Gas and liquid two-phase flow uniform-distributing device and gas and liquid two-phase flow mixing method for plate-fin heat exchanger

A plate-fin heat exchanger, gas-liquid two-phase flow technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of increasing the length of the heat exchanger and fluid resistance, increasing the gas-liquid The size of the phase separation tank, the increase of fluid flow, etc., can achieve the effect of reducing the number of inlets and outlets, reducing fluid resistance, and reducing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

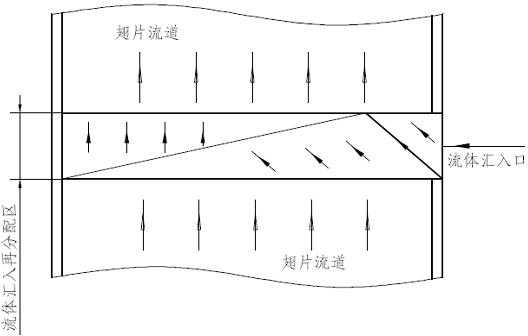

[0045] Such as Figure 4 to Figure 7As shown, a device for evenly distributing gas-liquid two-phase flow of a plate-fin heat exchanger. The interior of the plate-fin heat exchanger follows the direction of fluid flow, including fin flow channel I zone 8, liquid Distribution seal 7, fin flow channel II area 9, gas distribution seal 6, fin flow channel III area 10; the fin flow channel I area, fin flow channel II area, and fin flow channel III area are internal design There is a flow channel with heat exchange fins, the length of the liquid distribution seal, the length of the gas distribution seal and the width of the heat exchanger are consistent;

[0046] The liquid distribution seal and the gas distribution seal have a similar structure, including a fluid distribution seal 1 located between two partitions 2, the fluid in the fluid distribution seal 1 is liquid or gas, and the length of the fluid distribution seal is equal to The width of the heat exchanger is consistent, an...

Embodiment 2

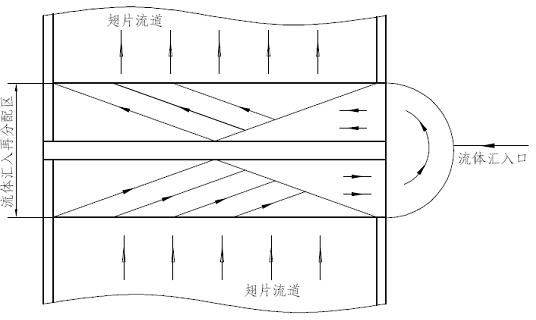

[0052] The structure of this device is basically the same as that of Embodiment 1, the difference is that two horizontal fluid channels 4 are arranged along the length direction of the fluid distribution seal, and the fluid channels 4 in the liquid distribution seal are connected with the fin flow channels. Zone I 8 communicates outside zone II of the fin channel, and the fluid channel 4 in the gas distribution seal communicates with zone II of the fin channel 9 outside zone III 10 of the fin channel.

[0053] At this time, the gas-liquid two-phase flow mixing method using the uniform distribution device of the plate-fin heat exchanger includes the following steps:

[0054] (1) The gas-liquid two-phase fluid to be imported is separated into liquid-phase fluid and gas-phase fluid after passing through the separation tank. The liquid-phase fluid enters the liquid distribution seal, and the fluid from the fin flow channel I area is in the liquid distribution seal. Mix evenly insi...

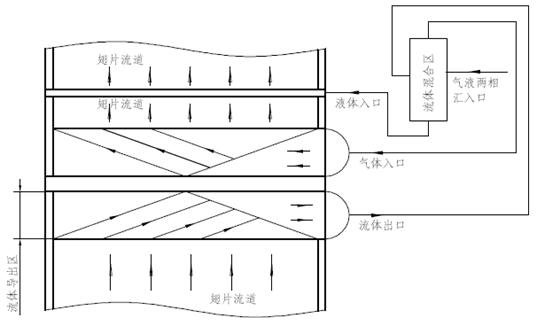

Embodiment 3

[0057] Such as Figure 8 , Figure 9 As shown, the structure of this device is basically the same as that of Embodiment 1, the difference is that the fluid distribution groove 3 and the fluid channel 5 are staggered, and the two are not on the same straight line parallel to the width of the fluid distribution seal.

[0058] The present invention is not limited to the above-mentioned embodiments, and can be extended to the reverse change of the fluid direction, the front and back sequence adjustment of the liquid distribution seal and the gas distribution seal, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com