Design method for CCD (charge coupled device) counterpoint read point on exposure film

A design method and film technology, which are applied in microlithography exposure equipment, photolithographic process exposure devices, optics, etc., can solve the problems of increasing the frequency of equipment maintenance, low product yield and quality, waste of manpower and material resources, etc. Potion and labor costs, increase the effect of automatic compensation function, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

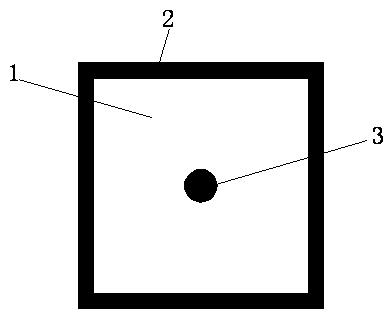

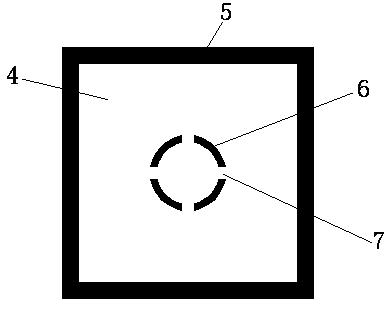

[0024] like figure 1 , figure 2 As shown, set a box 2 with a size of 6mm×6mm on the C film 1, set a 0.8mm solid circle PAD 3 in the center of the box 2, and set the line width of the box 2 to 15mil; set the size on the S film 4 It is also a square frame 5 of 6 mm×6 mm, and a hollow ring 6 is arranged in the square frame 5 , and four gaps 7 are distributed on the ring 6 . Among them, the inner diameter of the ring 6 is 1.5 mm, the outer diameter is 1.8 mm, the width of the notch 7 is 12 mil, and the line width of the box 5 is also 15 mil.

[0025] The combination of parameters in the above embodiments can increase the overall alignment accuracy of the CCD exposure machine by 10%, shorten the reading time of the CCD alignment lens of the exposure machine, and improve production efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com