Laminating method for solar battery component panel manufacturing process

A solar cell and underlying technology, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as high cost, huge equipment, and unclear positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

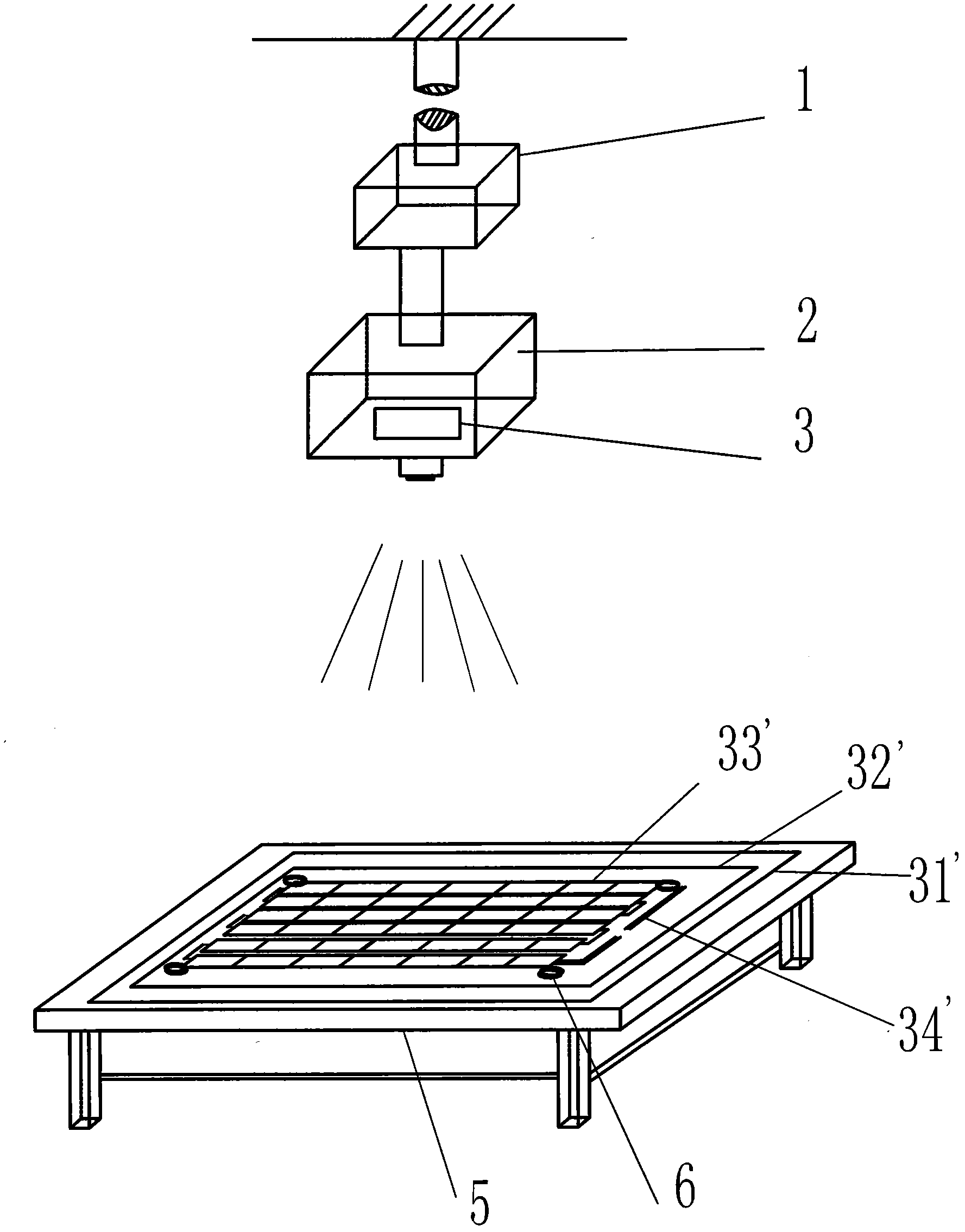

[0045] The embodiment of the present invention is used as figure 1 shown equipment Figure 5 The lamination of each layer of components in the shown solar cell module board, each layer of components is specifically:

