Camshaft adjustment device for an internal combustion engine

一种凸轮轴调节、调节装置的技术,应用在阀装置、机械设备、发动机元件等方向,能够解决动力变差、提高制造成本、关闭等问题,达到避免控制装置、短反应时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

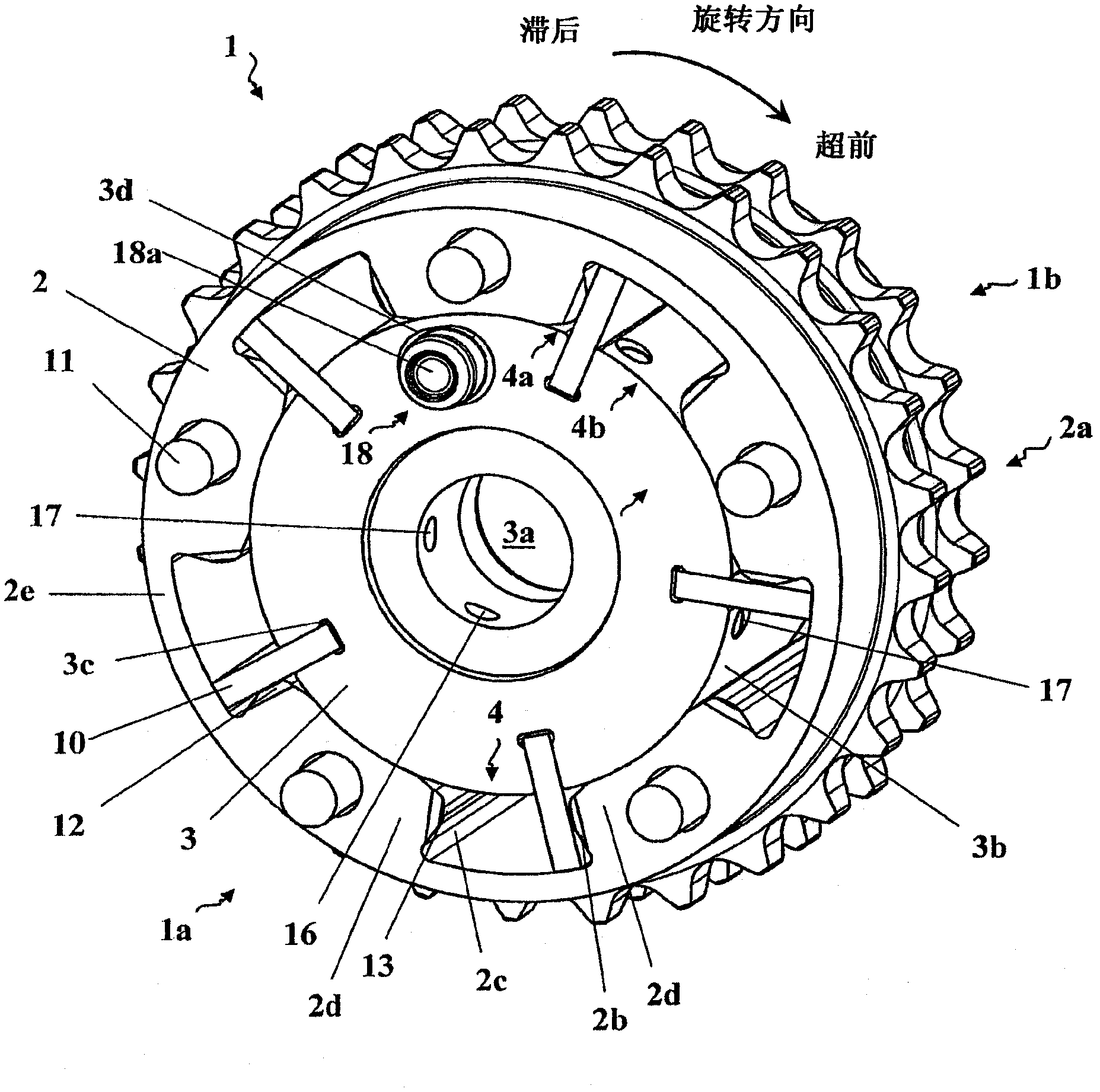

[0022] figure 1 The hydraulic camshaft adjusting device 1 is shown in a perspective view without the front cover on the side 1a facing away from the engine. The camshaft adjusting device 1 has a transmission wheel 2 mounted on an output element 3 so that it can rotate therewith. The transmission wheel drives the illustrated sprocket connected to the transmission wheel 2 via the meshing portion 2a, and its meshing teeth can mesh with a chain driven by a crankshaft not shown. However, it is also conceivable that the transmission wheel 2 is driven by a belt or a gear. The driven part 3 is designed as an impeller and is connected to a camshaft (not shown) in a rotationally fixed manner via a central receptacle 3 a, for example by means of screws or welding. Five vanes 10 that are symmetrically distributed on the circumference and extend radially are formed on the driven member 3 . Proceeding from the outer circumference 3 b , the driven element 3 has axially running vane groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com