LVDS (Low Voltage Differential Signaling) driver

A driver and input buffer technology, applied in the field of electronics, can solve the problems of output change, impossible instantaneous conversion and timely response, etc., to reduce the gate voltage deviation and achieve the effect of dynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

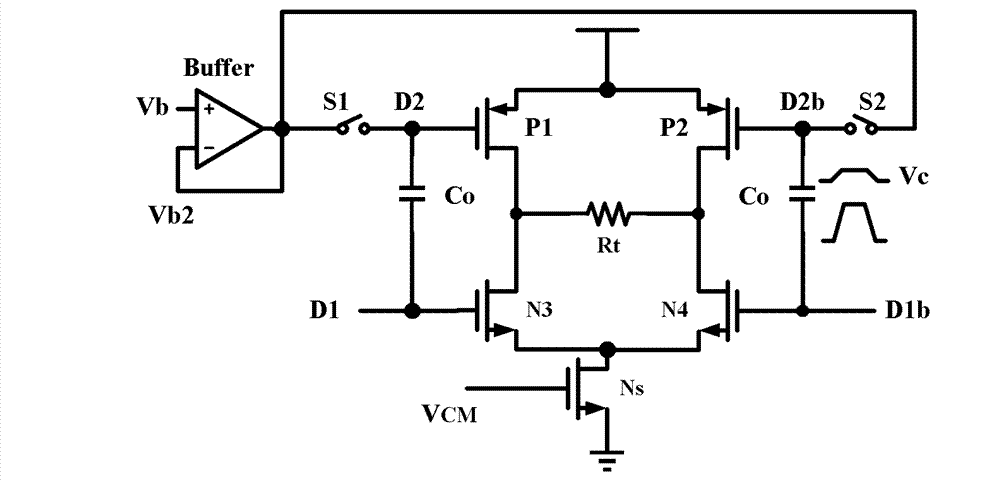

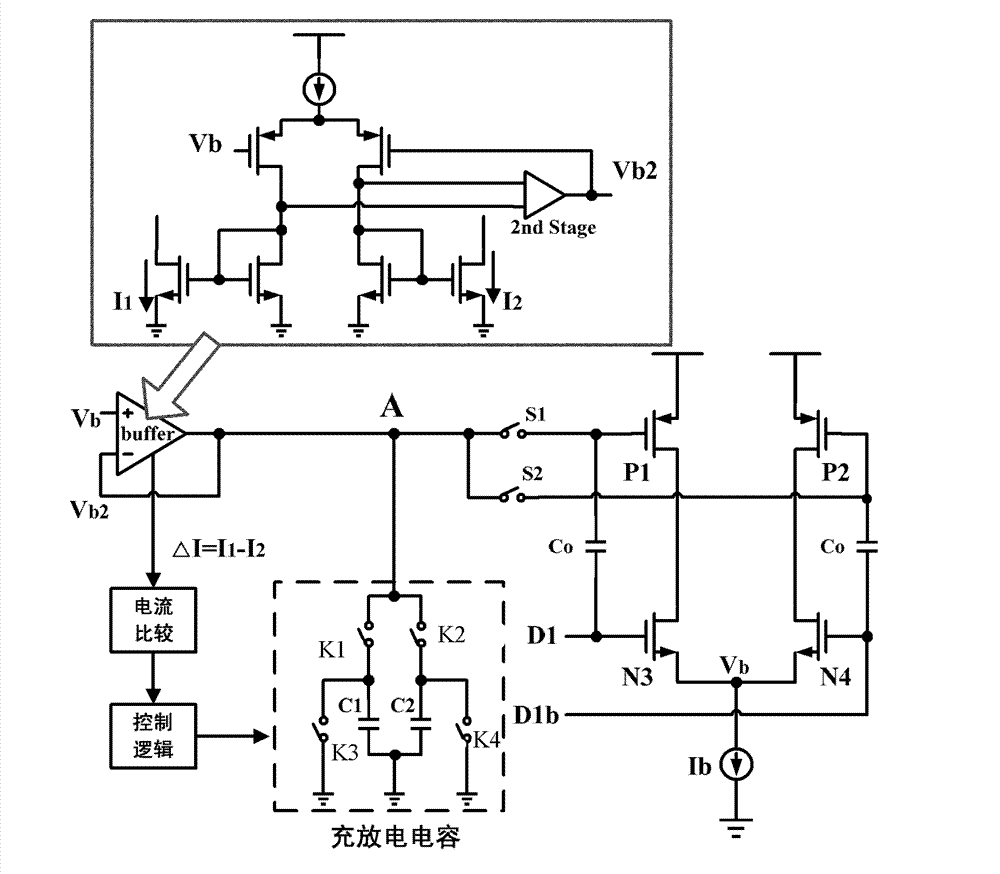

[0014] see figure 2 .

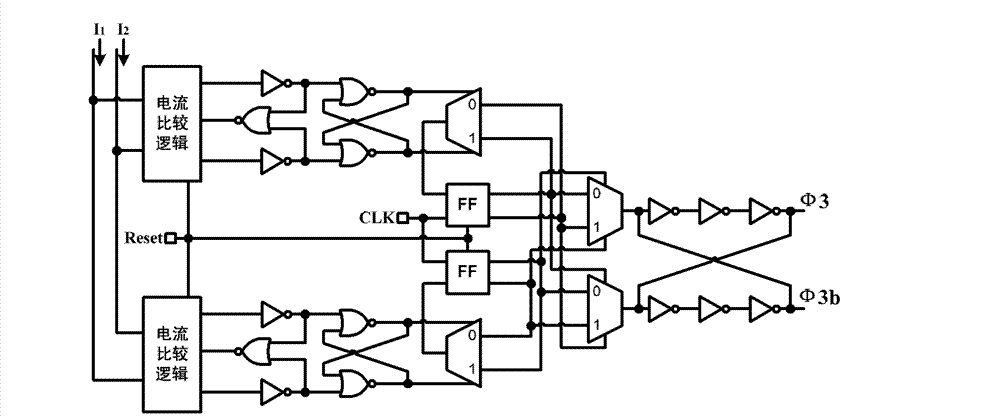

[0015] The LVDS driver of the present invention includes an input buffer unit and a drive unit, and also includes a charge and discharge control unit, and the charge and discharge control unit includes a voltage difference / current difference conversion unit, a current comparison unit, a control logic unit, and a charge and discharge unit; a current comparison unit The voltage difference / current difference conversion unit is connected to the input buffer unit; the control logic unit is connected to the current comparison unit, and is connected to the control terminal of the charging and discharging unit; the output terminal of the charging and discharging unit is connected to the output terminal of the input buffering unit. The charging and discharging unit includes a first capacitor branch and a second capacitor branch connected in parallel between the output terminal of the charging and discharging unit and the ground level, and the first capacitor br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com