Automatic control method and system for processing and preparing active carbons

An automatic control system and activated carbon technology, applied in the direction of electrical program control, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of increased labor costs, large fluctuations, large randomness, etc., and improve the acquisition rate, quality, and fluctuation range The effect of reducing and reducing the loss on ignition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

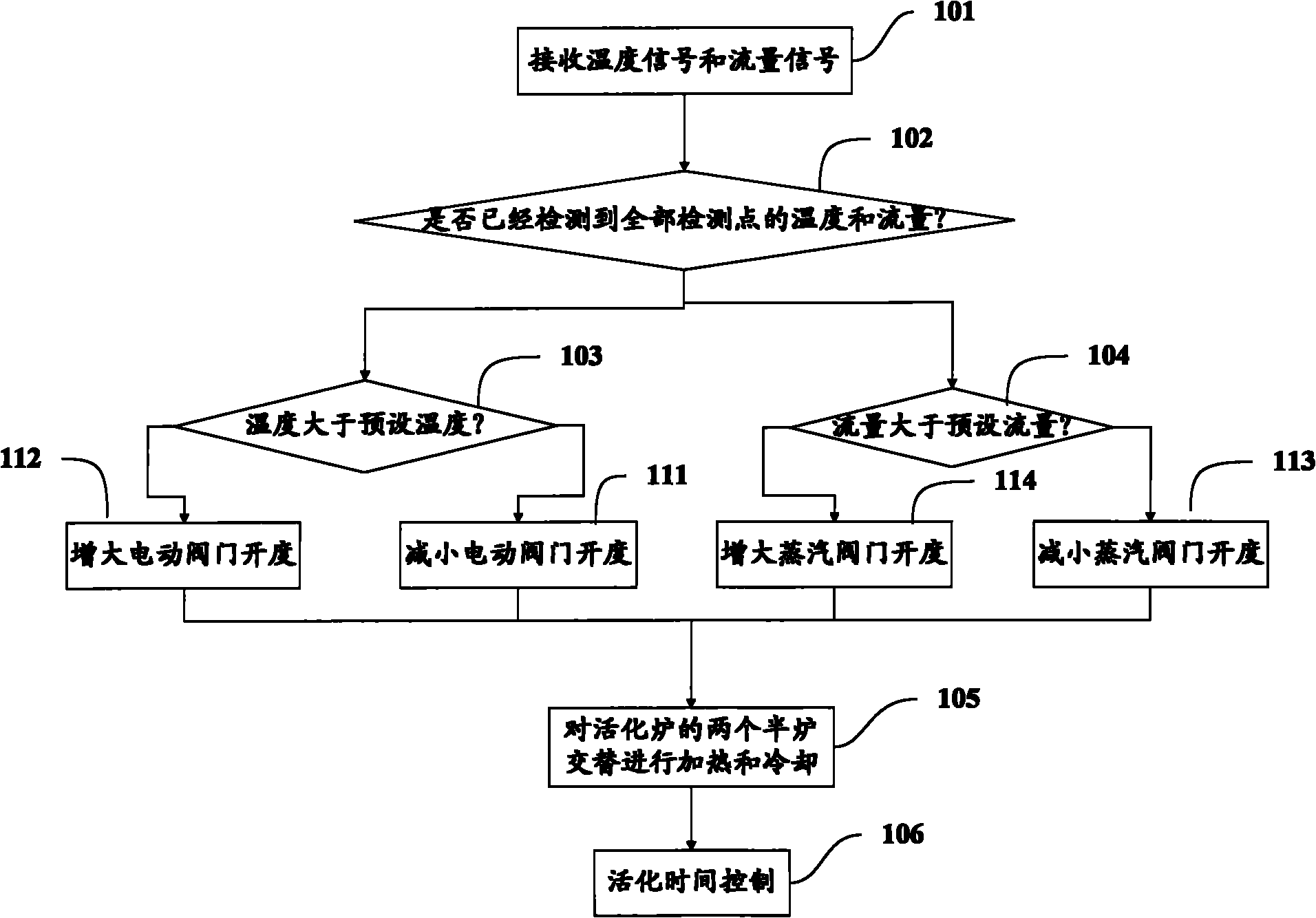

[0018] figure 1 It is a flowchart of an automatic control method for activated carbon processing and preparation in a specific embodiment of the present invention. The methods include:

[0019] In step 101, a temperature signal and a flow signal are received. The temperature signal includes the temperature of the carbonization furnace and the temperature of the activation furnace. The temperature is detected by various temperature sensors, which may be thermocouples or other temperature sensing elements.

[0020] Since there are many temperature points of the carbonization furnace and the temperature of the activation furnace to be collected, preferably, in step 102, it is necessary to determine whether the temperatures and flow rates of all detection points have been detected. Detect whether all the temperature signals and flow signals have been received, if the temperature signals of all the temperature detection points have been received, continue to the subsequent proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com