Material testing machine-based ball screw assembly axial static stiffness testing clamp

A technology of ball screw pair and material testing machine, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, measuring devices, etc., can solve the problems of high cost, single loading form, immature technical means, etc. To achieve the effect of improved precision and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

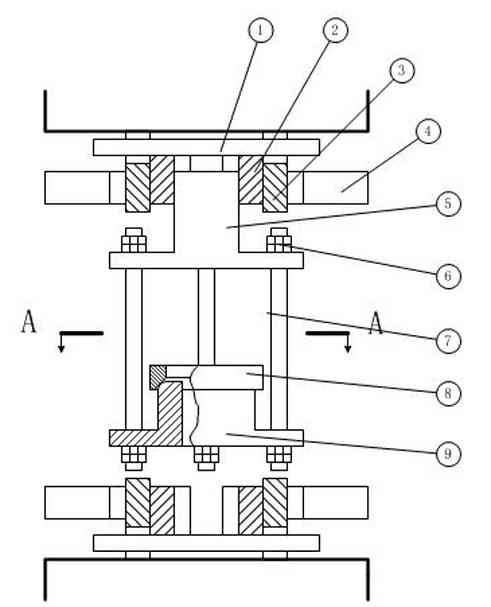

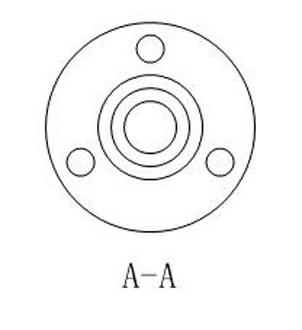

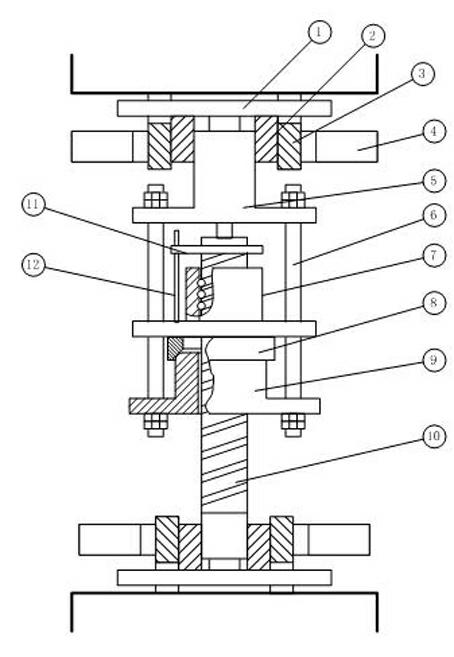

[0015] A test fixture for axial static stiffness of a ball screw pair based on a material testing machine, comprising: a pull-up block 5, on which at least two pull rods 6 are arranged, and one end of the pull rod 6 is connected to the pull-up block 5 , the other end of the pull rod 6 is connected with a briquetting block 9, the briquetting block 9 is provided with an inner hole 91 for the ball screw to be tested to pass through, and the upper end of the briquetting block 9 is a round chamfer 92. The briquetting block 9 is provided with an adjusting block 8, and the adjusting block 8 is provided with an inner hole 81 through which the ball screw to be measured passes. The rounded corners 92 are in contact with each other, and the adjusting block 8 is provided with a nut 7 for connecting the ball screw to be tested. In this embodiment, three pull rods 6 are provided on the upper pull block 5 .

[0016] The measurement method is as follows:

[0017] Using this fixture to measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com