Cavity filter and communication equipment

A cavity filter and communication equipment technology, applied in the field of communication, can solve problems such as difficult clearance between circuit boards and conductors in connectors, excessive distance between screws, deformation of circuit boards, etc., to improve connection reliability and eliminate relative position errors , the effect of good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

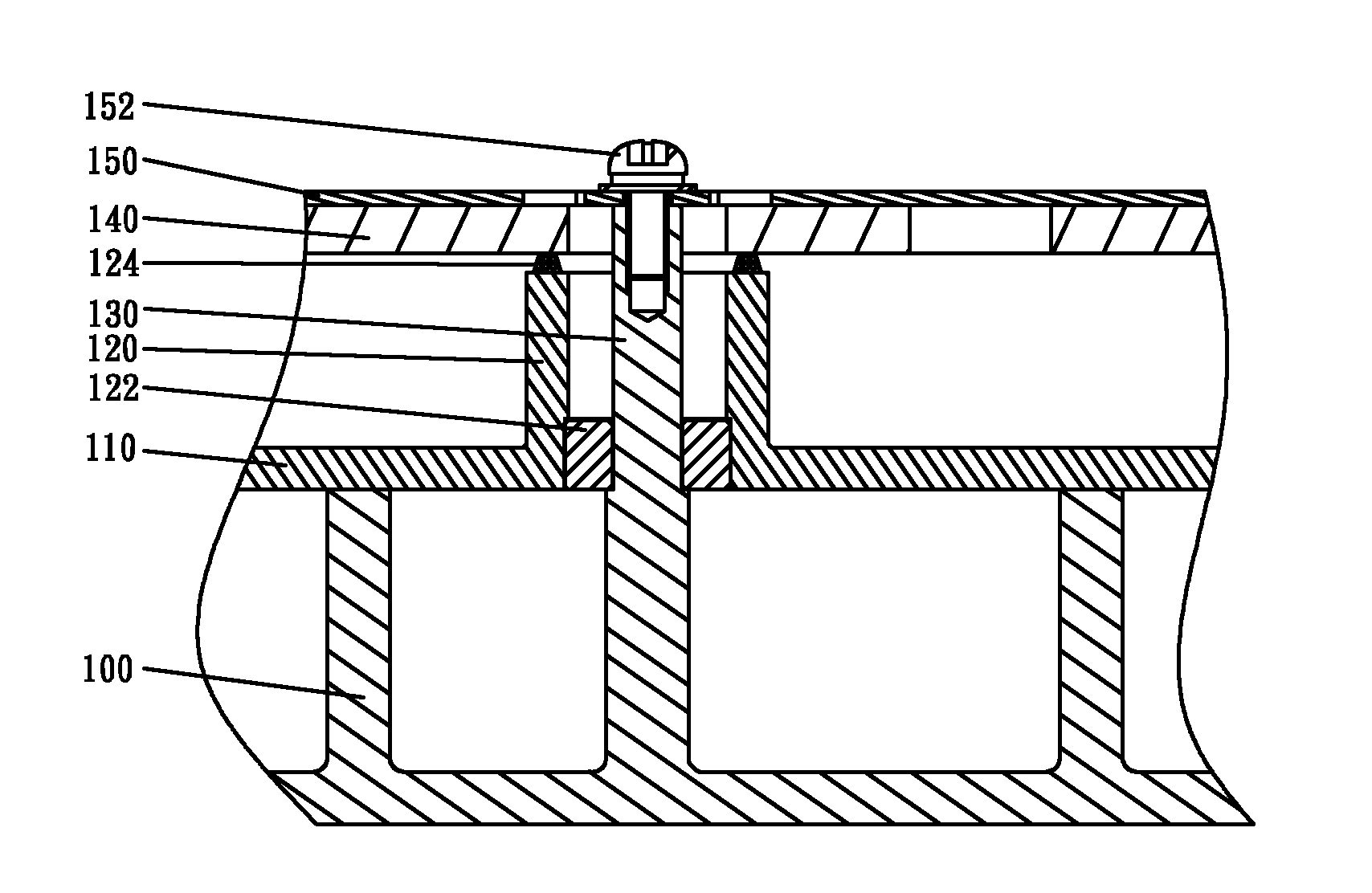

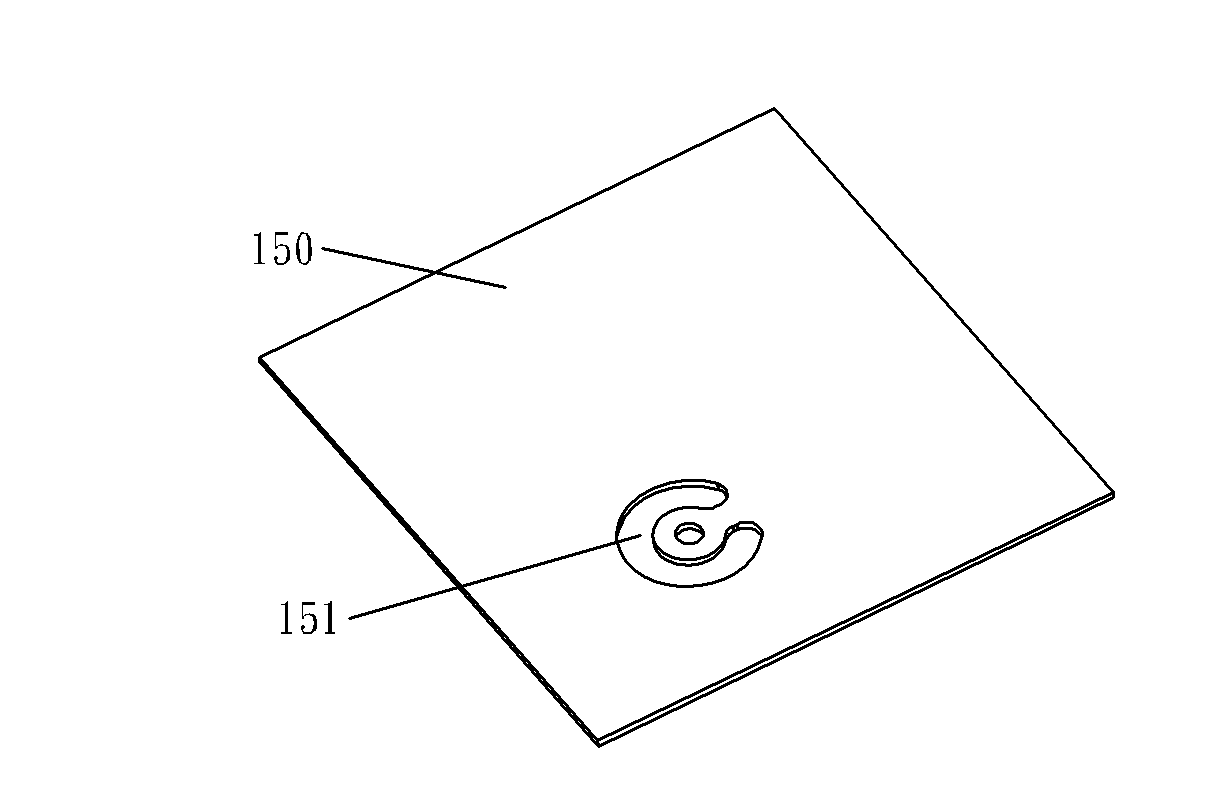

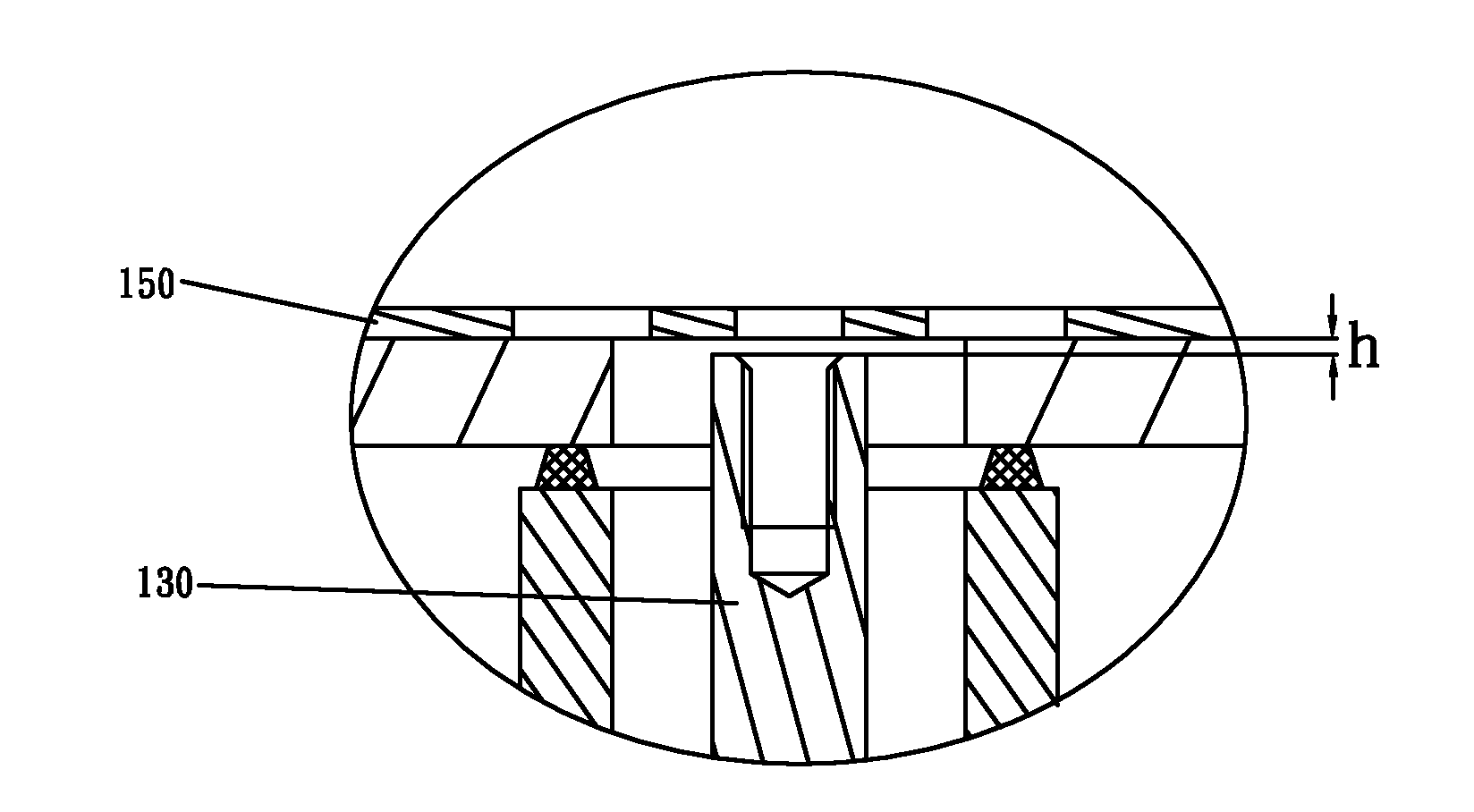

[0034] A cavity filter, the assembly structure of the inner conductor 230 of the connector and the outer circuit board 250 is shown in 2a.

[0035] See Figure 2a , the inner conductor 230 of the connector is in good contact with the circuit board 250 through the conductive elastic member 260 .

[0036]In this embodiment, the conductive elastic member 260 is in the shape of a strip. The first end 262 of the conductive elastic member 260 is connected to the resonator or cavity (not shown) of the cavity filter, and the second end of the conductive elastic member 260 264 is