Edge face structure of laminated film, method of processing edge face, liquid ejection nozzle with processed edge face, and process for producing the same

A technology of liquid discharge and laminated film, applied in rigid/semi-rigid container manufacturing, thin material handling, container manufacturing machinery, etc., can solve the problems of safety and hygiene, and sometimes contact with ink layer, etc. Achieving sufficient safety and hygiene, ensuring the effect of safety and hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

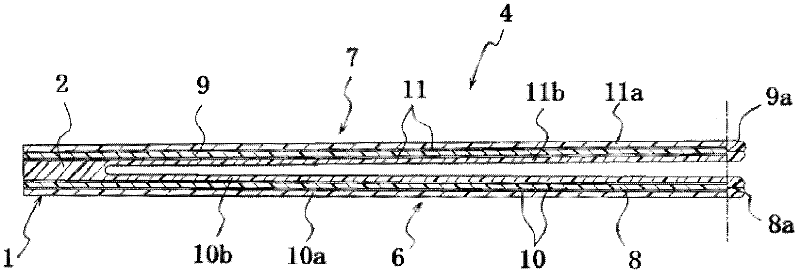

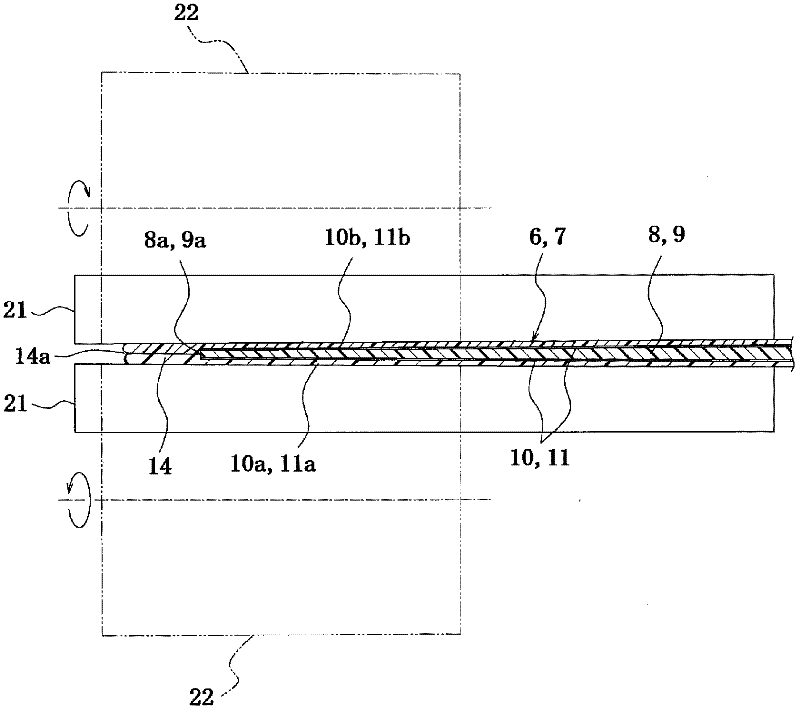

[0033] Hereinafter, embodiments of the present invention will be described by taking, as an example, a liquid discharge nozzle formed using a laminated film having a three-layer structure in which sealing layers are disposed on both sides of a base film layer.

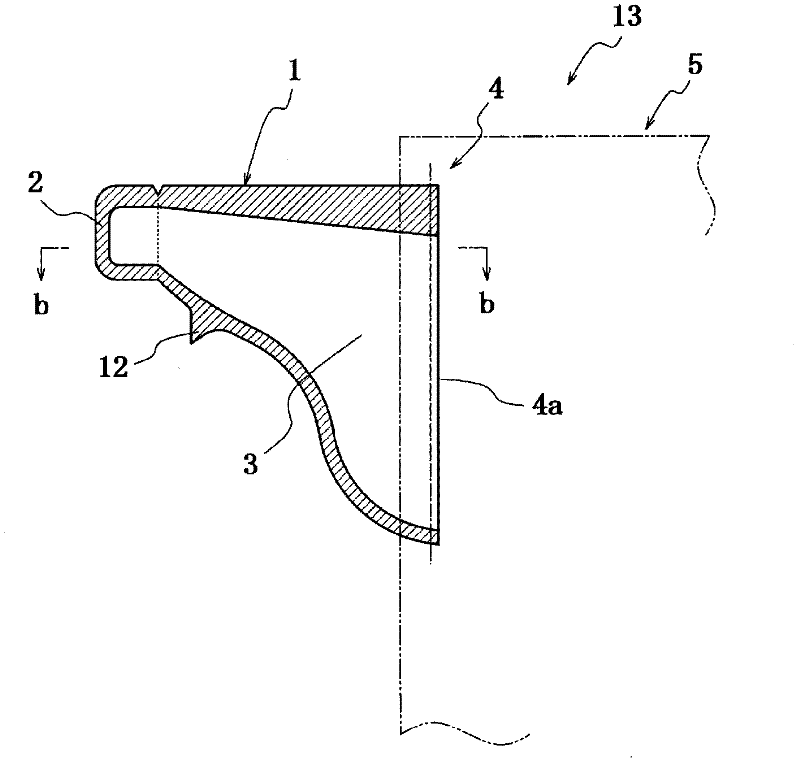

[0034] Fig. 1 is a view showing an embodiment of a liquid discharge nozzle of the present invention, and Fig. 1(b) is an enlarged cross-sectional view along line b-b of the side view of the discharge nozzle shown in Fig. 1(a).

[0035] The parts indicated by hatching in the figure indicate the welding provided on the peripheral part of the two laminated films on the front and back sides or a laminated film folded in half from the central part, except for the part that becomes the base end side of the discharge nozzle. The welded part 1 can form a discharge port at the front end of the discharge flow path 3 formed inside the welded part 1 by breaking or cutting off the welded part 2 at the front end.

[0036] A part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com