Intelligent pressing device and method of eccentric shaft and bearing

A technology of press-fitting device and eccentric shaft, which is applied in the field of bearing assembly, can solve the problems that the orientation cannot be adjusted, the crank is difficult to realize automatic press-fitting, and the degree of automation is not high, so as to achieve the effect of automatic control of the press-fitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

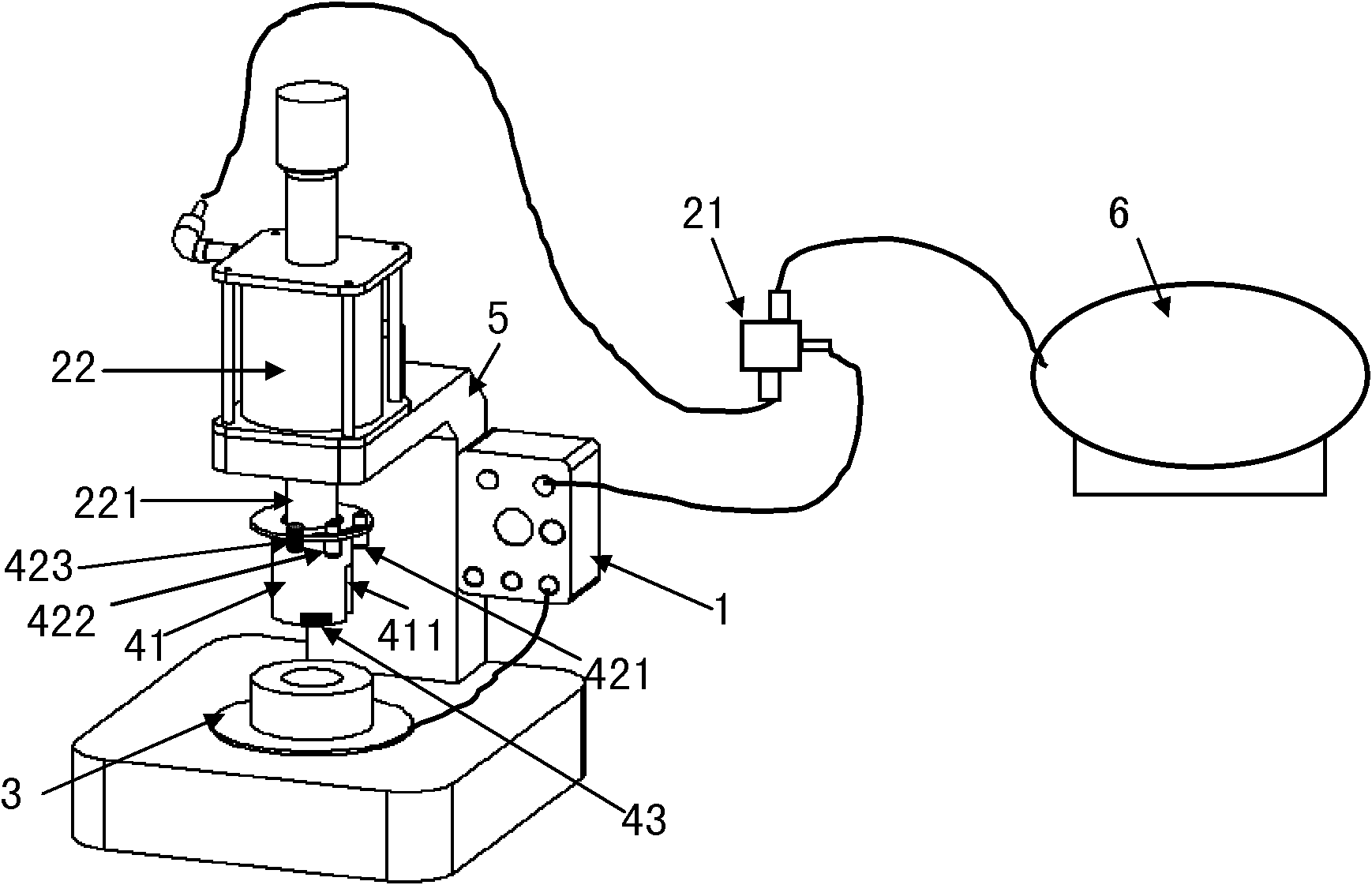

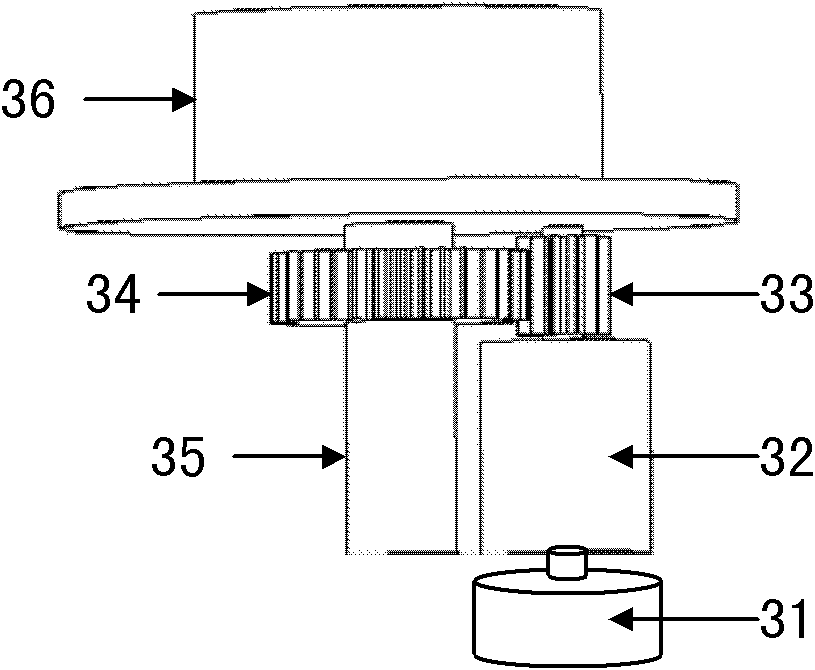

[0060] figure 1 It is a schematic diagram of an eccentric shaft and bearing intelligent press-fitting device of the present invention, including a control circuit box 1, a servo valve 21, a servo cylinder 22, a piston rod 221, a rotary table 3, a motor 31, a pressure plate 41, and a first sensor 421 , the second sensor 422, the third sensor 423, the pressure sensor 43, the support 5 and the air pump 6, the control circuit box 1 includes a microprocessor chip 11, a servo valve drive circuit 12, a motor drive circuit 13 and a distance signal acquisition circuit 14 , wherein: the pressure plate 41 is a hollow cylinder, the outer diameter of the cylinder is smaller than the outer diameter of the shaft; the inner diameter of the cylinder is approximately two-thirds of the outer diameter; there is a groove 411 on the hollow cylinder, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com