Vaned petrol engine

A gasoline engine, vane type technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems that triangular rotor engines are not widely used, cannot be made into high-power engines, and the structure of triangular rotors is complex. Low thermodynamic efficiency, suitable for mass production and assembly, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

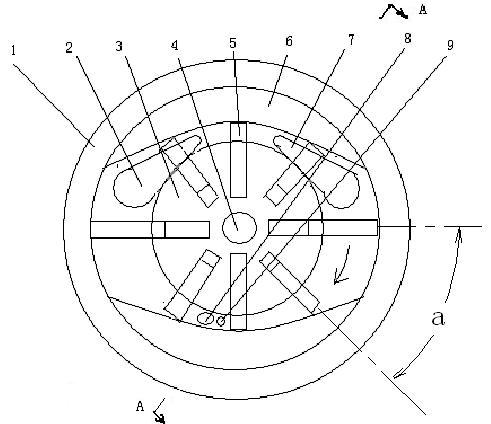

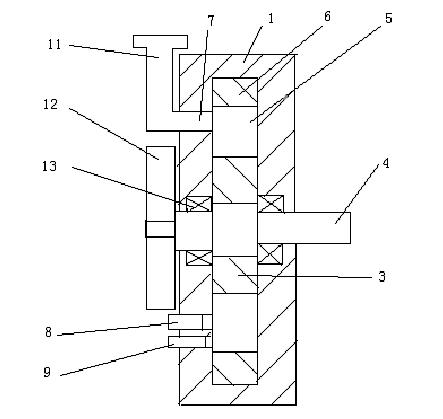

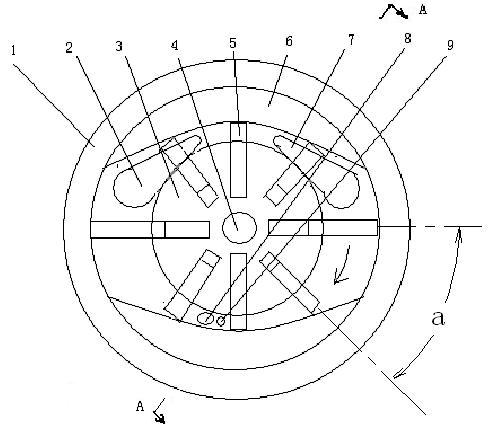

[0017] like figure 1 and figure 2 As shown, a vane gasoline engine of the present invention includes a stator 1 , a rotor 3 arranged in the inner cavity of the stator 1 , an exhaust hole 2 , an air intake hole 7 , an electronically controlled gasoline nozzle 9 and a spark plug 8 . The stator 1 includes an inner cavity with a circular cross section and two crescent-shaped arc plates 6 symmetrically arranged on the upper and lower ends of the inner cavity; The radii of the inner cavity are equal, and the inner arc surface is sequentially composed of a constant acceleration arc surface and a constant deceleration arc surface along the circumferential direction clockwise, and a transition arc surface is provided between the constant acceleration arc surface and the constant deceleration arc surface, etc. Between the acceleration arc surface and the inner cavity of the stator 1, and between the constant deceleration arc surface and the inner cavity of the stator 1, transition arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com