Chlorine introducing method and device for producing stannous chloride by liquid chlorine

A technology of stannous chloride and liquid chlorine, which is applied in the direction of stannous chloride and tin halide, can solve the problems of many safety hazards, large storage capacity of liquid chlorine, and slow gasification speed of liquid chlorine, achieving remarkable environmental benefits and accelerating Vaporization rate, effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

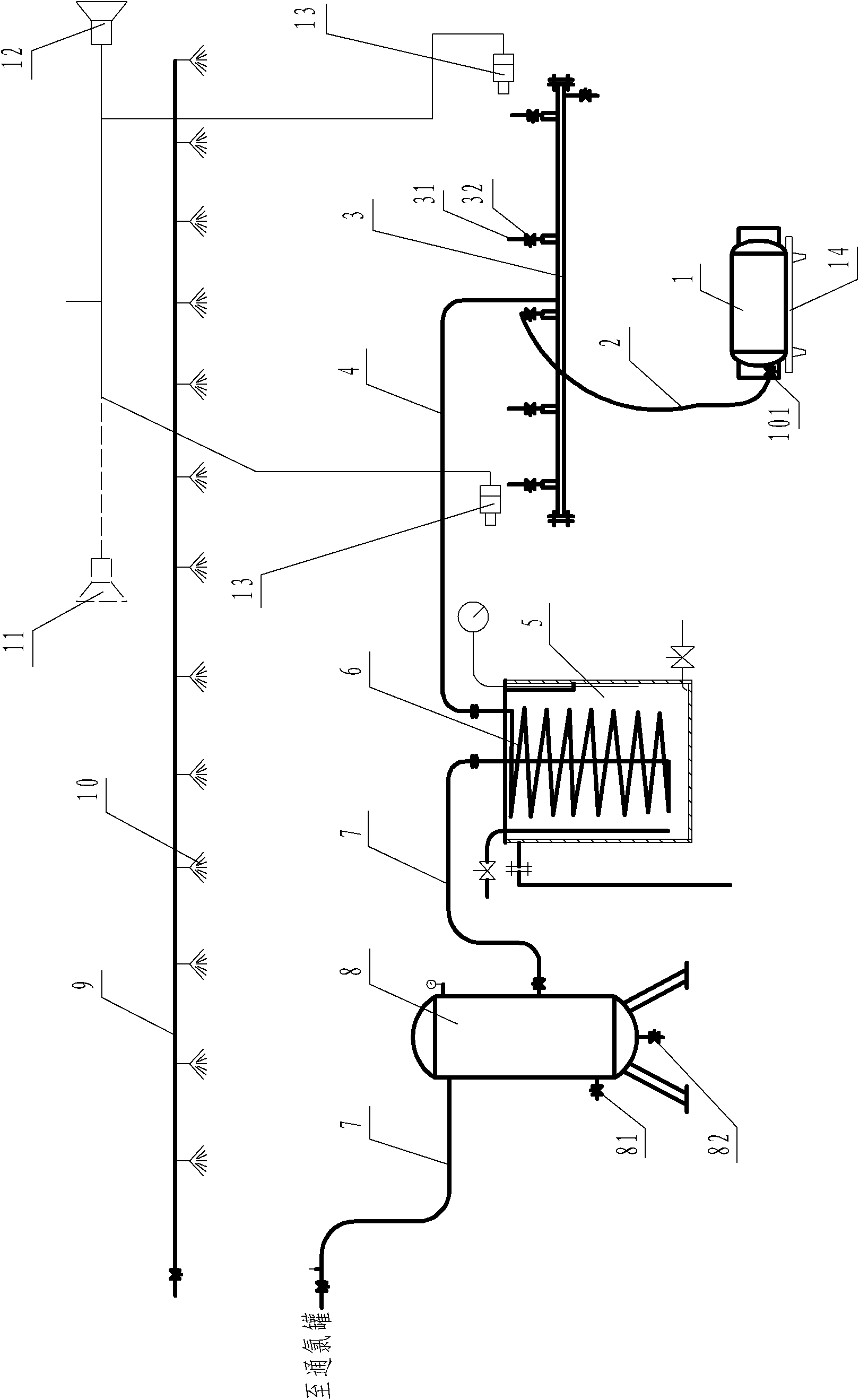

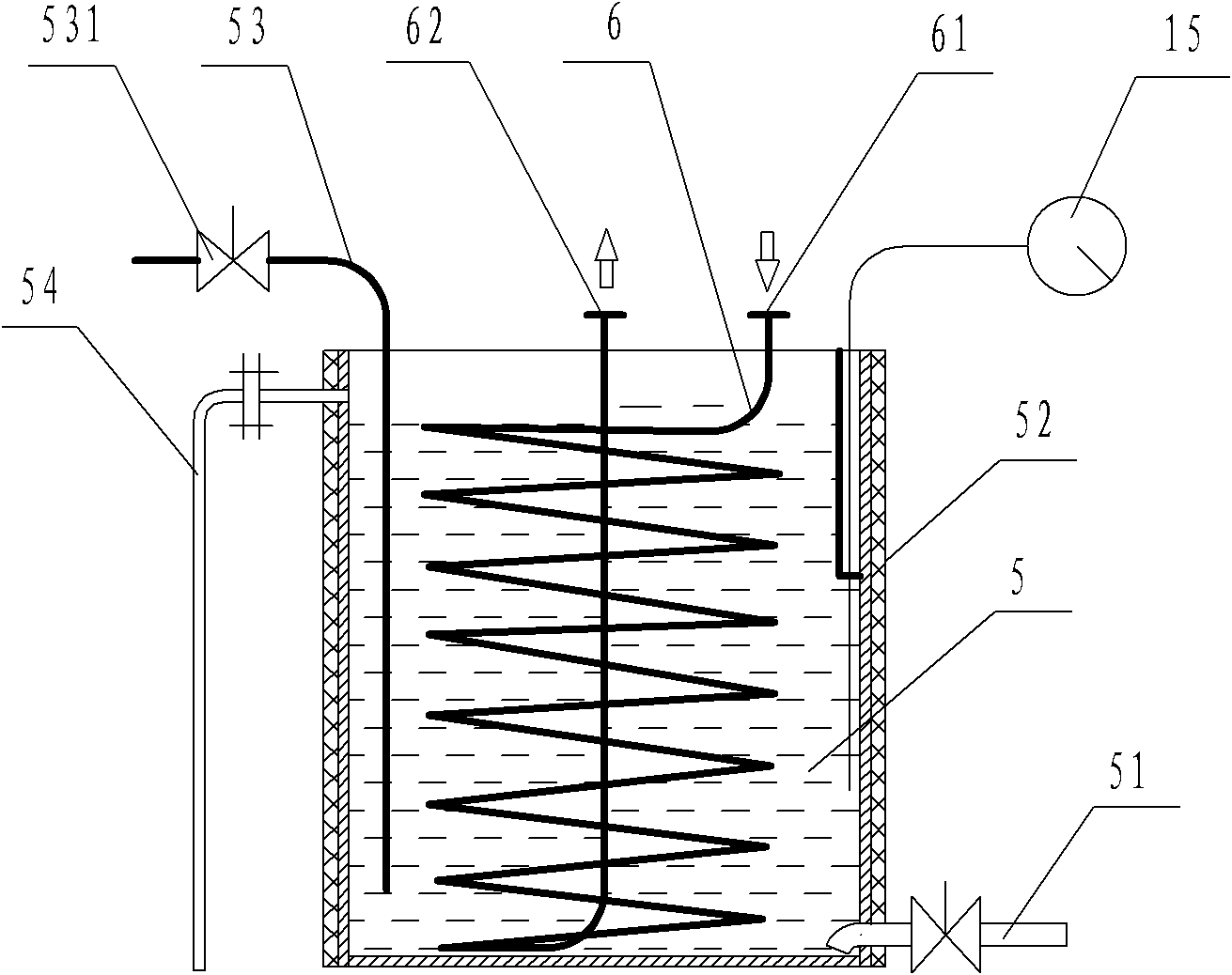

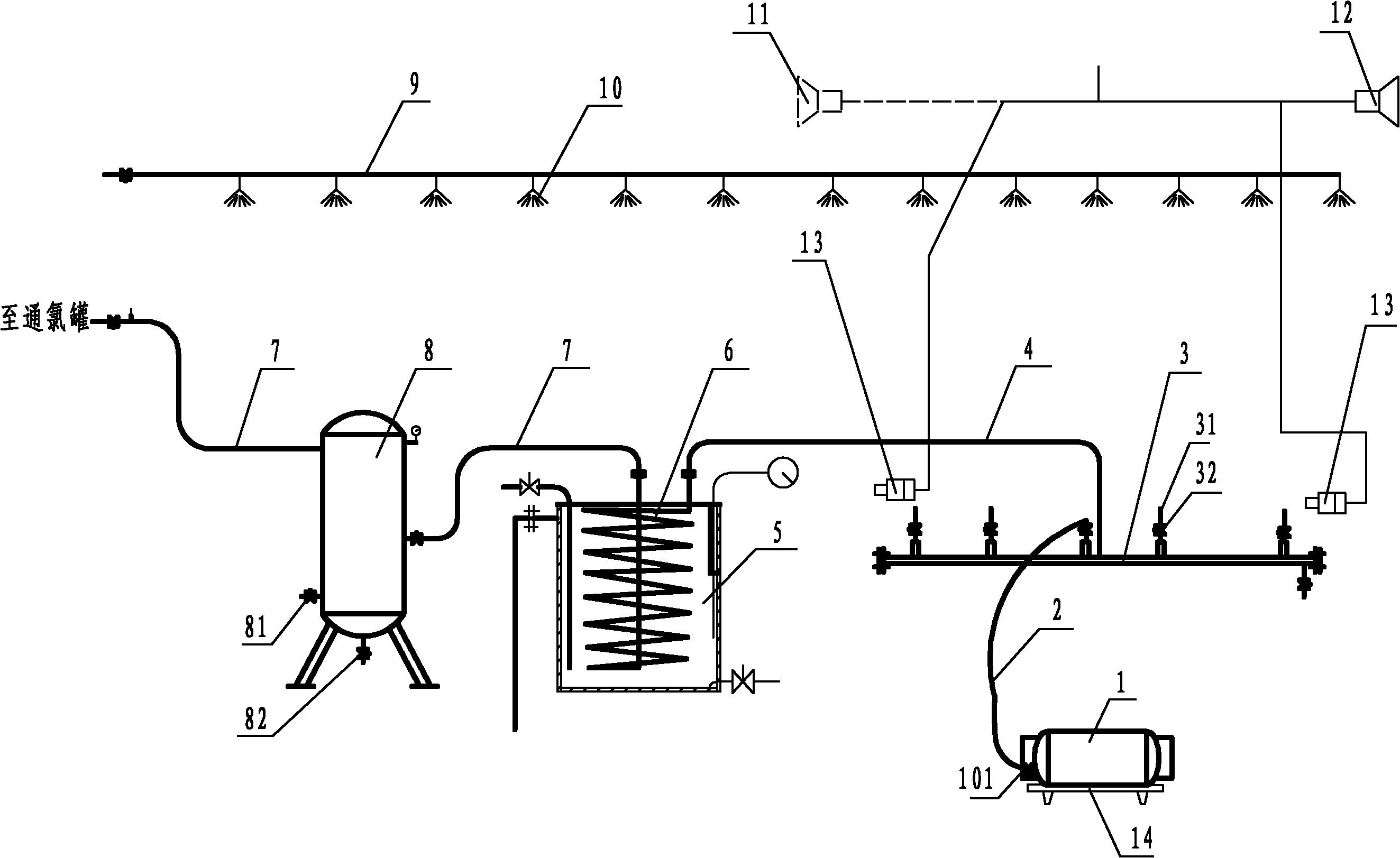

[0021] Embodiment 1: a kind of chlorine passing device that adopts liquid chlorine to produce tin protochloride (referring to Figure 1 ~ Figure 2 ), including liquid chlorine bottle 1, coil pipe 6, heating water tank 5 and chlorine buffer tank 8, liquid chlorine bottle is placed on metering