Temperature measurement charging method of storage battery

A charging method and storage battery technology, which are applied to secondary battery charging/discharging, battery circuit devices, secondary battery repair/maintenance, etc., can solve problems such as water loss during charging, and achieve easy water loss, ensure service life, and reliable The effect of sex and life guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0029] The temperature measurement and charging method of the storage battery in this embodiment includes:

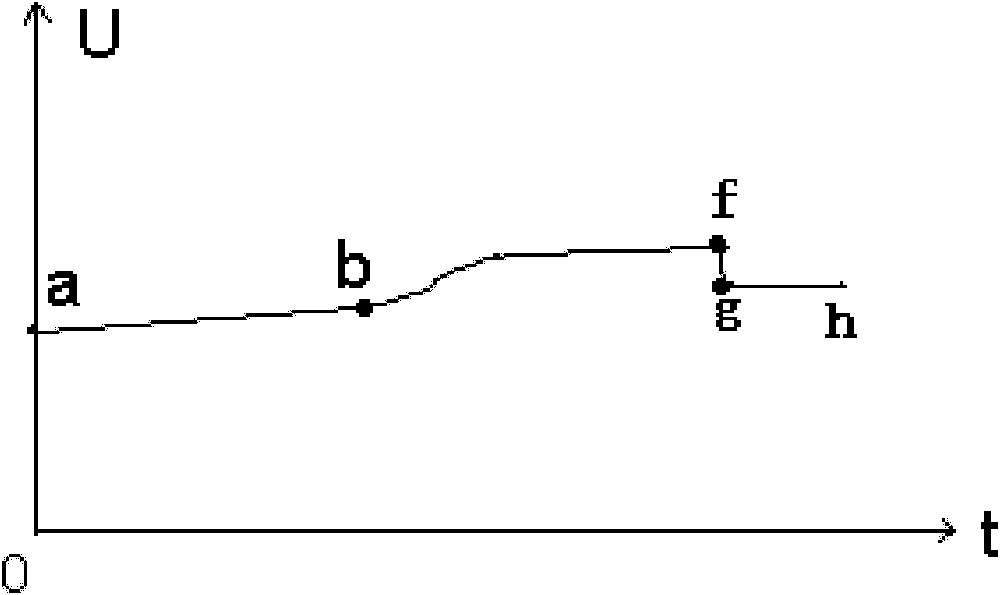

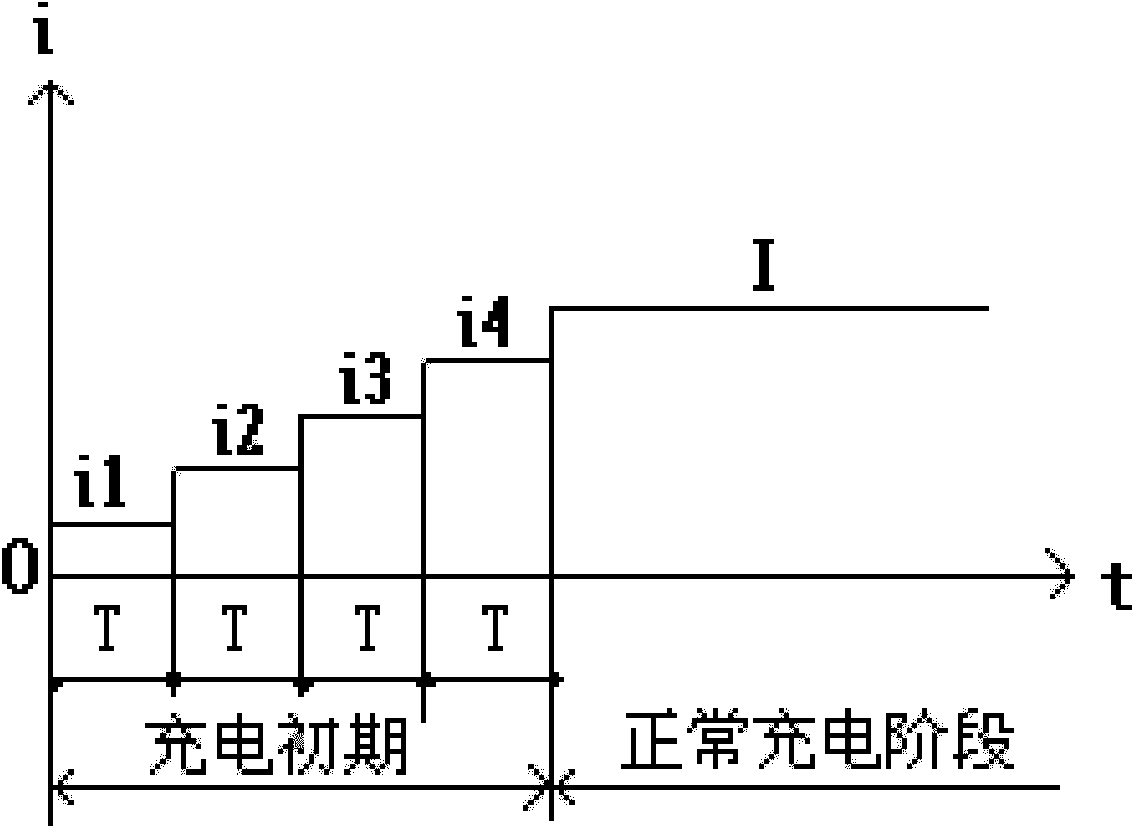

[0030] A: At the initial stage of charging, if the temperature of the electrolyte in the battery is not lower than 25°C, charge the battery with a constant current, and the charging current is 0.1C; until the voltage of the battery reaches the gassing voltage of the battery , carry out constant voltage charging; when the voltage of the battery reaches the rated saturation voltage, it will be charged after a period of floating charging; the period of time is 1-24 hours, and the current of floating charging is 0.01-0.02c; During the charging and charging process, when the temperature of the electrolyte is measured to rise, the float charging is stopped immediately to prevent the battery from overheating. Because the floating charging current is small, the floating charging voltage is generally below the gassing point voltage of the battery.

