Teflon fixture and its application for wet process of semiconductor micro-nano devices

A wet process, Teflon clip technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of hindering ultraviolet light passing through, lithography failure, etc., to achieve the effect of convenient operation and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below with reference to the accompanying drawings and embodiments.

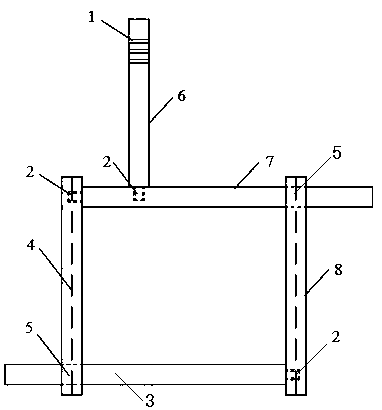

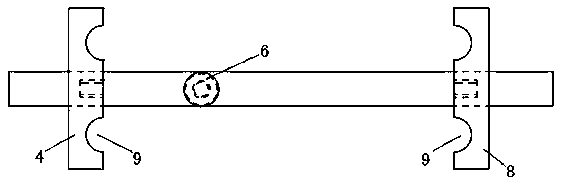

[0050] like figure 1 and figure 2 As shown, a kind of Teflon clamp for wet process of semiconductor micro-nano device includes a first clamping plate 4, a second clamping plate 8, a first sliding rod 7, a second sliding rod 3 and a handle 6, the first clamping plate 4 It is arranged in parallel with the second plywood 8, one end of the first sliding rod 7 is vertically fixed on the first plywood 4, the other end is matched with the second plywood 8, and one end of the second sliding rod 3 is vertically fixed on the second plywood 8 , the other end fits through the first clamp plate 4 (the first clamp plate 4 is provided with a through hole 5 that cooperates with the second slide bar 3, and the second clamp plate 8 is provided with a through hole 5 that cooperates with the first slide bar 7) , the handle 6 is fixed on the first sliding rod 7 (the handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com