Solar battery module and method for manufacturing the same

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of installation space restrictions, cost increases, etc., achieve simple manufacturing processes, stable series connection status, and low manufacturing unit price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

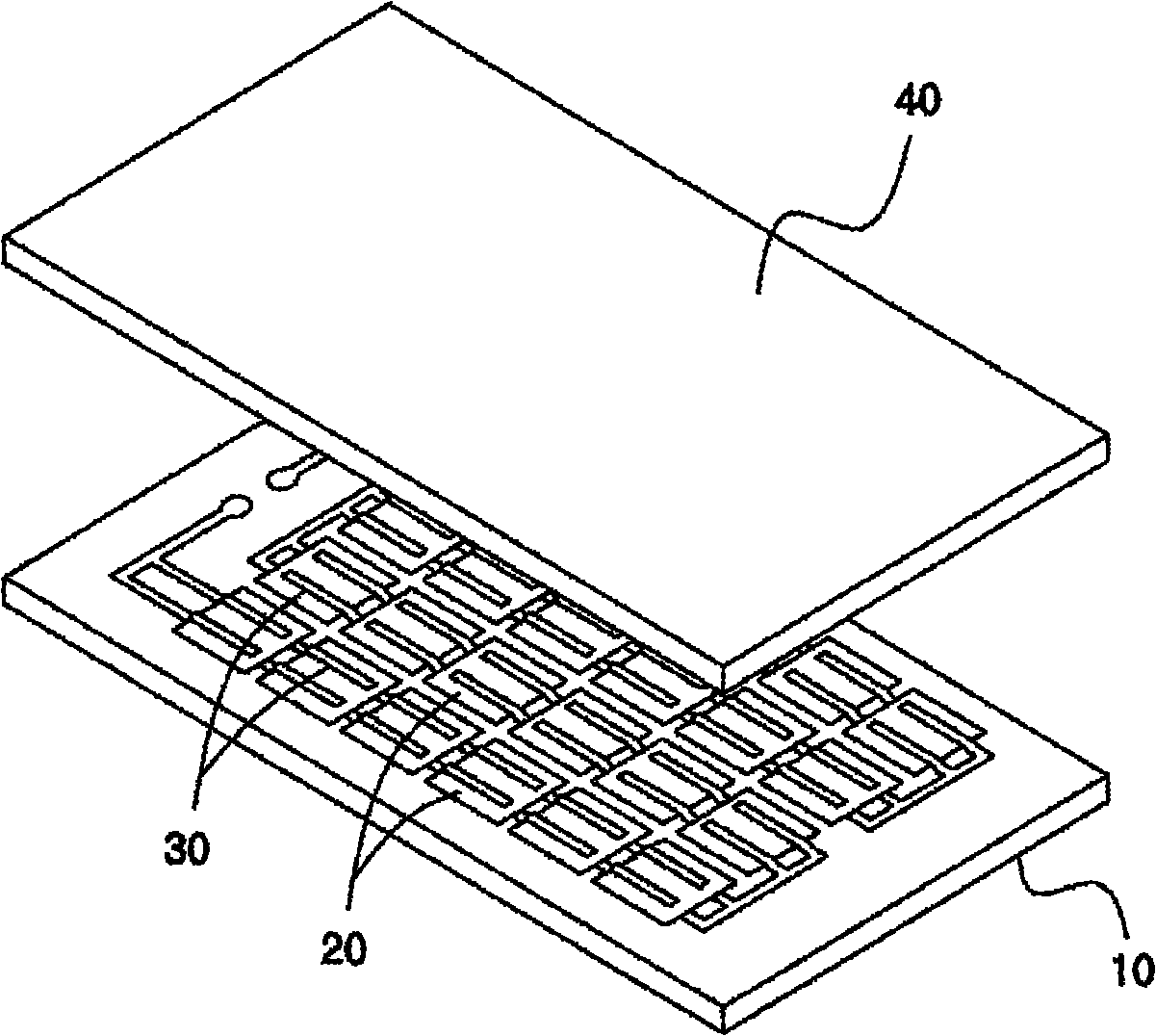

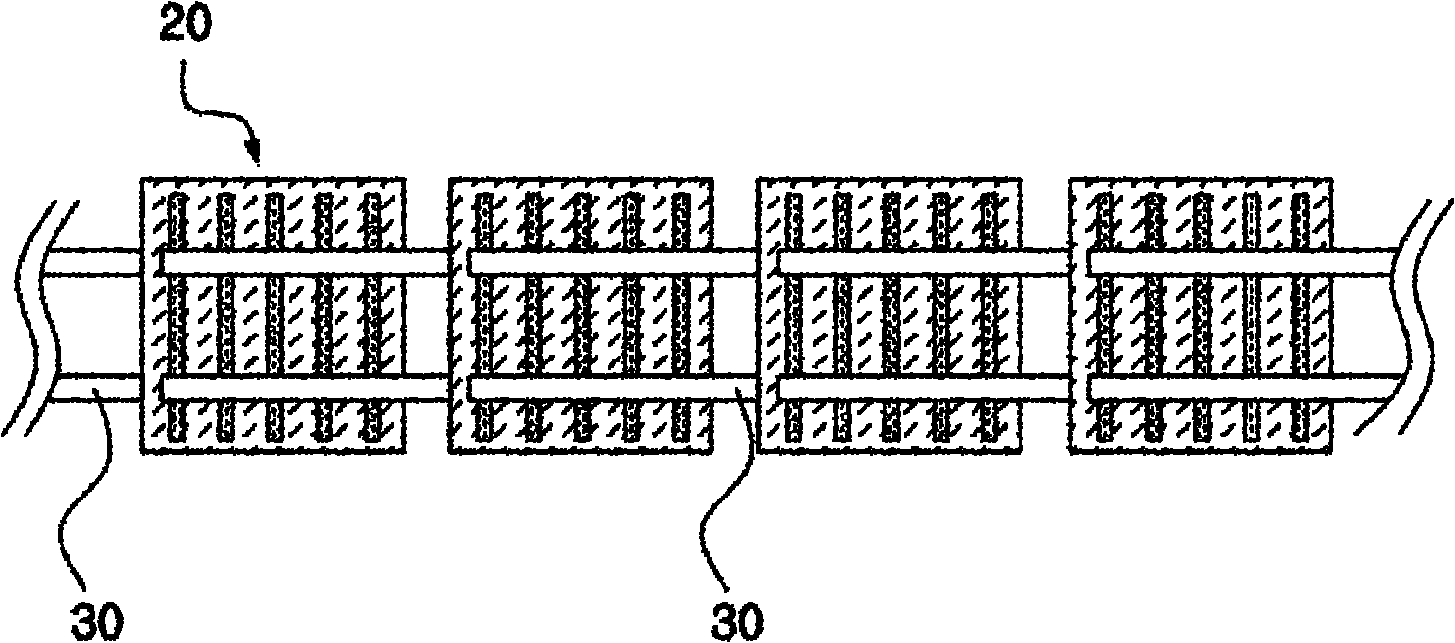

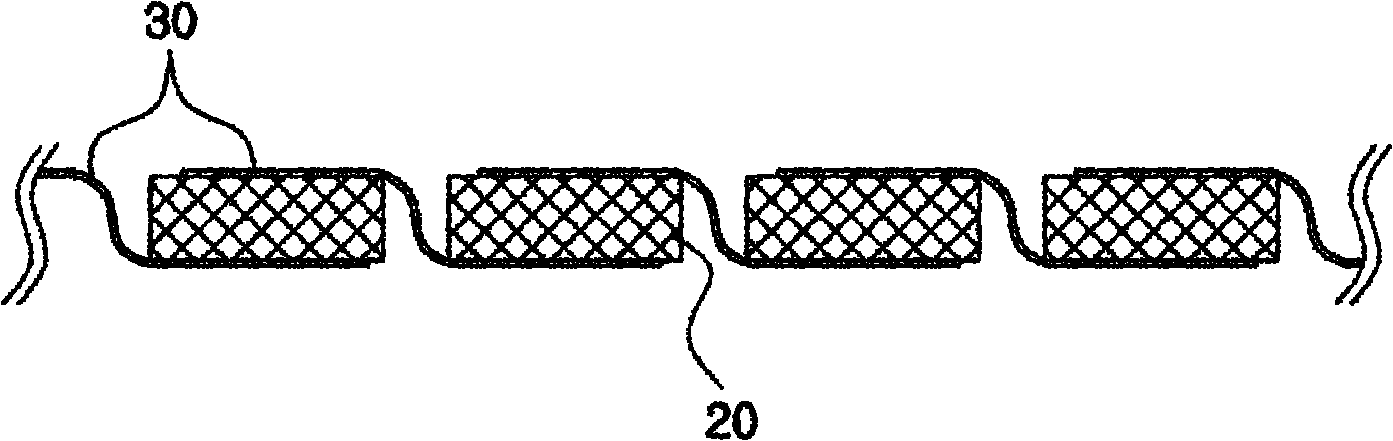

[0046] The above object of the present invention is achieved by the following solar cell module, that is, the solar cell module formed by connecting solar cells in series includes: a plurality of solar cells arranged in rows and columns; and a conductive strip electrically connecting the above-mentioned plurality of solar cells. The solar cell is a stacked structure of a first photovoltaic element composed of a polycrystalline semiconductor layer and a second photovoltaic element composed of an amorphous semiconductor layer.

[0047] The above-mentioned solar cell may include: a substrate of conductive material; a first photoelectric element, including a first polycrystalline semiconductor layer formed on the above-mentioned substrate, a second polycrystalline semiconductor layer formed on the first polycrystalline semiconductor layer, and a The third polycrystalline semiconductor layer on the above-mentioned second polycrystalline semiconductor layer; the second photoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com