Forecast and balance method for tank level of coke oven gas of steel makers

A coke oven gas and counter technology, which is applied in the information field, can solve the problems of increasing model complexity and low accuracy of the counter prediction model, and achieves the effects of quickly balancing gas consumption, reducing scheduling workload, and reducing complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

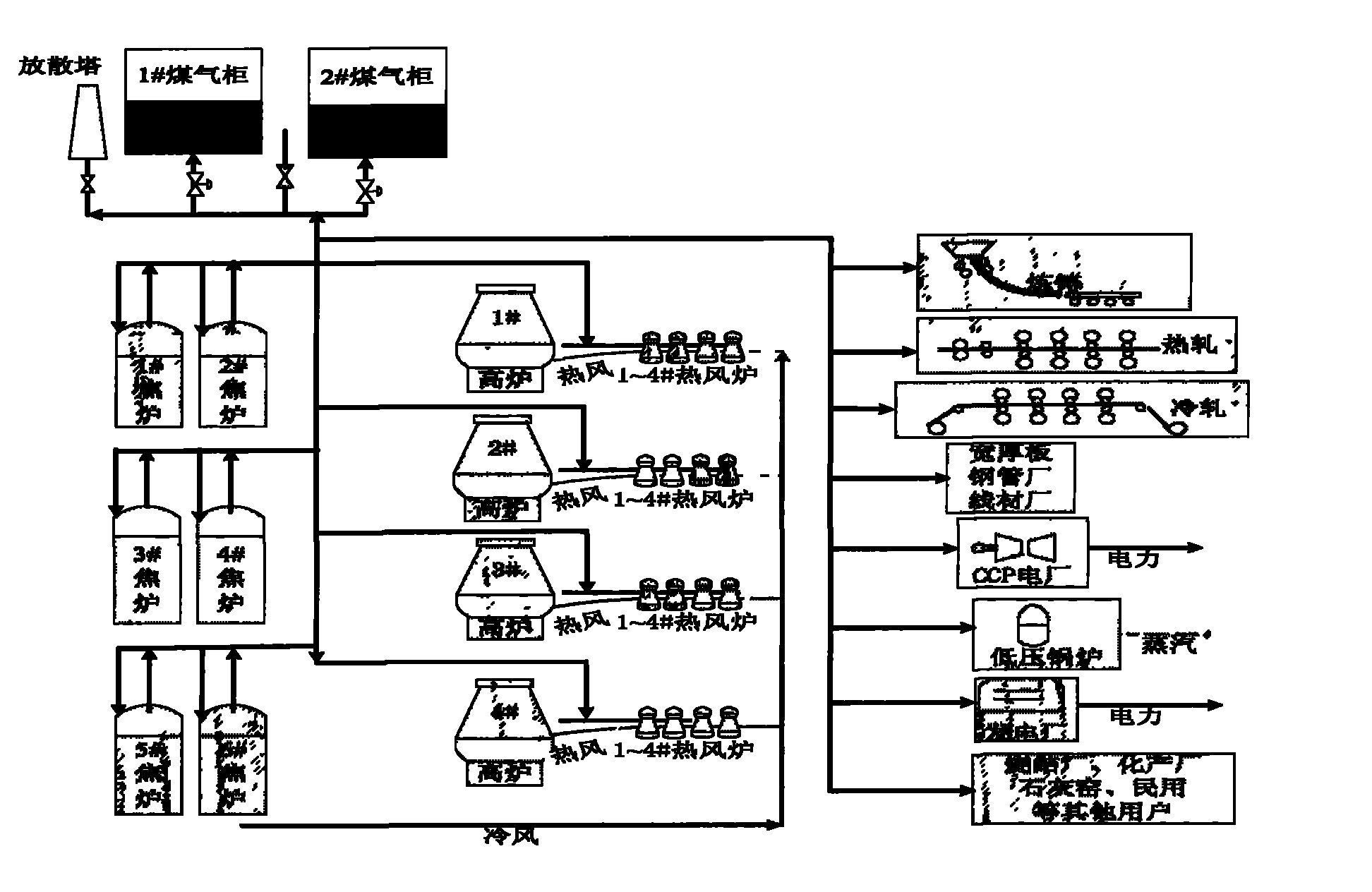

[0017] see figure 1 As shown, in an embodiment of the present invention, the coke oven gas system is composed of gas generation source, gas consumption user, gas adjustment user, gas storage equipment, gas release equipment and gas transmission pipeline network.

[0018] Most of the gas produced by the gas generation source is transported by the gas pipeline network to the gas consumer for their normal production, and the rest is stored in the gas storage equipment in the gas pipeline network - the gas cabinet. In practice, due to the different production processes of each gas user, the flow rate of the gas consumed fluctuates to varying degrees, which will lead to unbalanced production and consumption of gas, resulting in unsteady changes in gas cabinets. Due to the safe operation settings of the gas cabinet, the dispatcher needs to grasp the change of the gas cabinet in real time, adjust the gas consumption of the user in time to stabilize the gas cabinet, so as to avoid the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com