PEEP (positive end expiratory pressure) valve and respirator with same

A ventilator and valve core technology, applied in the direction of respirators, etc., can solve the problems of inability to use low-end and emergency ventilators, poor stability and reliability of external PEEP, high requirements for electronic PEEP matching, and achieve simple design and solution The effect of poor stability, reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

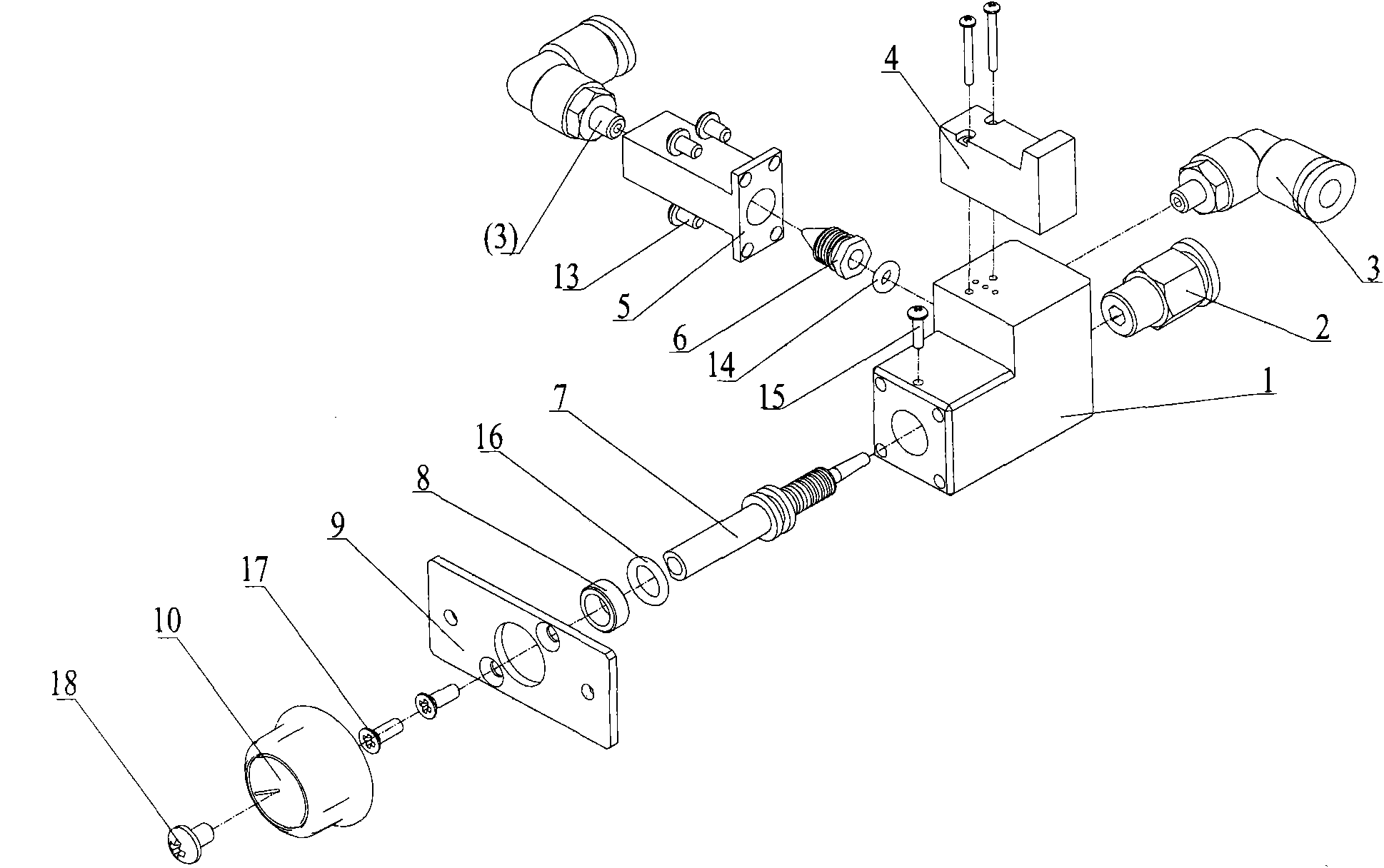

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. The same components are denoted by the same reference numerals in the drawings.

