Semiconductor packaging process and die utilized in same

A packaging process and semiconductor technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and electrical solid-state devices, and can solve problems such as reducing yield and increasing efficiency and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

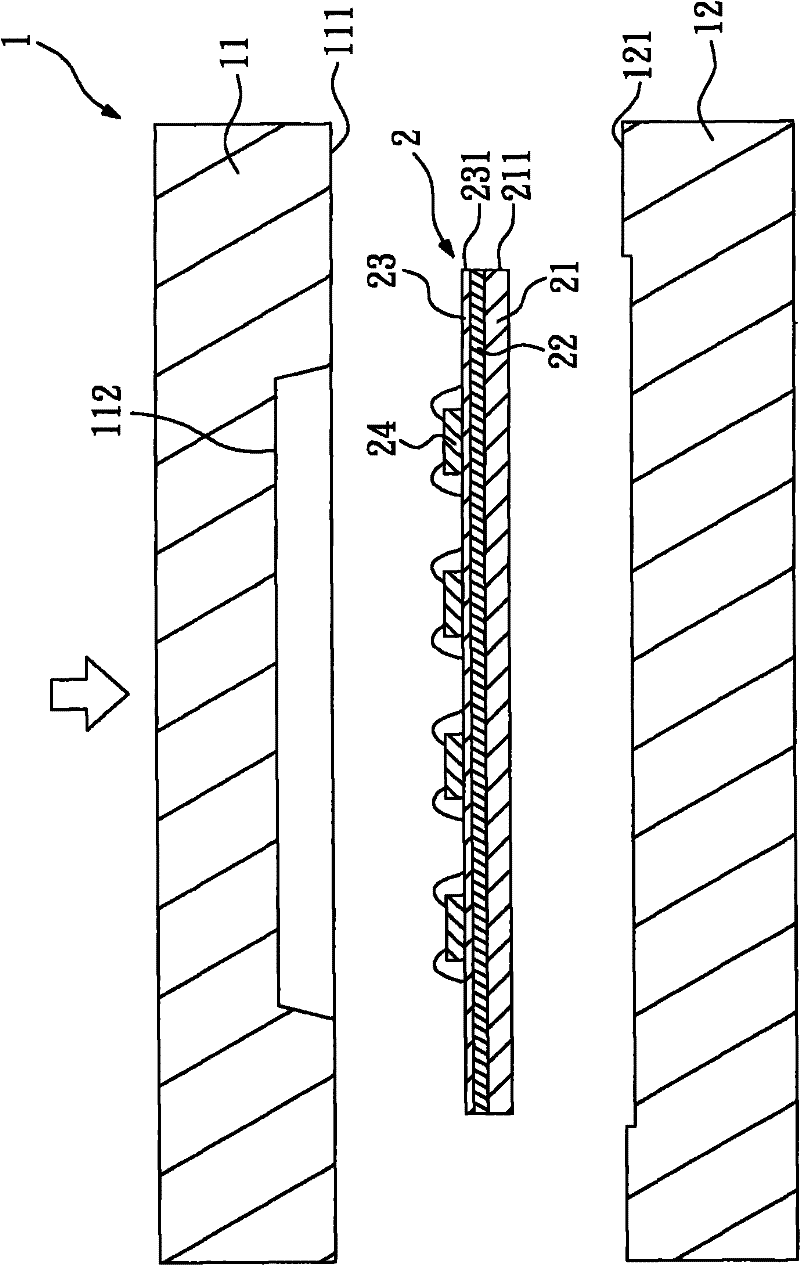

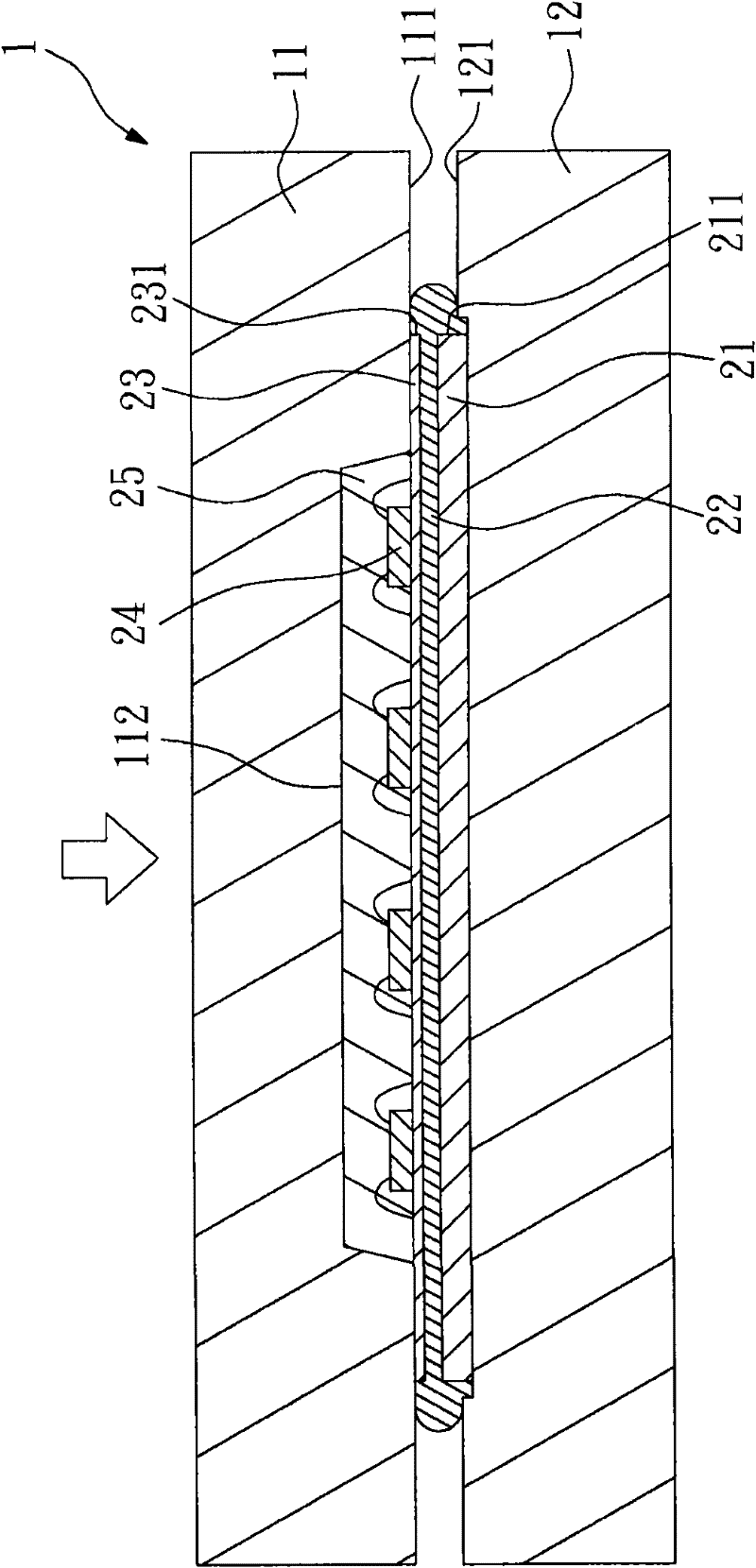

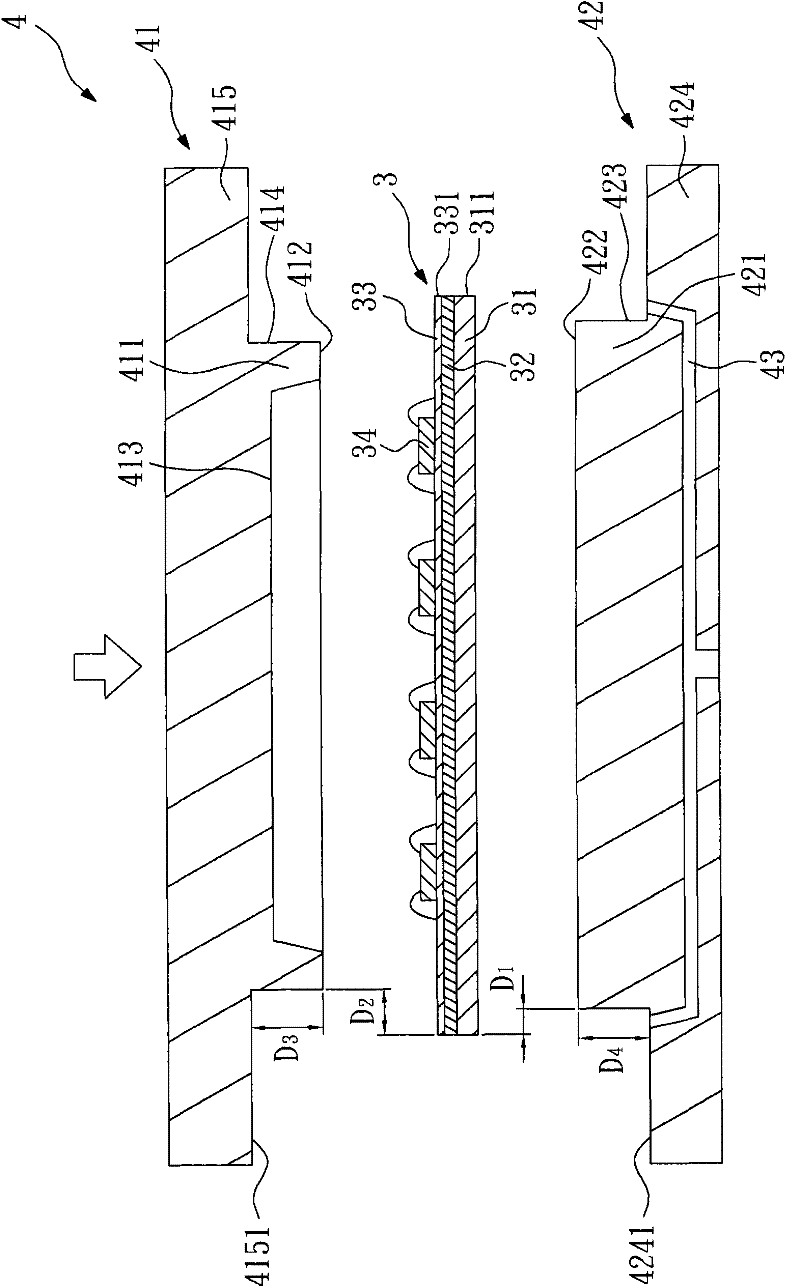

[0012] refer to Figure 3 to Figure 5 , showing a schematic diagram of the semiconductor packaging process of the present invention. refer to image 3 , provide a half finished product 3 and a mold 4 . The semi-finished product 3 includes a carrier 31 , an adhesive 32 , a semiconductor substrate 33 and at least one semiconductor component 34 , and the carrier 31 has a first outer peripheral surface 311 . The semiconductor substrate 33 is a wafer or an interposer, which has a second peripheral surface 331 , and is adhered to the carrier 31 by the adhesive 32 , so that the carrier 31 serves as a support for the semiconductor substrate 33 . The semiconductor component 34 is disposed on the semiconductor substrate 33 . The mold 4 includes an upper mold 41 and a lower mold 42, the upper mold 41 has a pressing portion 411, the pressing portion 411 has a pressing surface 412, at least one mold cavity 413 and a third outer peripheral surface 414, the The mold cavity 413 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com