Drift folded marsh gas collector

A biogas collector and biogas technology, applied in the field of biogas collection equipment, can solve the problems of long recovery time, burns, and poor air circulation, and achieve the effects of quick cost recovery, small investment, and reduction of danger and work difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

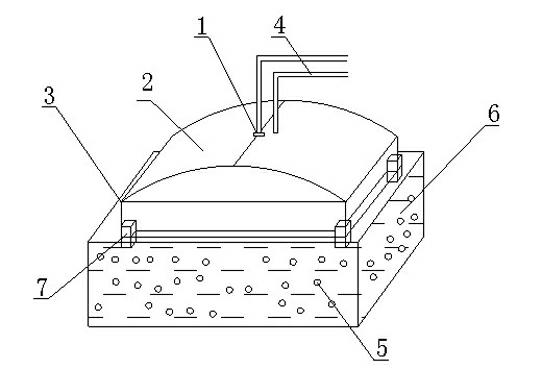

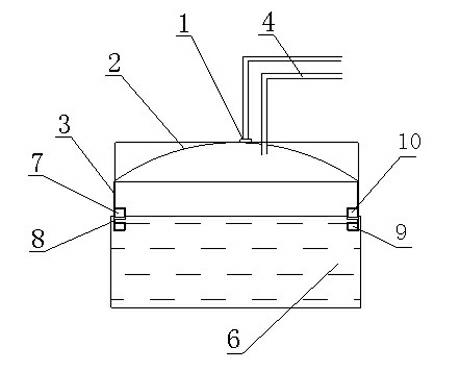

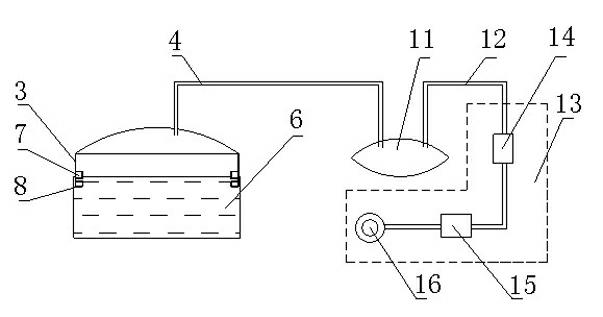

[0016] Such as figure 1 , figure 2 , a drifting folding biogas collector, which consists of a biogas probe 1, a suspension cover 2, a suspension cover support 3, a gas delivery pipe 4, and a floating device 7. The suspension cover support 3 floats in the fermentation tank 6, and the suspension cover 2 is installed on the suspension cover support. 3 to form an air chamber, and the bottom of the suspension cover support 3 is equipped with an array of floating devices 7. The floating device 7 is immersed in the fermentation liquid of the fermentation tank 6. The biogas probe 1 is located above the suspension cover 2 and is in contact with the suspension cover 2 when it is inflated. The air pipe 4 passes through the suspension cover 2 and communicates with the air chamber, the biogas probe 1 is connected to the compressor through the control circuit, and the load end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com