[0031] B: At the initial sta...

Embodiment 2)

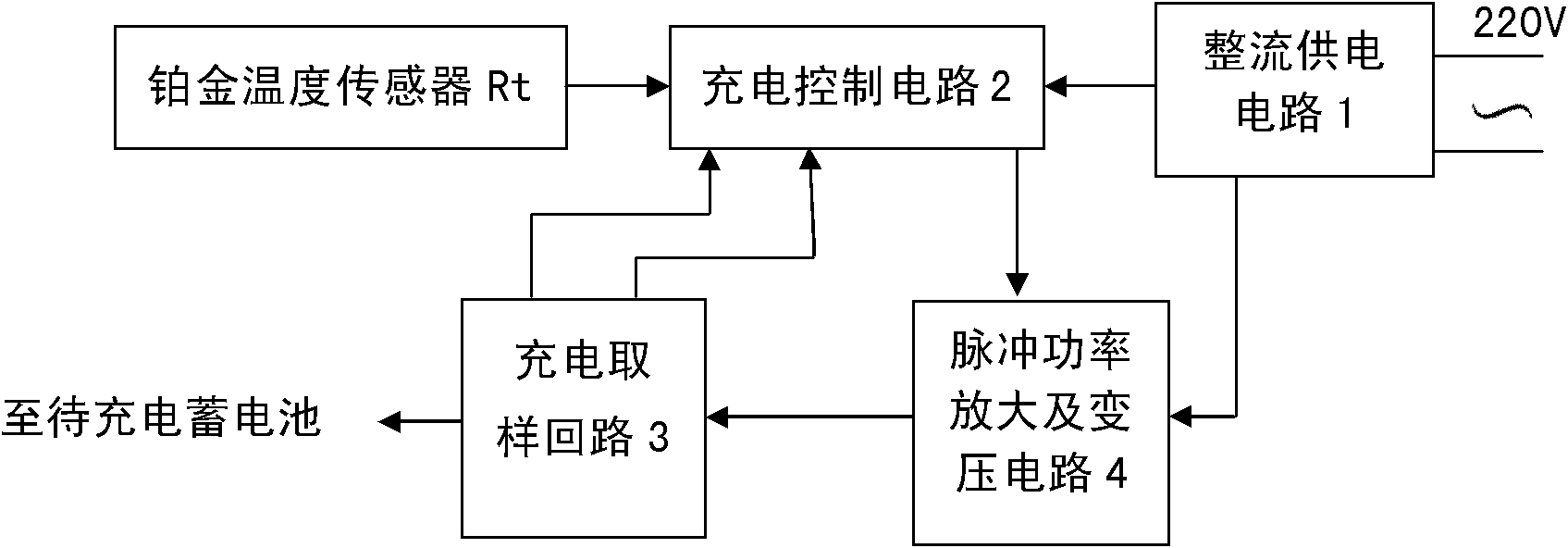

[0044] See Figure 3-5 , the charging device using the temperature measurement and charging method of the above storage battery, comprising: a rectification power supply circuit 1, a pulse power amplification and voltage transformation circuit 4 connected to the power supply output end of the rectification power supply circuit 1 for providing charging power to the storage battery, The charging sampling circuit 3 for detecting charging current and voltage, the platinum temperature sensor Rt installed in the electrolyte of the storage battery, and the feedback signal used to control the pulse power amplification and voltage transformation circuit 4 in real time through the charging sampling circuit The charging control circuit 2 of the output voltage; the charging control circuit 2 is suitable for the actual temperature of the battery electrolyte measured by the platinum temperature sensor, and the corresponding charging procedure in the first embodiment is adopted.

[0045] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com