Hub generator for bicycle

A technology for hub generators and bicycles, which is applied to synchronous generators, bicycle accessories, synchronous motors with stationary armatures and rotating magnets, etc. It can solve the problems of stable shape and dimension accuracy of stator cores or cylindrical cores, and achieve the best shape Dimensional accuracy stabilization, eddy current loss suppression, eddy current suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

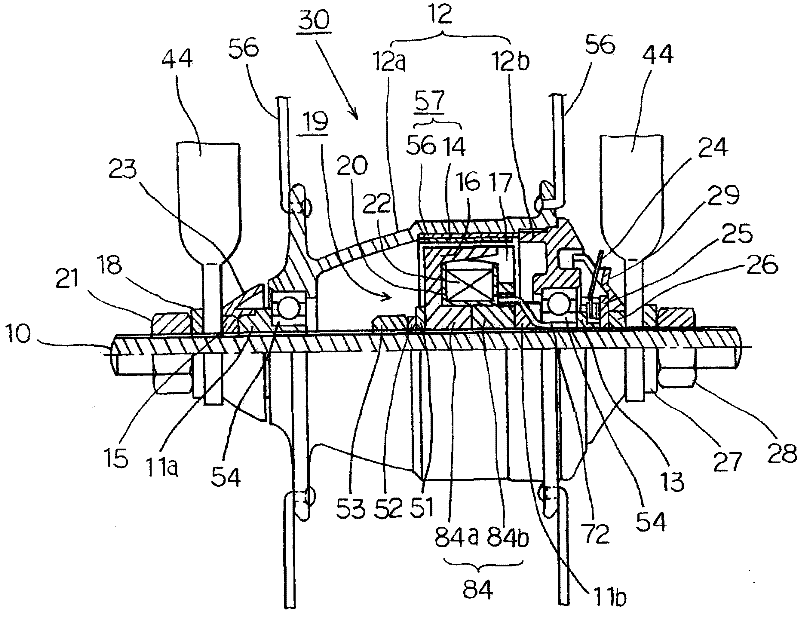

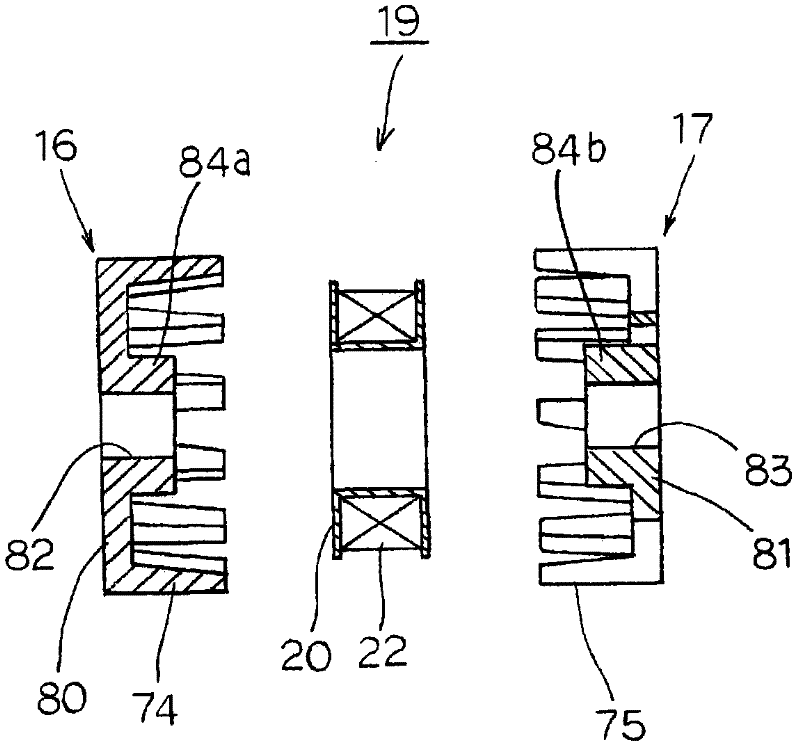

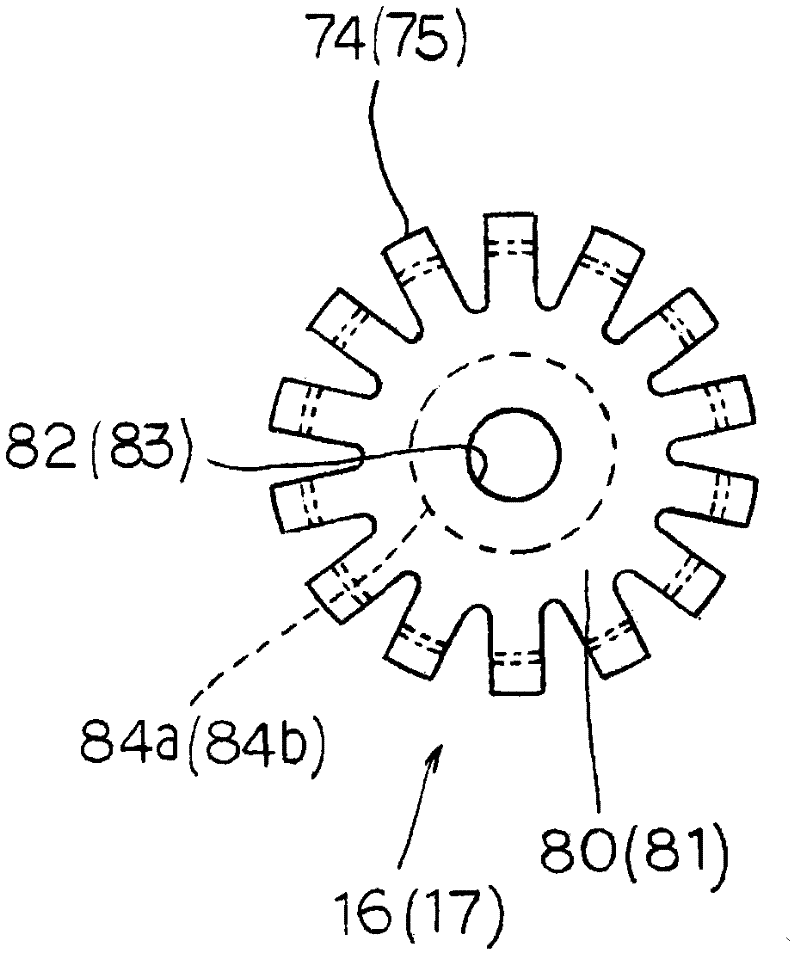

[0036] figure 1 It is a sectional view of one side (upper part) including the hub axis direction of the hub generator 30 of the present invention, figure 2 is an exploded front sectional view of the stator 19, image 3 is a side view of the stator core 16, 17, Figure 4 is an enlarged perspective view of the main part of the stator 19, Figure 5 An enlarged view showing a front wheel portion of a bicycle 40 on which the hub dynamo 30 is mounted.

[0037] The hub dynamo 30 of the present invention is mounted on the front wheel portion or the rear wheel portion of the bicycle 40 . Hereinafter, an example in which the hub dynamo 30 is mounted on the front wheel side will be described.

[0038] Such as Figure 5 As shown, in the bicycle 40, the hub axle 10 that supports the front wheel 42 so as to be rotatable is mounted on the front fork 44, and the hub dynamo 30 is arranged toward the headlight 46 arranged on the lateral side of the front wheel 42 or arranged on the rear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com