Improved type triaxial apparatus

A technology of triaxial instrument and triaxial pressure, which is applied in the direction of testing material strength by applying stable shear force, can solve the problems of triaxial instrument difficult to popularize and low efficiency, so as to save testing time, reduce cost and utilize The effect of space and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

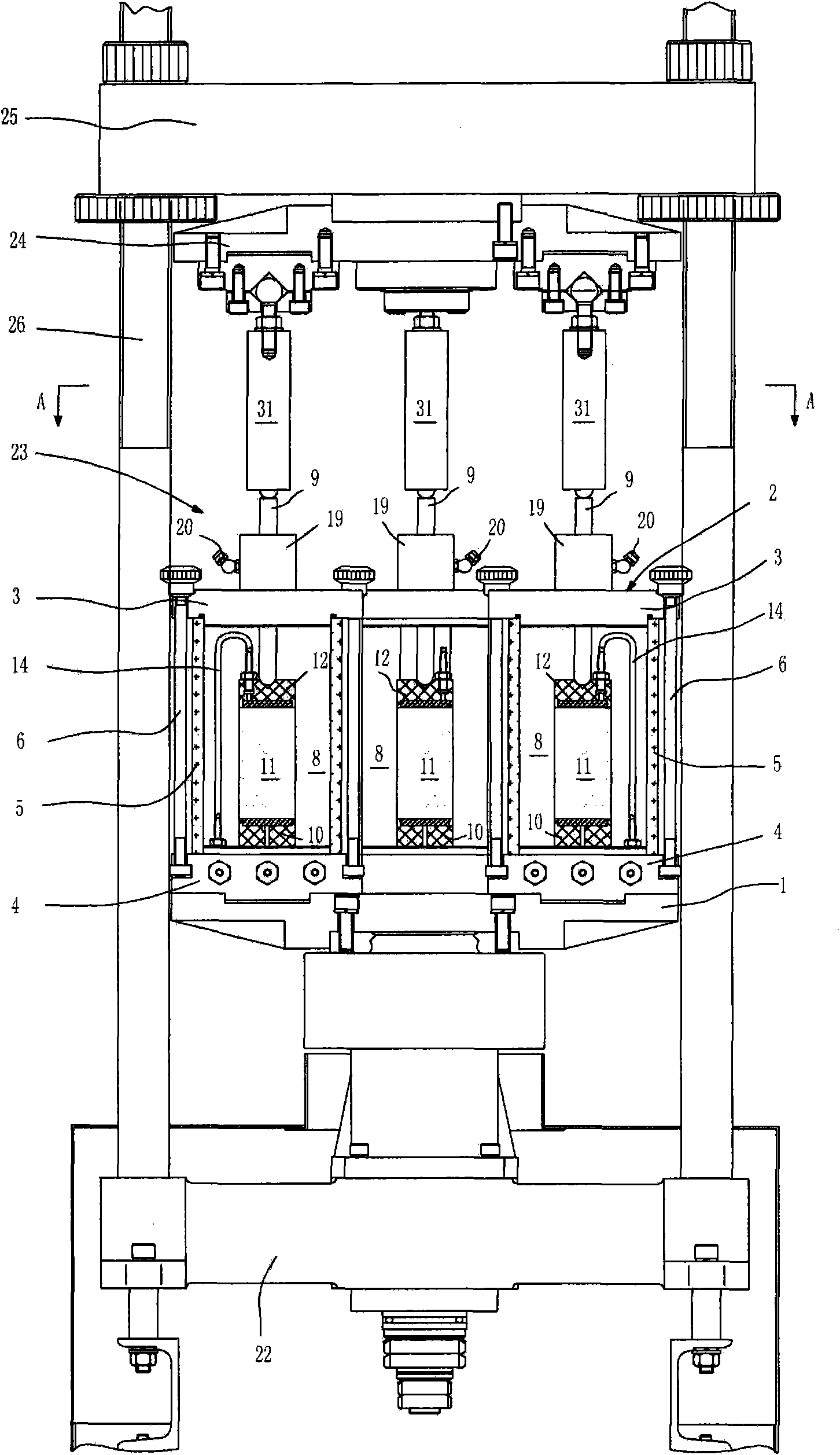

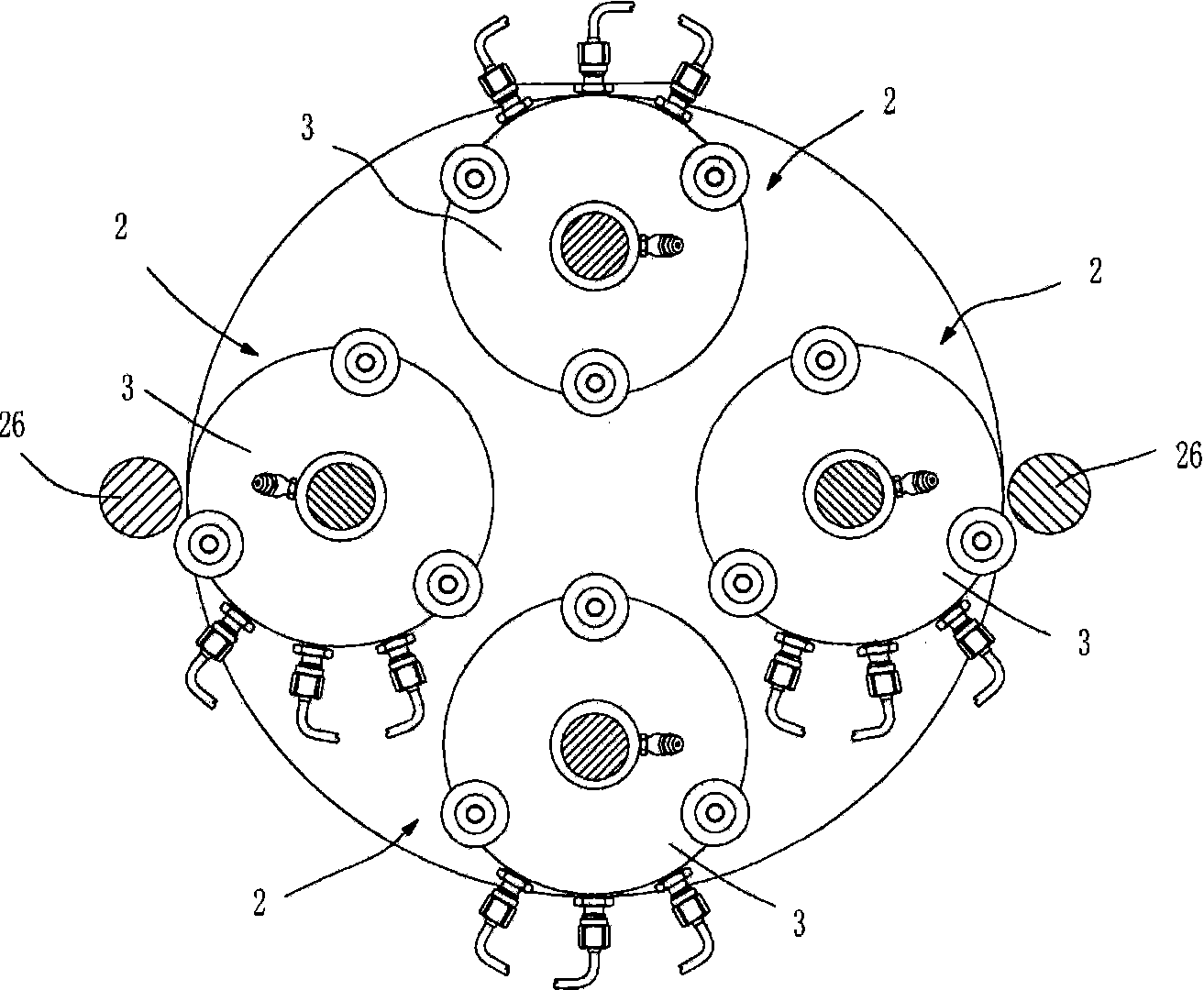

[0022] Such as figure 1 As shown, the improved triaxial instrument is provided with an axial pressurizing device 22 , a jacking platform 1 , a triaxial pressure chamber platform 23 , a reaction force platform 24 , and an upper beam 25 in sequence from bottom to top. The axial pressing device 22 and the upper beam 25 are fixed to each other by means of supports 26 . Such as figure 2 As shown, four pressure chamber units 2 are evenly arranged in the three-axis pressure chamber platform 23 .