connected to the bottom 234 of the inner conductor 230 of the connector. Wherein, the top 232 of the inner conductor 230 of the connector is provided with a screw hole (not marked), and the circuit board 250 is provided with a matching through hole (not marked), and the inner conductor 230 of the connector passes through the screw 252 of the circuit board 250 and the circuit board 250 connected.

[0037] It...

Embodiment 2

[0044] A cavity filter, the assembly structure of the connector inner conductor 330 and the external circuit board 350 is as follows Figure 3a shown. See Figure 3a , the inner conductor 330 of the connector is in good contact with the circuit board 350 through the elastic portion 360 .

[0045] In this embodiment, the elastic part is a U-shaped elastic part 360, a screw hole (not marked) is provided on the first side wall 362 of the U-shaped elastic part 360, and a matching through hole (not marked) is provided on the circuit board 350 ), the first side wall 362 of the U-shaped elastic member 360 is connected to the signal transmission point of the circuit board 350 through the screw 352 . The second side wall 364 of the U-shaped elastic member 360 is connected to the top 332 of the inner conductor 330 of the connector.

[0046] In the embodiment of the present invention, the second side wall 364 of the U-shaped elastic member 360 and the top 332 of the inner conductor 33...

Embodiment 3

[0053] A cavity filter, the inner conductor of the connector is in good contact with the outer circuit board through a cup-shaped elastic member.

[0054] The bottom of the cup-shaped elastic part is connected with the top of the conductor in the connector through screws, the end of the cup-shaped elastic part is connected with the signal transmission point of the circuit board, the end of the cup-shaped elastic part is flexible, and The circuit board is resilient to good contact. In a preferred embodiment, the part of the circuit board in contact with the end of the cup-shaped elastic member is metallized to ensure good signal transmission, and the inner conductor of the connector is held by the elastic action of the end of the cup-shaped elastic member. Good contact between the inner conductor and the circuit board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com