Device and method for the degassing of dusts

A gas device and dust technology, applied in chemical instruments and methods, separation methods, gasification processes, etc., can solve problems such as increasing time and agglomeration of loose materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

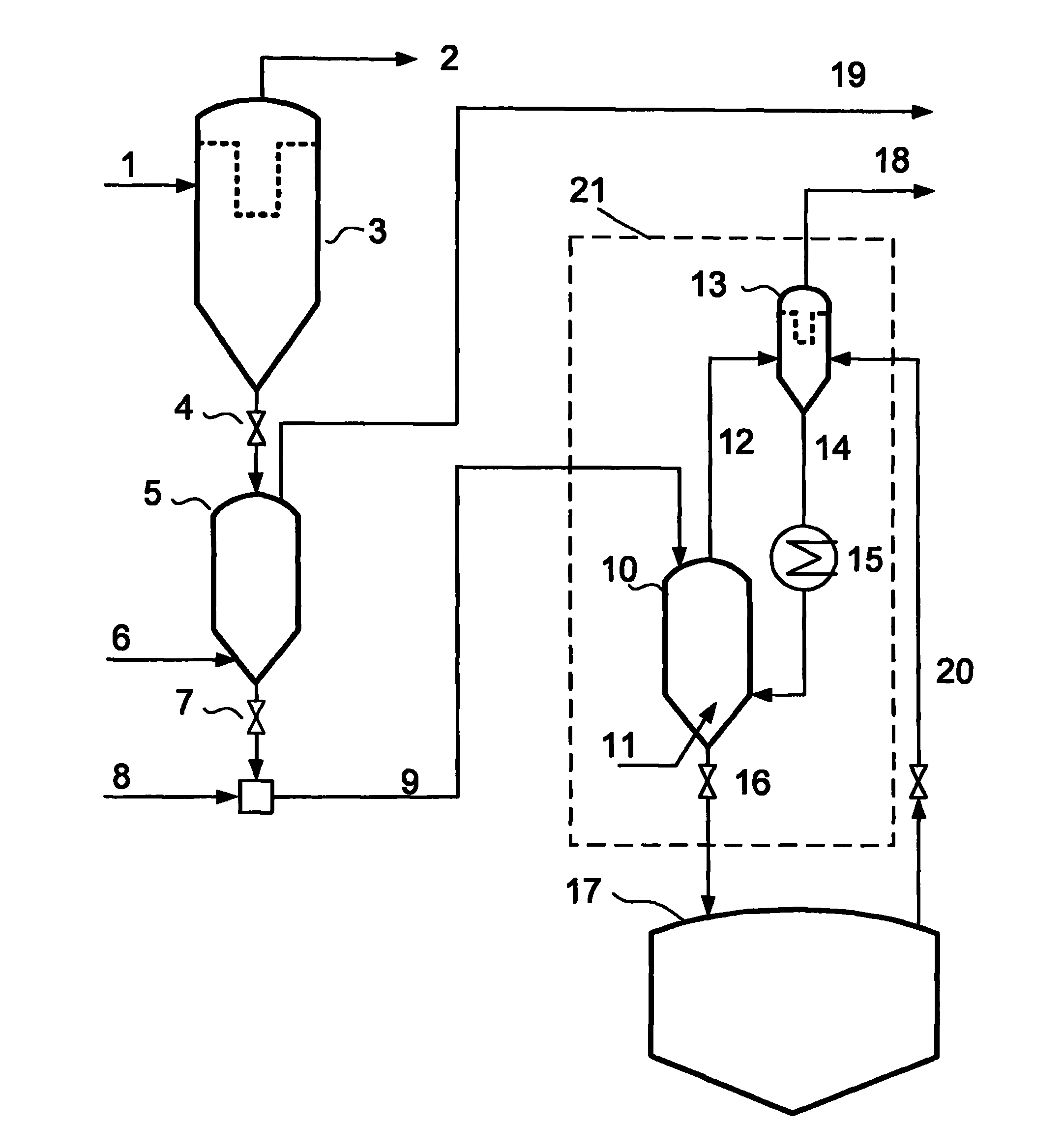

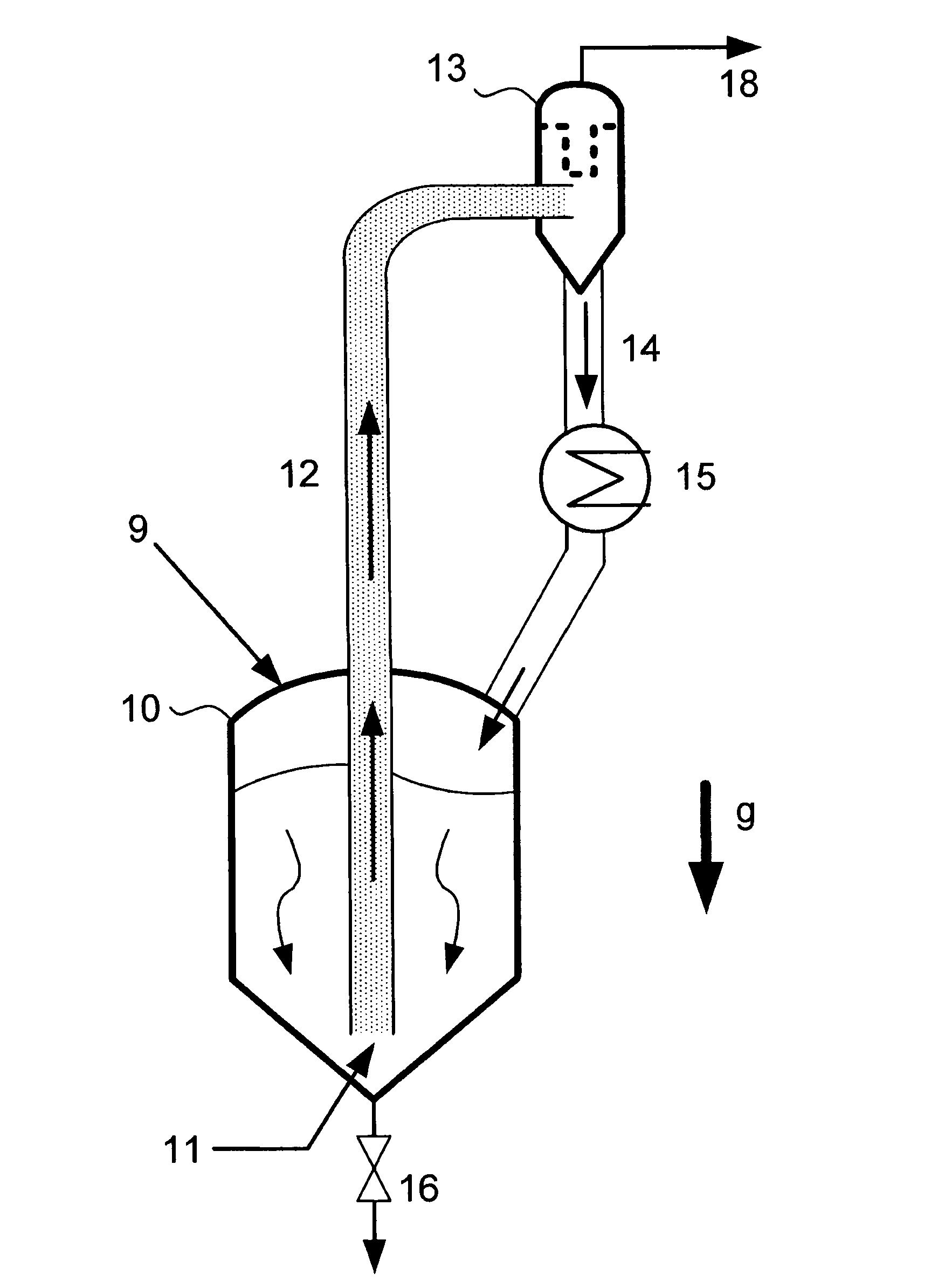

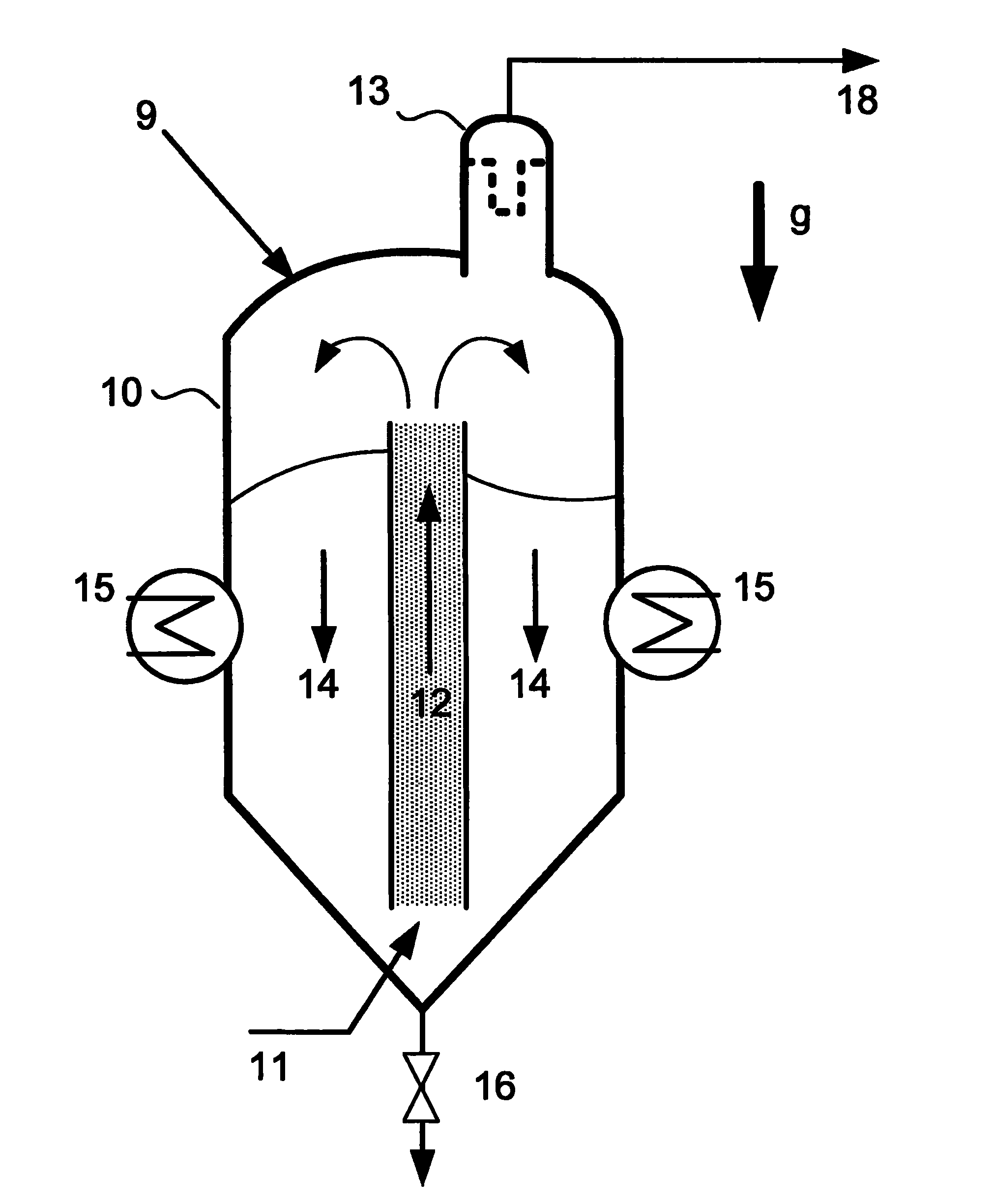

[0034] The pressurized synthesis gas 1 containing fly ash is introduced into a fly ash separator 3 which can be designed as a filter or a cyclone. Here, dedusted synthesis gas 2 and fly ash 4 are obtained, the latter being introduced into a combination container 5 . It is unavoidable here that a small amount of synthesis gas enters the combination container 5 together in the interstitial volume of the granular bulk material. In the combination container 5, the fly ash, which is still under pressure, is decompressed to a lower pressure level. A batch of solids 7 is then conveyed via a pneumatic conveying line 9 into the gas exchange vessel 10 of the gas exchange device 21 by adding conveying gas 8 . In order to compensate for the volume of the solids conveyed out of the combination container 5 and to maintain the pressure in the combination container 5 used as a delivery container during the discharge of the fly ash, an exchange gas 6 is added to the combination container 5 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap