037] Such as image 3 As shown, the inside of the cylinder 13 is provided with a cylinder Morse taper 1301 and a cylindrical cavity; the small end surface of the cylinder Morse taper 1301 communicates with the cylindrical cavity, and the cylinder Morse taper The large end face of the taper hole of the hole 1301 coincides with one end face of the cylinder body 13; the Morse taper hole 1301 of the cylinder body is used to insert the top unit; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com