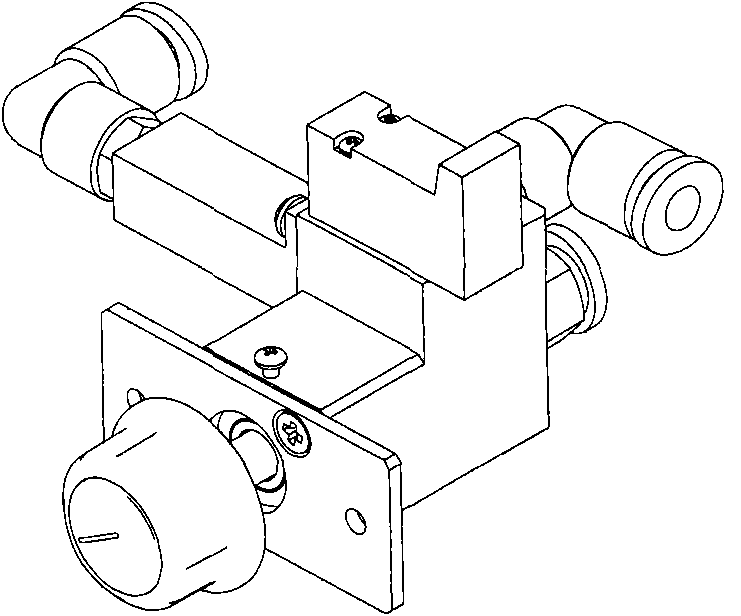

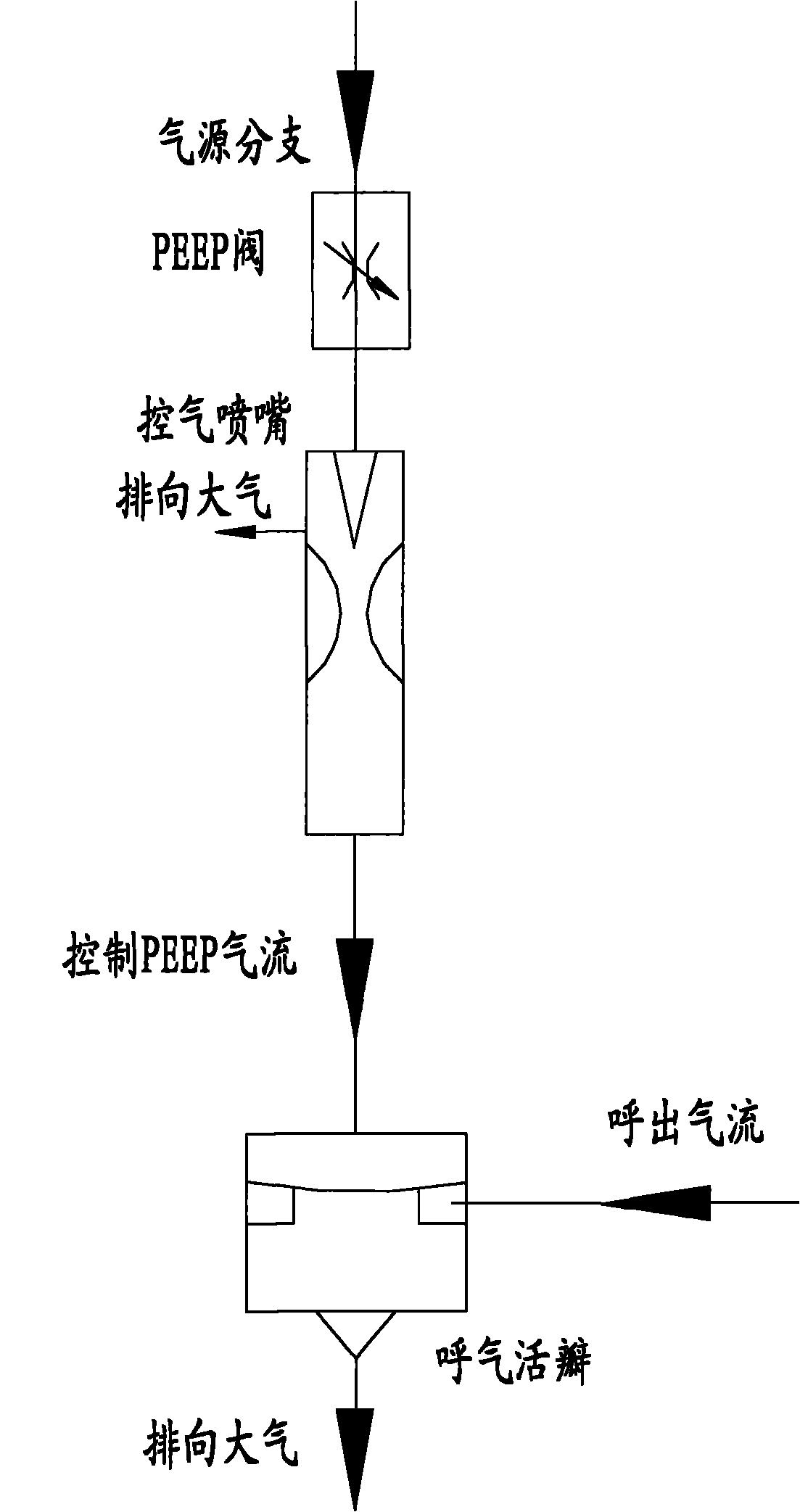

[0031] refer to figure 1 with 2 , A PEEP valve according to an embodiment of the present invention mainly includes a throttling part, an air control part, and a regulating installation part. The throttling part includes: throttle body 1, push-in connector 2, push-in connector 3, solenoid valve 4, throttle spool 7, PEEP valve adjustment positioning sleeve 8, O-shaped rubber sealing ring 16, screw 17 , screw 18, and the air control part includes: air control valve body 5, air control valve core 6, screw 13, O-shaped rubber sealing ring 14, screw 15, and the adjustment installation part includes: knob 10, mounting plate 9.

[0032] The inlet end of the throttle part is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com