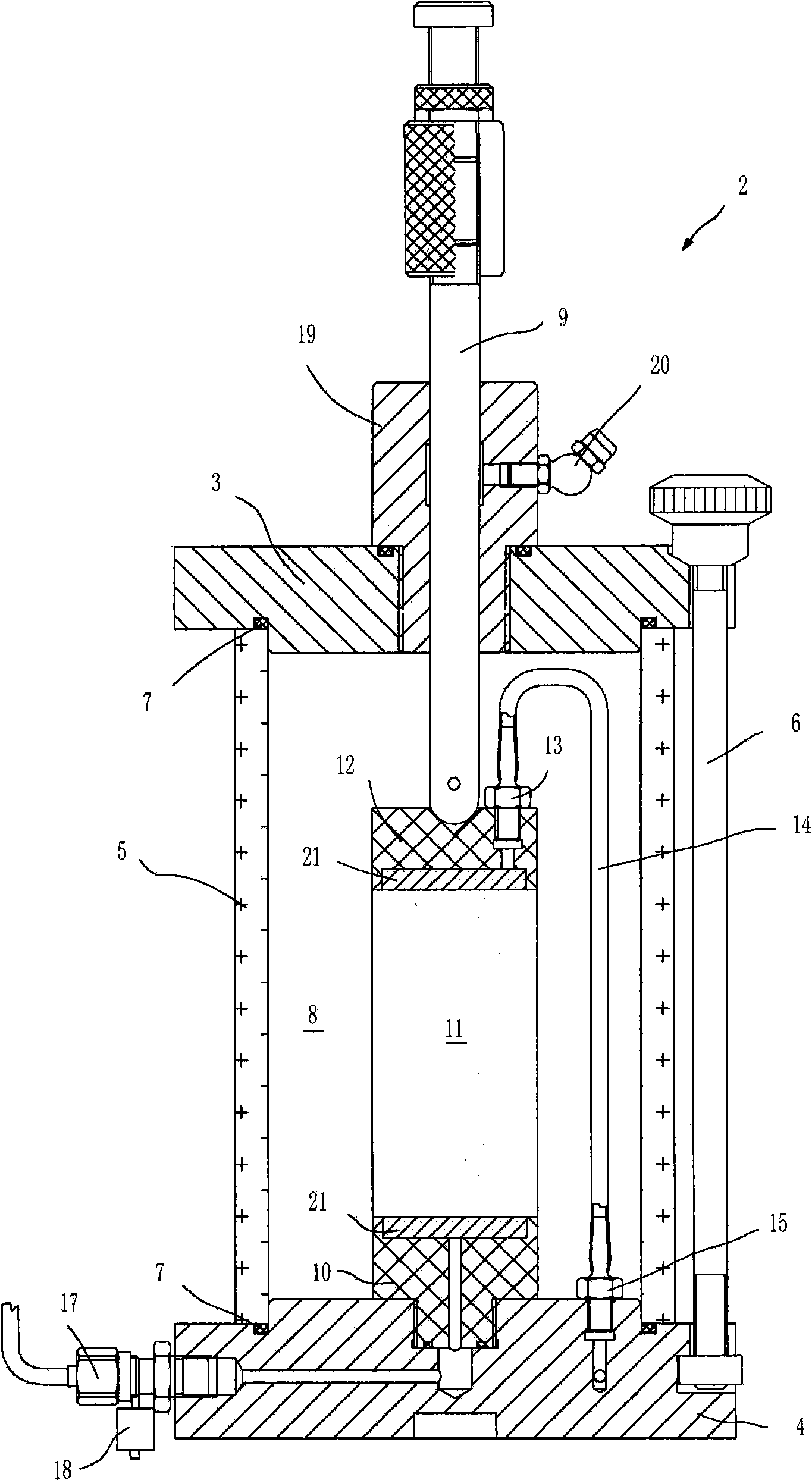

[0023] Such as image 3 As shown, each pressure chamber unit 2 includes a top cover 3 , a base 4 for placing a sample, and a pressure cylinder 5 . The top cover 3 , the base 4 and the pressure cylinder 5 form a closed space 8 . Such as image 3 , Figure 4 As shown, the edges of the top cover 3 and the base 4 are compressed by three pull rods 6, and O-rings 7 are arranged between the pressure cylinder 5, the top cover 3, and the base 4 to keep the closed space 8 sealed. The piston 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com