Flow field plate

A flow field plate and flow channel technology, applied in the field of flow field plate, can solve the problems affecting fuel cell performance, reaction fluid flow rate and uneven concentration distribution, so as to avoid uneven concentration distribution, improve overall performance, and reduce flow rate. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

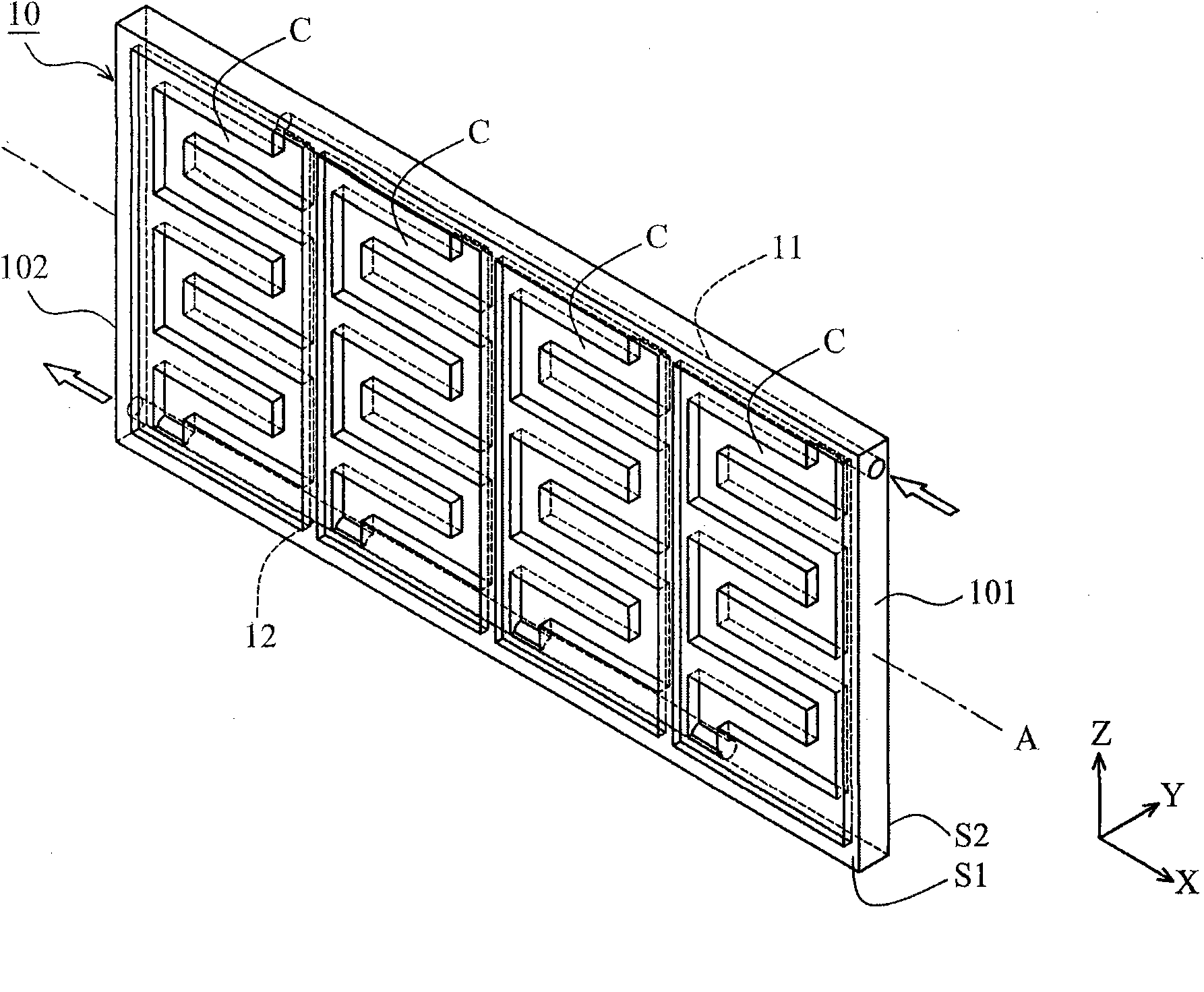

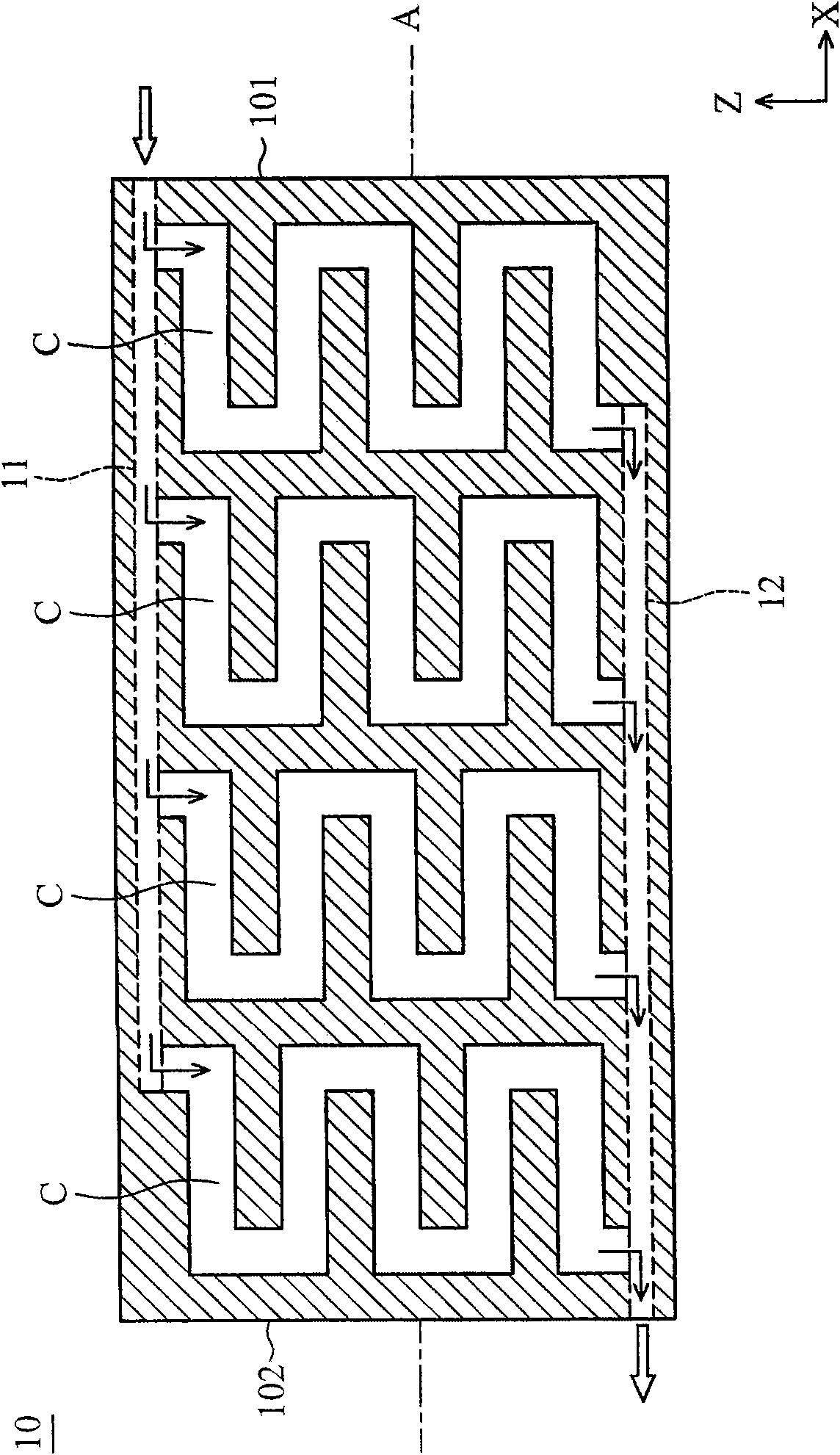

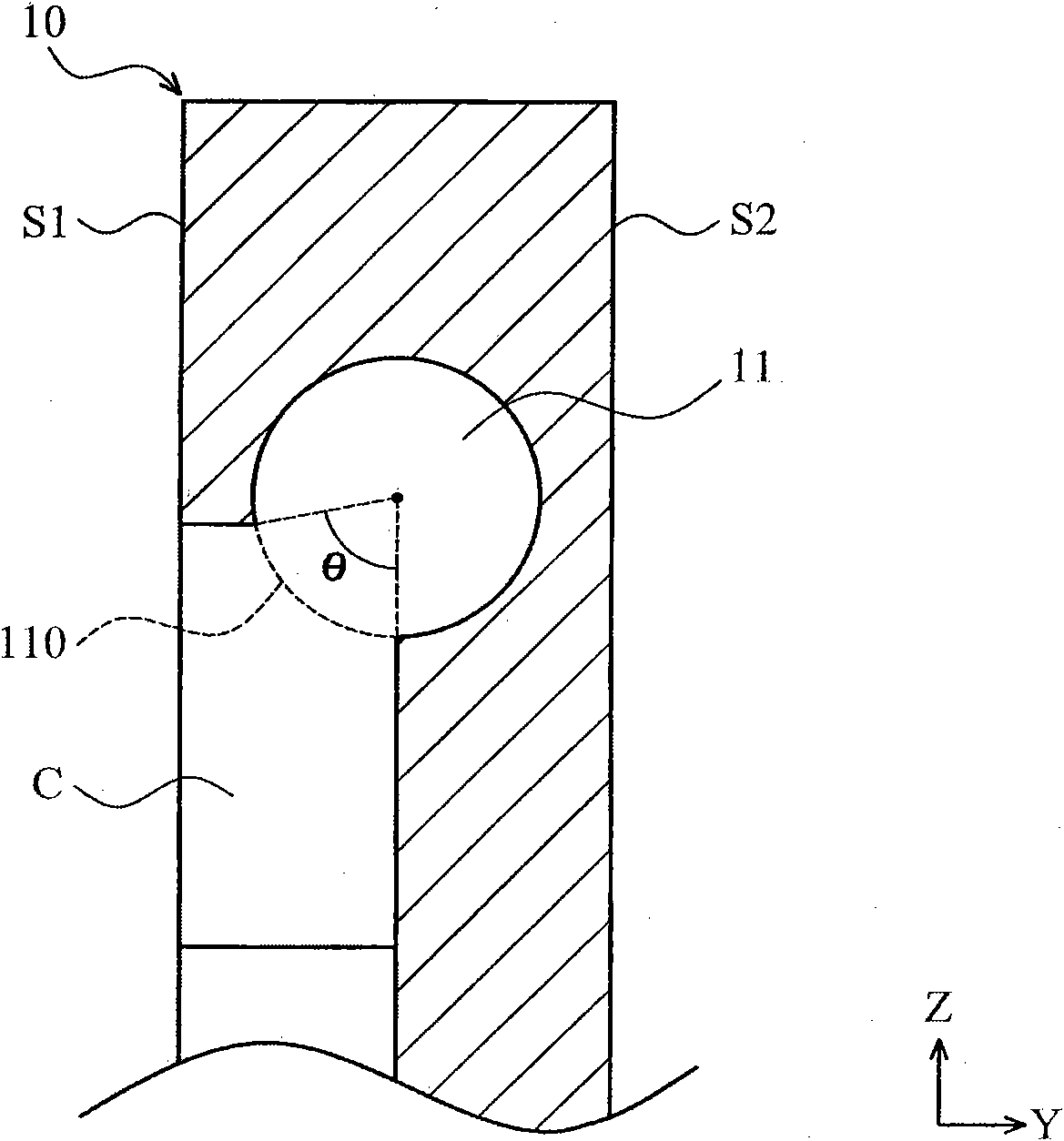

[0056] Please refer to it first Figure 1A , 1B , The flow field plate 10 of an embodiment of the present invention is mainly arranged in a flat fuel cell device, which is roughly a rectangular structure, and a single or multiple flow channels C ( flow channel), in addition, a first manifold 11 and a second manifold 12 are formed inside the flow field plate 10. Such as Figure 1A As shown, the aforementioned flow channels C are arranged along the direction of a central axis A of the flow field plate 10 and are exposed on the first side S1 of the flow field plate 10, and the aforementioned first and second manifolds 11 and 12 are formed in the flow field. The inside of the plate 10 is approximately parallel to the central axis A, and the first and second manifolds 11 and 12 communicate with the respective flow channels C respectively.

[0057] It should be specifically noted that a reactant fluid of the aforementioned fuel cell device can enter the first manifold 11 from the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com