Nonaqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte storage batteries, secondary batteries, batteries, etc., can solve problems such as battery explosion, and achieve the effect of improving high-temperature charging and storage characteristics and excellent safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

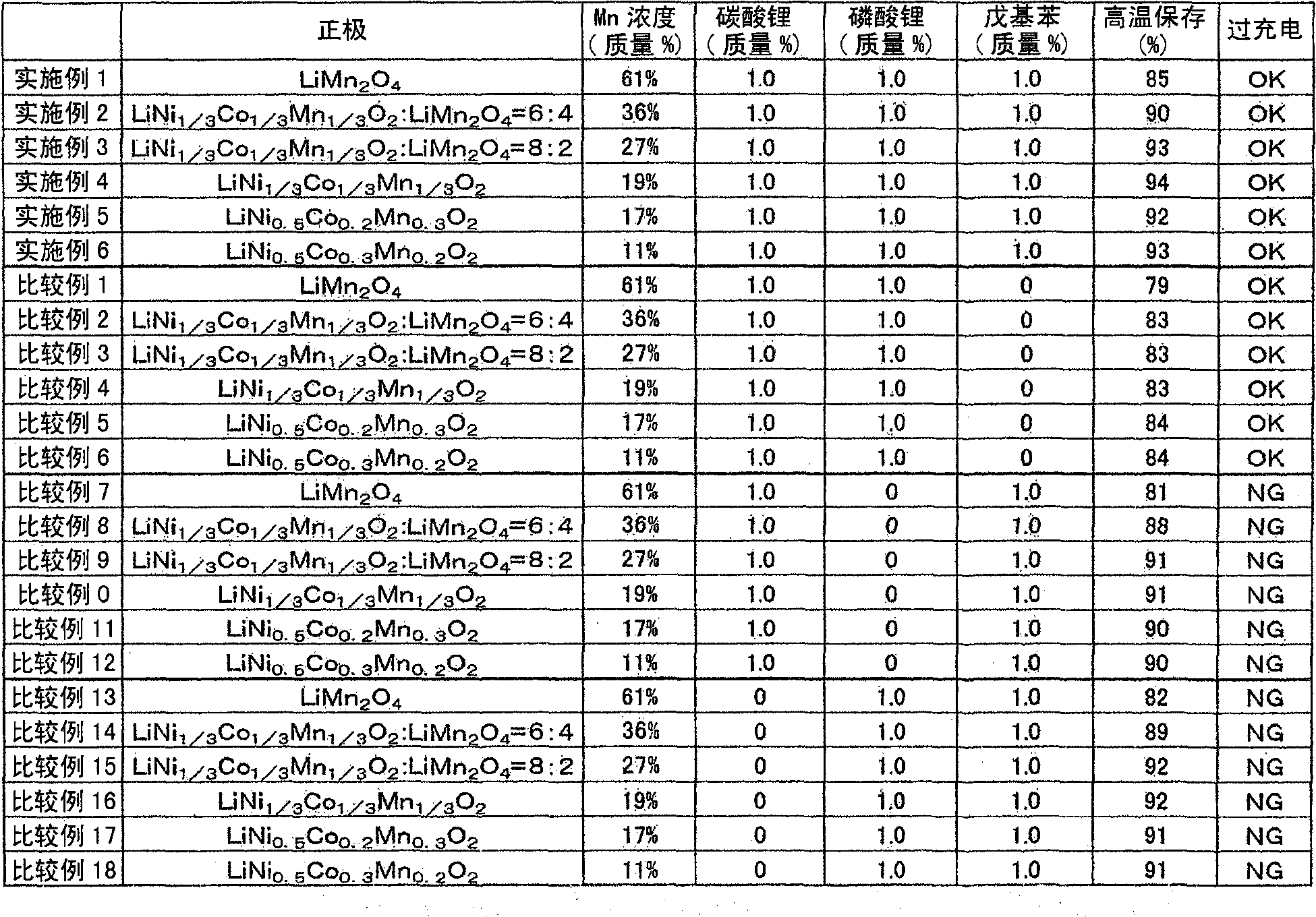

Embodiment 1~6

[0051] First, a specific manufacturing method of the non-aqueous secondary battery commonly used in Examples 1 to 6 will be described.

[0052] [Production of positive electrode plate]

[0053] First, carbonate is co-precipitated by adding sodium bicarbonate to an aqueous sulfate solution containing Ni, Co, Mn of various compositions as appropriate. Thereafter, a mixture of oxides as raw materials is obtained by subjecting these co-precipitated carbonates to a thermal decomposition reaction. Second, using lithium carbonate (Li 2 CO 3 ) as the initial raw material of the lithium source, the oxide mixture and lithium carbonate were mixed in a mortar, and the obtained mixture was fired in air to synthesize the specified lithium manganese composite oxide (LiMn 2 o 4 ) and fired bodies of lithium-containing nickel-cobalt-manganese composite oxides of various compositions.

