Vibration absorber with adjustable frequency installed on suspended support of automobile

A car suspension and bracket technology, applied in the field of shock absorbers, can solve problems such as time-wasting and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

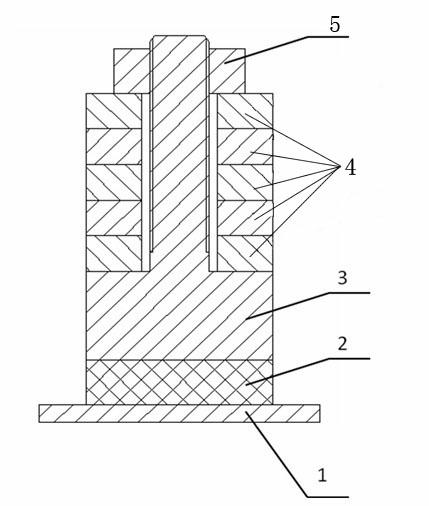

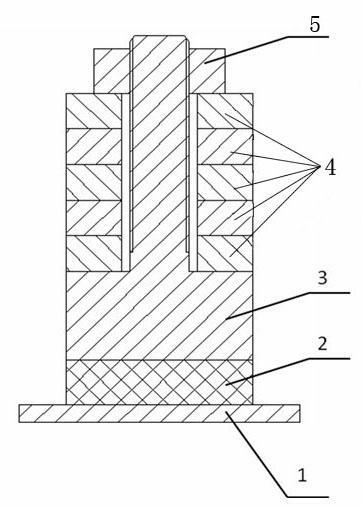

[0011] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

[0012] see figure 1 , the frequency adjustable vibration absorber is composed of a rubber spring and a mass block, including a base 1, a rubber block 2, a fixed weight block 3, a variable mass block 4, and a nut 5. The base 1 is fixed on the support of the transmission system with glue, the rubber block 2 and the base 1 are firmly pasted with glue, the lower end of the fixed mass block 3 and the rubber block 2 are firmly bonded with glue, and the upper end has a threaded rod. There are five variable mass blocks 4, which are installed on the threaded rods on the fixed mass block 3, increase or decrease according to actual needs, and are fixed on the fixed mass block 3 by nuts 5. The frequency of this dynamic vibration absorber can be adjusted to six frequencies for direct selection during testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com