[0046] ——The front top layer 1 is tempered glass;

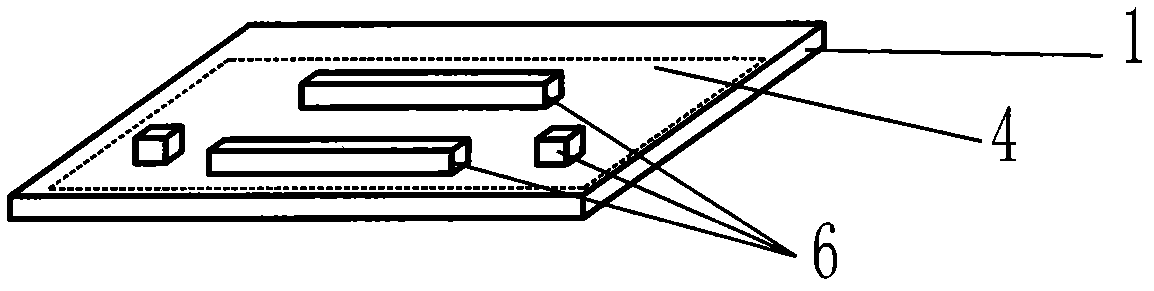

[0047] - Both the front top adhesive layer 2 and the back adhesive layer 4 are ethylene-vinyl acetate copolymer films;

[0048] ——The back layer 5 is TPT;

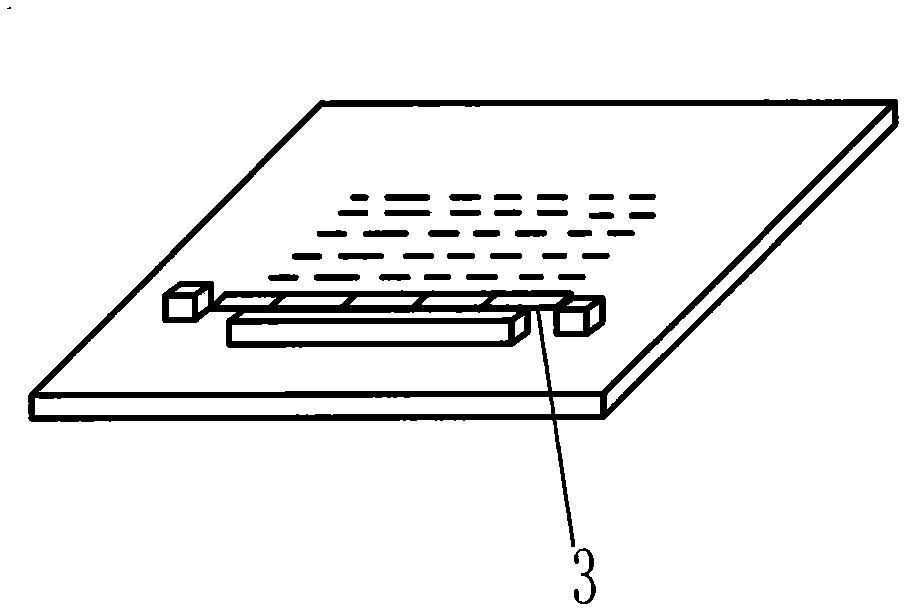

[0049] ——The solar cell string array 3 includes multiple strings of solar cells connected by soldering strips 16 as conductive strips.

[0050] Such as figure 1 The equipment shown: the suspension adjustment device 1 fixed on the ceiling of the workshop is designed as a 3-axis adjustment mechanism such as the workbench of CNC machining equipment, which can electrically adjust the slide projector 2 to the right above the workbench 5 according to the appropriate height and orientation, and its projection With your head facing straight down, the image of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com