A carbon dioxide anhydrous fracturing fluid conductivity test system

An anhydrous fracturing fluid and testing system technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., to achieve uniform properties and maintain system safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

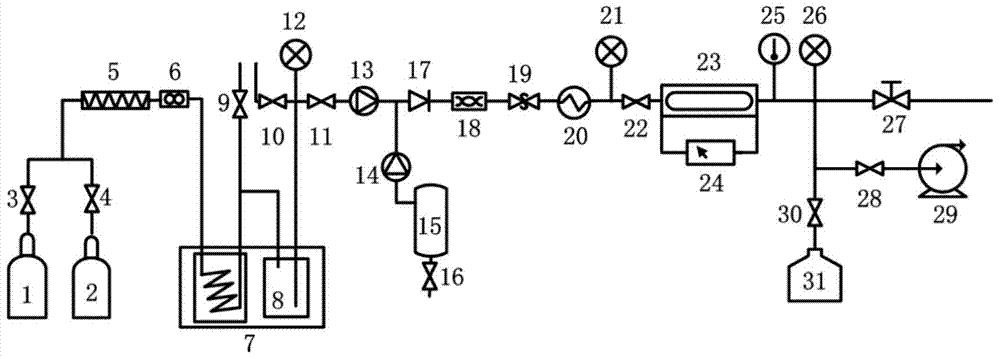

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] As shown in the drawings, a carbon dioxide anhydrous fracturing fluid conductivity test system includes a gas purifier 5, the inlet of the gas purifier 5 passes through the first valve 3, the second valve 4 and the first gas cylinder 1 respectively, The second gas cylinder 2 is connected, and after being purified by the gas purifier 5, the outlet of the gas purifier 5 passes through the liquid CO in the flow meter 6 and the refrigeration system 7. 2 Inlet connection of storage tank 8, refrigeration part of refrigeration system 7 and liquid CO 2 The pipeline between the inlets of the storage tank 8 is connected to the inlet of the third valve 9, and the outlet of the third valve 9 is connected to the atmosphere, and the liquid CO 2 The outlet of the storage tank 8 is connected to the inlet of the fourth valve 10, the first pressure gauge 12 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com