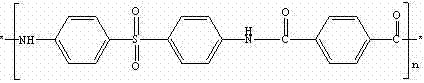

Water-proof and air-permeable coating process based on polysulfonamide fabric

A waterproof and breathable polysulfone fiber technology, which is applied in the field of waterproof and breathable coating technology, can solve the problems of high moisture regain and unfavorable use of polysulfone fibers, and achieve the effect of overcoming moisture resistance and good waterproof and breathable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Use 35g of LAG-710A to carry out water-repellent treatment on the sulfonamide fabric, and pad it once on the MU504-A bench-top padding machine, and the rolling liquid rate is 70%;

[0026] 2) Dry at l10°C for 90s and bake at l60°C for 1min;

[0027] 3) Prime the fabric with PU-9 adhesive and coating agent successively, and dry at 90°C for 2 minutes;

[0028] 4) Intermediate coat the fabric with PU-9 adhesive and coating agent successively, and dry at 100°C for 3 minutes;

[0029] 5) Surface-coat the fabric with PU-9 adhesive and coating agent successively, and dry at 150°C for 4 minutes to obtain a sulfonamide waterproof and breathable fabric.

[0030] The prepared sulfonamide waterproof and breathable fabric structure comprises: a fabric layer, an adhesive layer and a coating layer, wherein the adhesive layer and the coating layer are alternately distributed successively.

[0031] The waterproof and breathable indicators of the coated sulfonamide fabric obtained a...

Embodiment 2

[0033] 1) Use 32g of LAG-710A to carry out water-repellent treatment on the sulfonamide fabric, and pad it once on the MU504-A bench-top padding machine, and the rolling liquid rate is 65%;

[0034] 2) Dry at l10°C for 100s and bake at l60°C for 1min;

[0035] 3) Prime the fabric with PU-9 adhesive and coating agent successively, and dry at 85°C for 2 minutes;

[0036] 4) Intermediate coat the fabric with PU-9 adhesive and coating agent successively, and dry at 95°C for 3 minutes;

[0037] 5) Surface-coat the fabric with PU-9 adhesive and coating agent successively, and dry at 145°C for 4 minutes to obtain the sulfonamide waterproof and breathable fabric.

[0038] The prepared sulfonamide waterproof and breathable fabric structure comprises: a fabric layer, an adhesive layer and a coating layer, wherein the adhesive layer and the coating layer are alternately distributed successively.

[0039] The waterproof and air-permeable indicators of the coated sulfonamide fabric obtai...

Embodiment 3

[0041] 1) Use 38g of LAG-710A to carry out water-repellent treatment on the sulfonamide fabric, and pad it once on the MU504-A bench-top padding machine, and the rolling liquid rate is 75%;

[0042] 2) Dry at l10°C for 80s and bake at l60°C for 1min;

[0043] 3) Prime the fabric with PU-9 adhesive and coating agent successively, and dry at 95°C for 2 minutes;

[0044] 4) Intermediate coat the fabric with PU-9 adhesive and coating agent successively, and dry at 105°C for 3 minutes;

[0045] 5) Surface-coat the fabric with PU-9 adhesive and coating agent successively, and dry at 155°C for 4 minutes to obtain the waterproof and breathable sulfonamide fabric.

[0046] The prepared sulfonamide waterproof and breathable fabric structure comprises: a fabric layer, an adhesive layer and a coating layer, wherein the adhesive layer and the coating layer are alternately distributed successively.

[0047] The waterproof and air-permeable index of the polysulfone fiber fabric obtained af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com