Method for measuring dryness of downhole steam in thermal recovery horizontal well

A measurement method and horizontal well technology, which is applied in the direction of measurement, wellbore/well components, production fluid, etc., can solve the problem that the dryness of steam cannot be tested, and achieve the effect of convenient application, high sensitivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

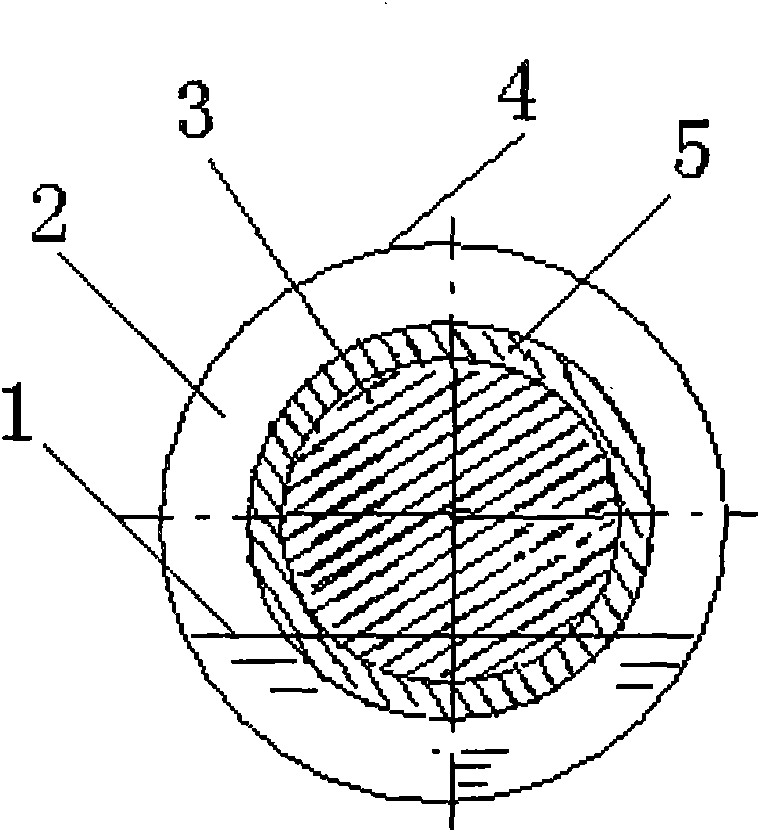

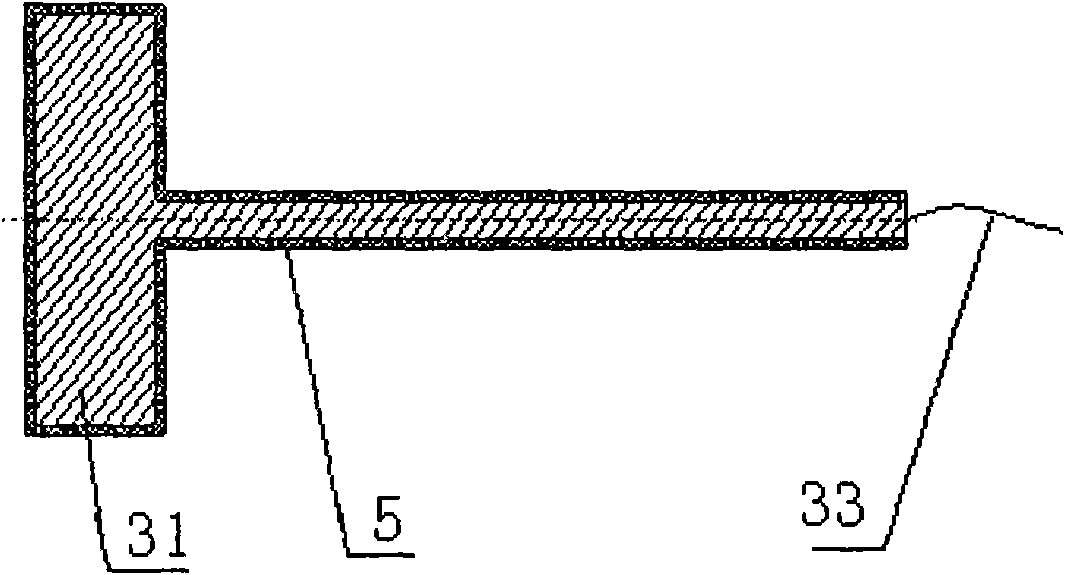

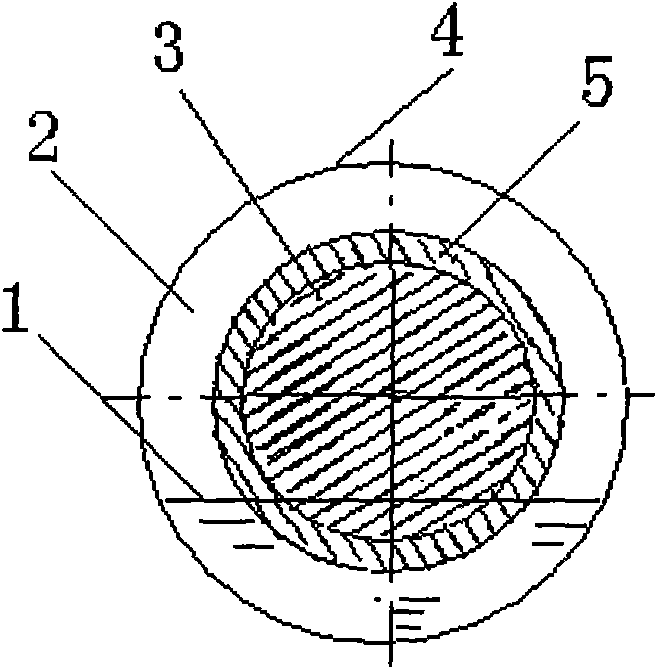

[0040] refer to Figure 1-Figure 2 , a method for measuring the dryness of downhole steam in a thermal recovery horizontal well, comprising using a two-phase mixed fluid 2 of steam and water in the horizontal section of the wellbore 4 of the thermal recovery horizontal well, a capacitance sensor and a capacitance probe 3 to form a capacitor, and measuring the thermal recovery horizontal well Steam dryness in the horizontal section of the wellbore. The water phase 1 in the two-phase mixed fluid 2 of steam and water, the capacitance sensor and the capacitance probe 3 form a circular capacitor, the water phase 1 is used as the negative pole of the circular capacitor, and the capacitance sensor and the capacitance probe 3 are used as the positive pole of the circular capacitor. The voltage is measured by the capacitive sensor, and the liquid level of the water phase is calculated. The relationship between the liquid level of the water phase 1 and the voltage is as follows: The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com