[0054] Thereafter, the synthesized fired body was pulverized to an average particle diameter of 10 μm to...

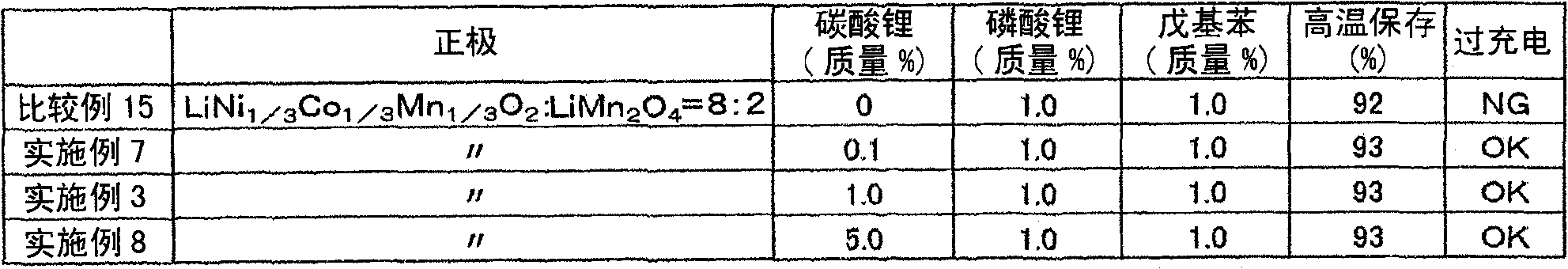

Embodiment 7 and 8

[0068] The battery of embodiment 7 and 8 uses LiNi identical with embodiment 3 1 / 3 co 1 / 3 mn 1 / 3 o 2 : LiMn 2 o 4 =8:2 As the positive active material, the content of the positive active material in the positive electrode mixture is set to 0.1 mass % (embodiment 7) or 5.0 mass % (embodiment 8), in addition, with embodiment 3 Batteries are similarly operated to make.

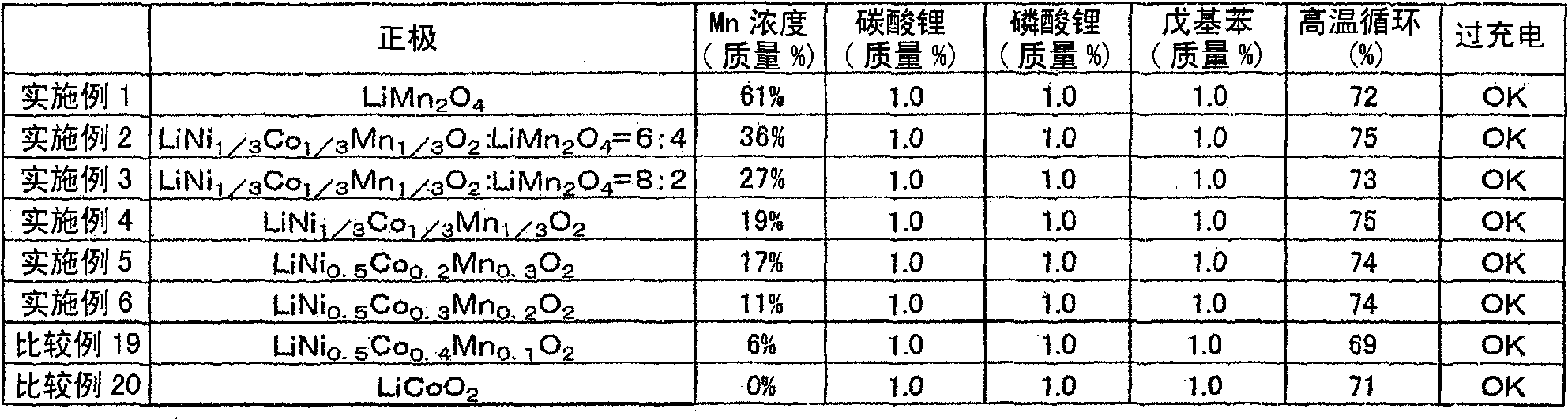

Embodiment 9 and 10

[0070] The battery of embodiment 9 and 10 uses LiNi identical with embodiment 3 1 / 3 co 1 / 3 mn 1 / 3 o 2 : LiMn 2 o 4 =8:2 As the positive electrode active material, the content of the positive electrode active material and lithium carbonate in the positive electrode mixture is set to the same content as in Example 3, and the content of lithium phosphate in the positive electrode mixture is set to 0.1% by mass ( Example 9) or 5.0% by mass (Example 10), and the battery of Example 3 was produced in the same manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com