Tow guide roller and application thereof

A wire guide and lining technology, applied in the field of tow guide rollers, can solve problems such as inability to ensure flexible rotation, failure to meet long-term high-load operation guidance needs, and weak bonding force of electrochemically coated ceramic layers. It is not easy to achieve The effect of napping, reducing flying flowers and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

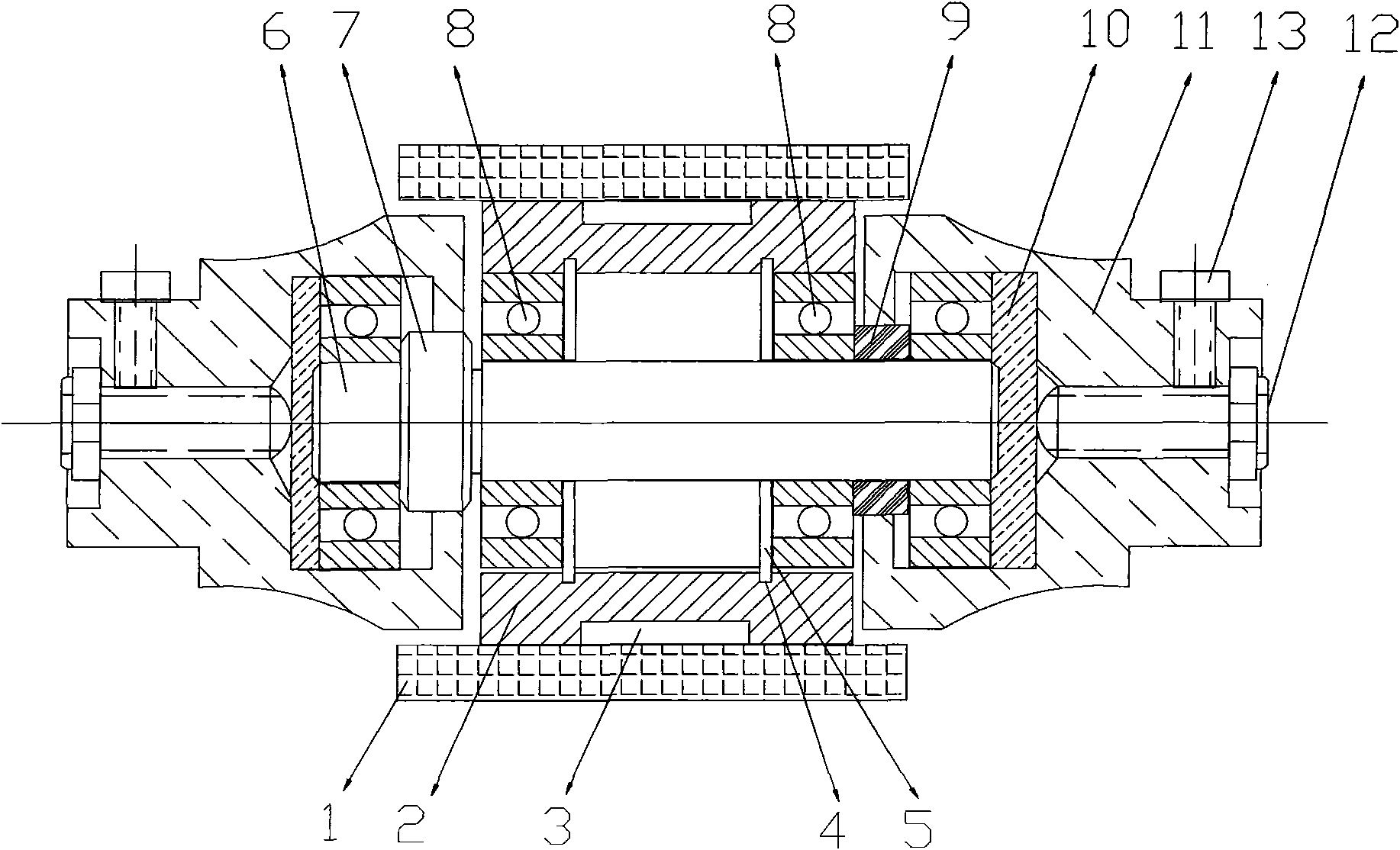

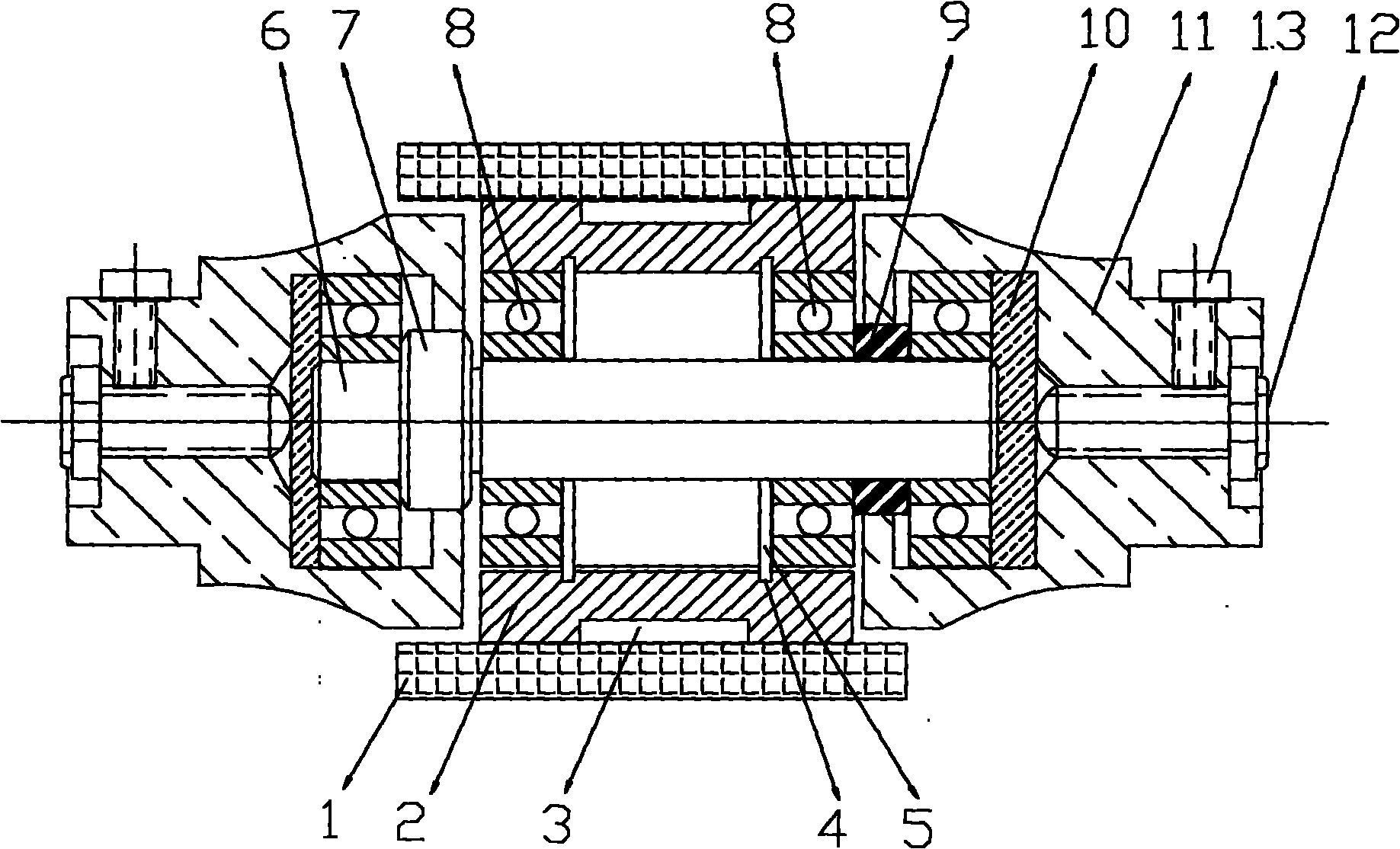

[0024] Among the above parts, choose: a full ceramic tube guide wire housing 1 with an outer diameter of 40mm and a wall thickness of 4mm. The ceramic tube contains aluminum oxide, and its content is 30%; the other selected inner lining 2 is made of steel The outer diameter of the shaft 6 containing the step 7 at one end is 10 mm, and two bearing groups 8 containing 2 bearings respectively.

Embodiment 2

[0026] Among the above components, select: a full ceramic tube guide wire housing 1 with an outer diameter of 50 mm and a wall thickness of 6 mm. The ceramic tube contains aluminum oxide, and its content is 35%; the other selected inner liner 2 is aluminum alloy Material, the outer diameter of the shaft 6 with the step 7 at one end is 12 mm, and two bearing groups 8 with 2 bearings respectively.

Embodiment 3

[0028] Among the above-mentioned components, choose: an enamel metal tube guide wire housing 1 with an outer diameter of 60mm, a wall thickness of 2mm, and an enamel thickness of 0.5mm. The enamel contains aluminum oxide, and its content is ≥ 30%; another selected The lining 2 is made of steel alloy, the outer diameter of the shaft 6 with the step 7 at one end is 14mm, and two bearing groups 8 with 2 bearings respectively.

[0029] The present invention is obtained by connecting each component in the above-mentioned 3 embodiments according to the structure shown in the accompanying drawings. When the present invention is used in the production line of cellulose acetate tow, the wire guide shell 1, the inner lining 2 and the bearing shell will rotate together to realize the traction and guiding functions of the cellulose acetate tow. Moreover, the flying of the tow is reduced, and the quality of the tow is protected from being affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com