Incompletely plasticized plastic granulator and granulating method thereof

A granulator and plastic technology, which is applied in the field of incompletely plasticized plastic granulator and its granulation, can solve the problems of changing the volume of the screw groove and the improvement of the production capacity of the plastic granulator is not very helpful, so as to improve the production efficiency. and production capacity, good promotion value and market value, quality and value assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

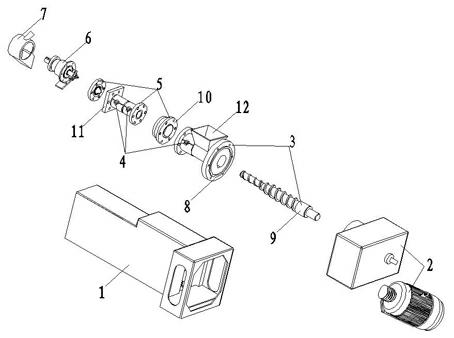

[0025] see figure 2 , the incompletely plasticized plastic granulator in the present invention comprises a frame 1, a power unit 2, a feeding device 3, a heating device 4, an extruding device 5, a pelletizing device 6 and a discharging device 7, the feeding device The feeding device 3 includes the first section of the screw sleeve 8 and the front part of the screw rod 9;

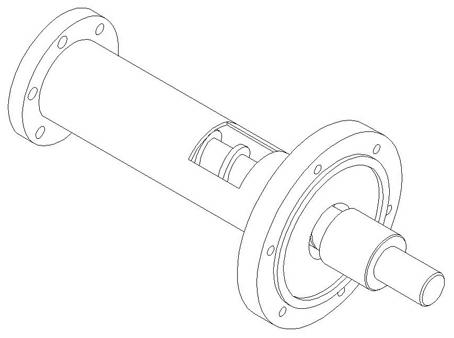

[0026] The screw 9 passes through the first segment of the screw sleeve 8, the second segment of the screw sleeve 10 and the third segment of the screw sleeve 11 from front to back; Large, the middle part of the screw rod 9 is in the shape of a tapered outer diameter gradually decreasing from front to back.

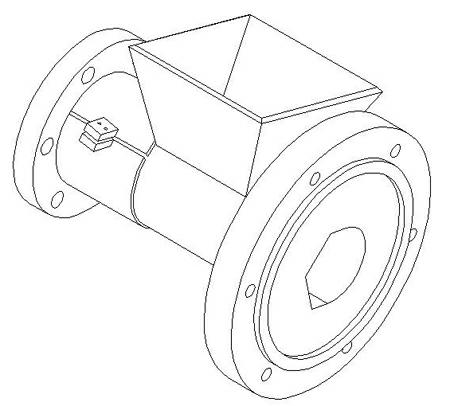

[0027] see image 3 , the first section of the screw sleeve 8 is provided with a square feeding port 12, the cross-sectional shape of the inner diameter of the first section of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com