Shade-body external heat conduction and dissipation type full-power LED (Light Emitting Diode) lamp

A heat dissipation technology for LED lamps, which is applied in the field of full-power LED lamps with external conduction and heat dissipation. It can solve the problems of limited heat dissipation area and inability to meet the heat dissipation requirements of large-function LED lamps, so as to expand the irradiation range and facilitate popularization. The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, but the present invention is not limited in any way

[0017] system, any transformation made based on the teaching of the present invention, all fall within the protection scope of the present invention.

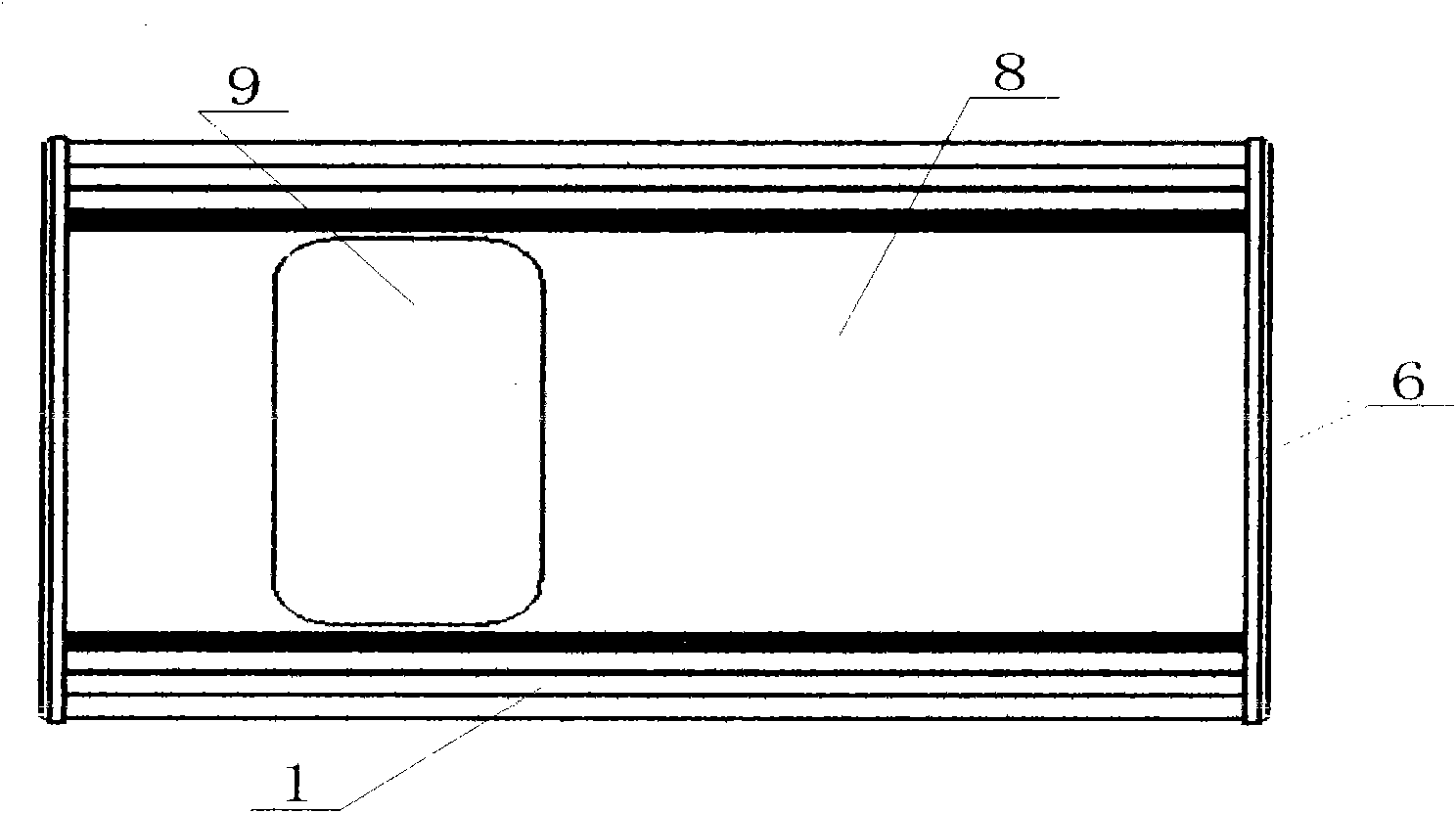

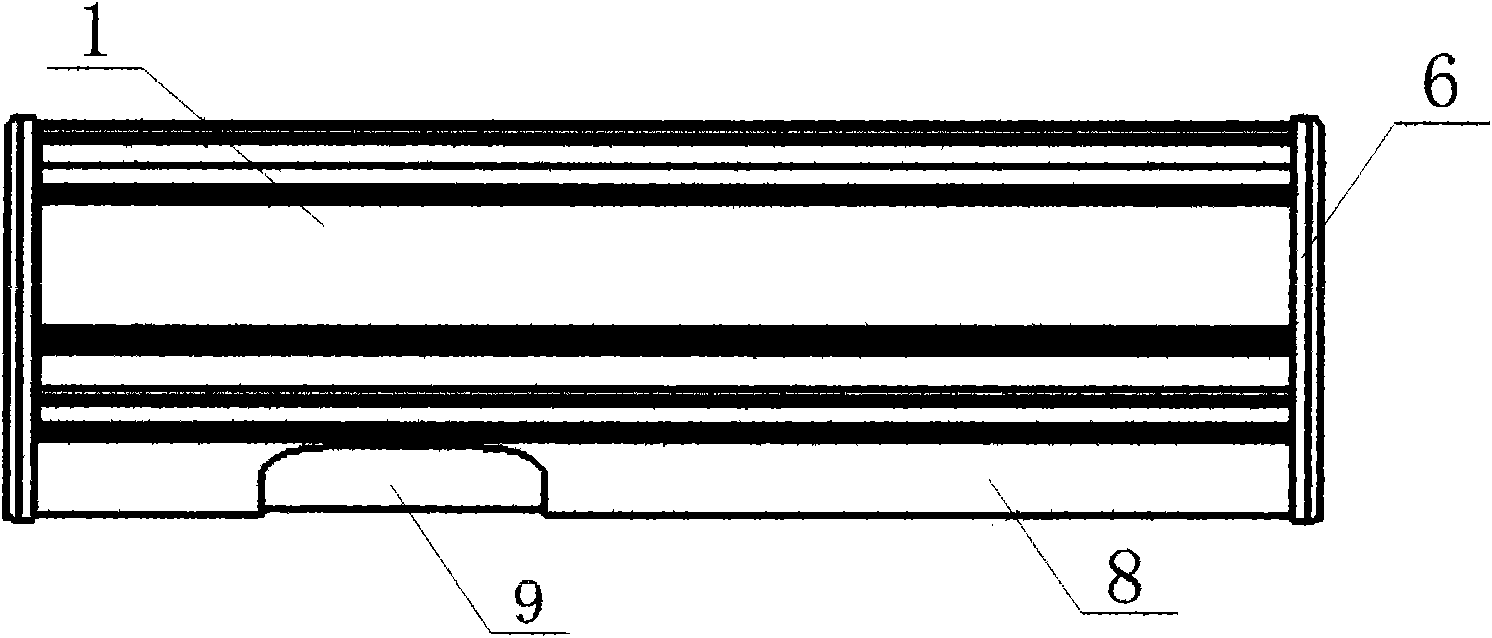

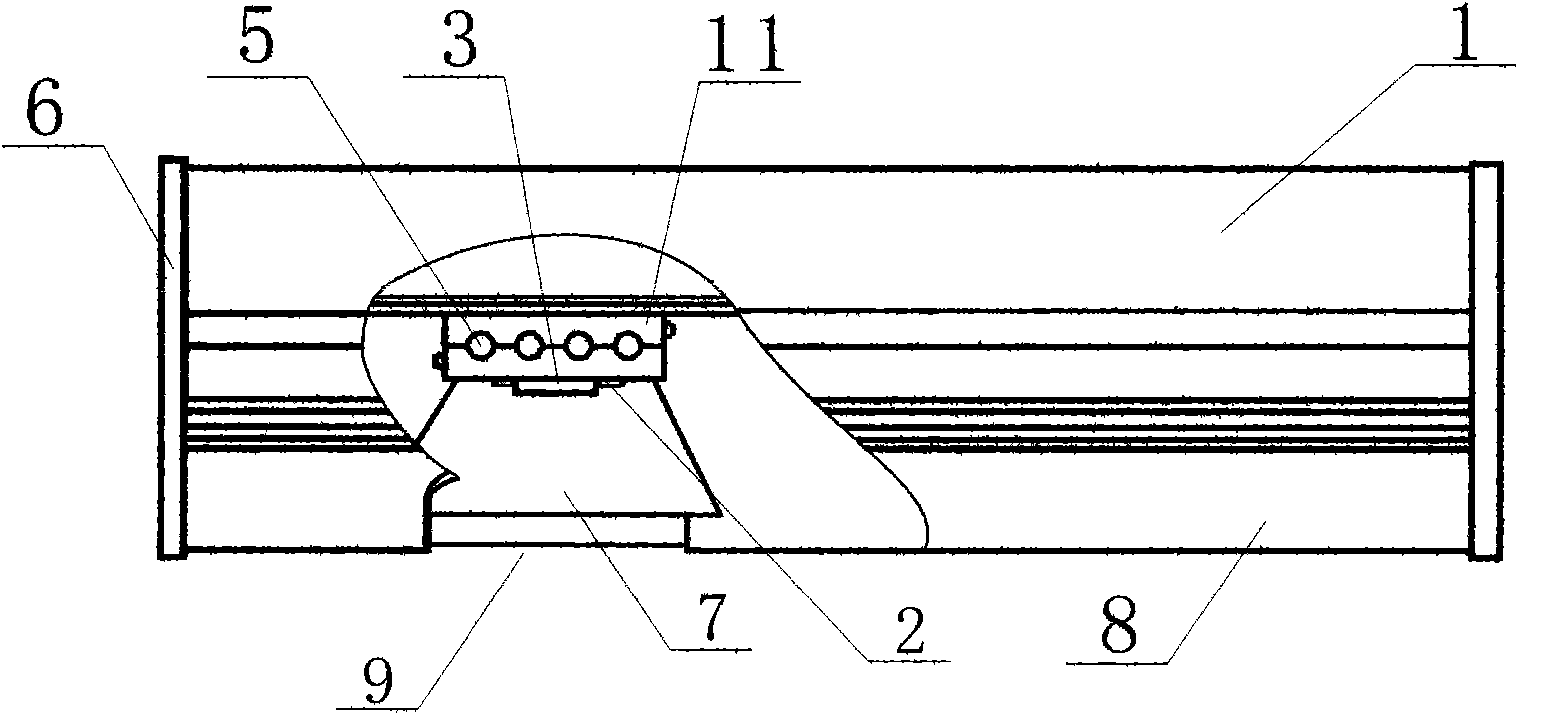

[0018] Such as Figure 1-Figure 6 As shown, the present invention includes a back cover 1, a heat collector 2, an LED light-emitting chip 3, an end cover 6, a concentrating tile 7, a front cover 8 and a light transmission cover 9, and the front cover 8 is provided with a light transmission cover 9 , the back cover 1 and the front cover 8 slide and buckle together and buckle with both ends of the cover to form a lamp cover. The heat collector 2 is arranged on the inner longitudinal axis of the back cover 1. The tile 7 is optically matched and arranged on the heat collector 2 , and the heat conduction fins 10 provided on the inner wall of the back cover 1 are thermally conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com