Method for arranging heat in steel making continuous casting production process

A production process, steelmaking and continuous casting technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effects of accelerating global optimization capabilities, accelerating convergence speed, and improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

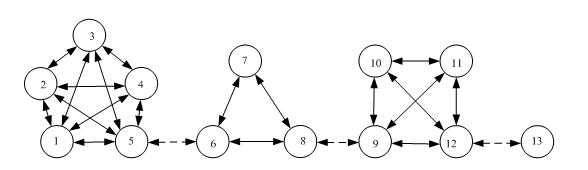

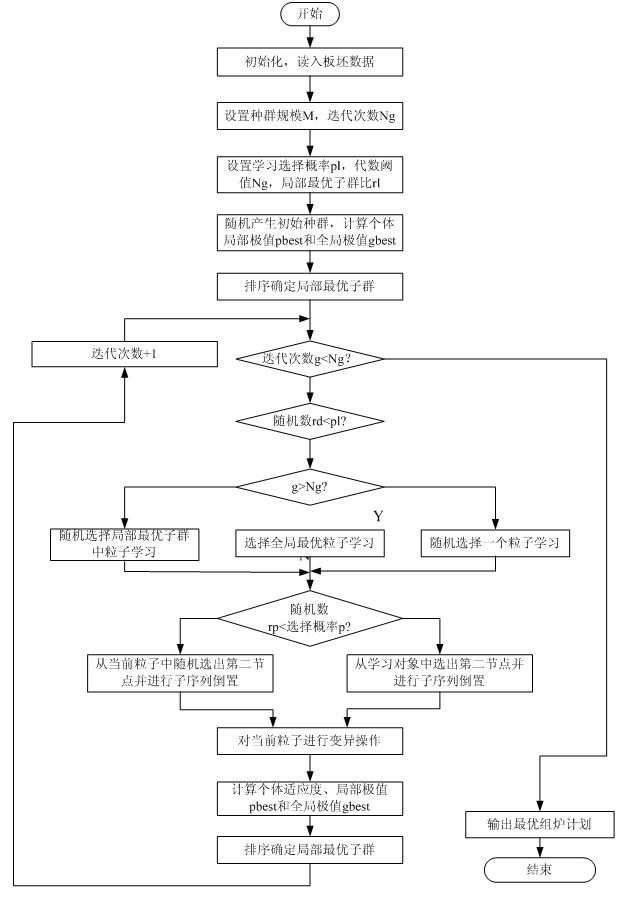

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0061] After receiving a batch of orders, the factory must first go through quality and production design to turn the order into a producible contract, and then close the contract through the contract, that is, select the meeting date from the given production contract according to the priority of the delivery date The contract slab of production capacity is imported into the local database;

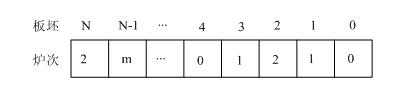

[0062] Hundreds of thousands of slabs obtained through material design, the steps for slab group furnace are:

[0063] Firstly, the furnace slab to be assembled must be selected from the pool, and the furnace planning model should be established. The furnace plannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com