scale 14, steam pipe 53 is passed into the heating water tank, and the outer surface of heating water tank 5 is arranged There is an insulating layer 52, the bottom of the heating water tank 5 is provided with a blowdown pipe 51, and the top is provided with an overflow pipe 54. The device is also provided with a liquid collecting pipe 3, five connecting pipes 31 provided with angle valves 32 are installed on the collecting pipe, and the coil inlet 61 communicates with the liquid chlorine bottle 1 through the liquid collecting pipe, that is, the liquid chlorine bottle 1 communicates with one of the connecting pipes 31 on the liquid collection pipe through the copper pipe 2, and the liquid ...

Embodiment 2~ Embodiment 6

[0024] Embodiment 2~Example 6: adopt the method for passing chlorine through the chlorine device described in embodiment 1, in the working process, liquid chlorine flows into the coil under the action of high pressure in the steel cylinder, and is heated by the hot water outside the coil , to accelerate its gasification, the specific parameters of the process of passing chlorine are as follows.

Embodiment 2

[0025] Example 2: Use a bottle of liquid chlorine bottle (one ton / bottle) filled with liquid chlorine to pass chlorine, the initial pressure of the chlorine buffer tank is 0.002Mpa, open the liquid chlorine bottle to start chlorine flow, control the heating water temperature at about 45°C, and control the buffer Pressure in the tank was 0.12Mpa, and after 6 hours and 50 minutes, the liquid chlorine in the liquid chlorine bottle basically flowed out, and the valve of the liquid chlorine bottle was closed, and the next liquid chlorine bottle was connected to continue chlorine feeding until the chlorination reaction ended.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com