Electro-Fenton reaction waste water treatment equipment

A technology for wastewater treatment and equipment, applied in electrochemical water/sewage treatment, water/sewage treatment, oxidized water/sewage treatment, etc., to achieve the effects of reducing treatment costs, no secondary pollution, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

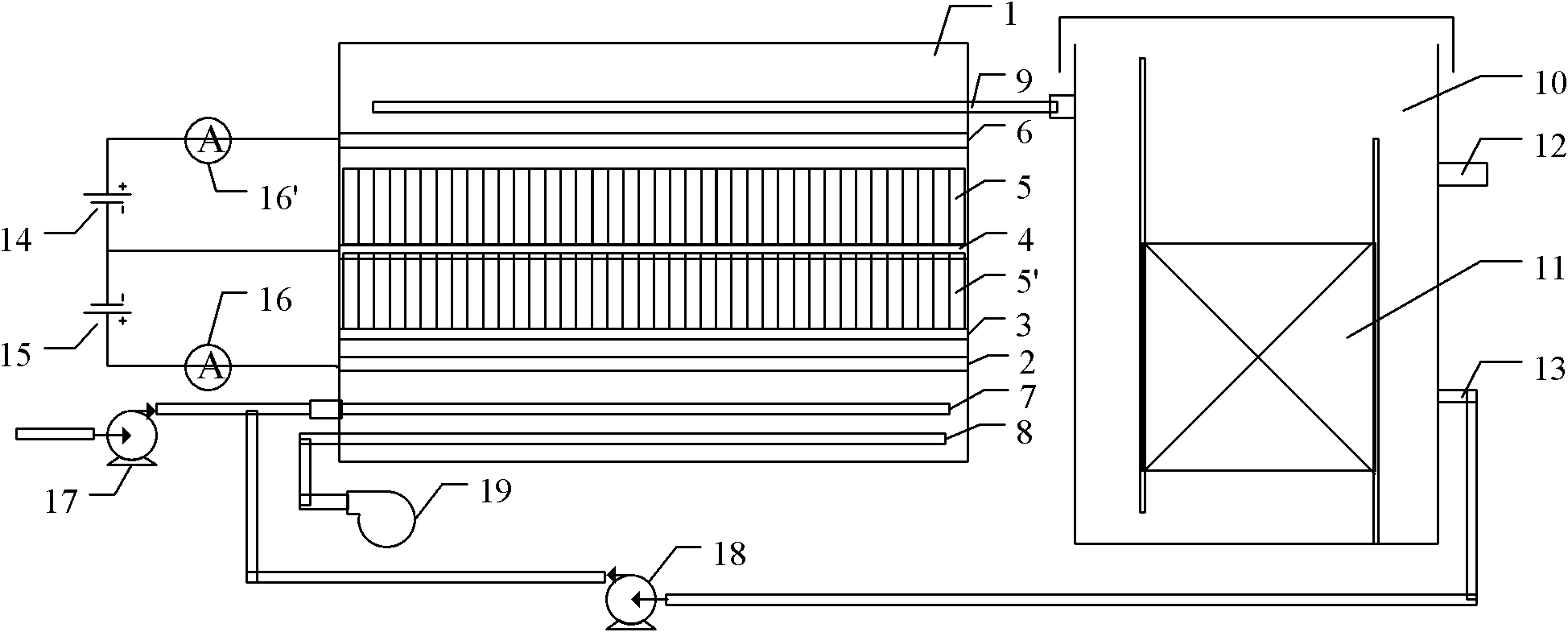

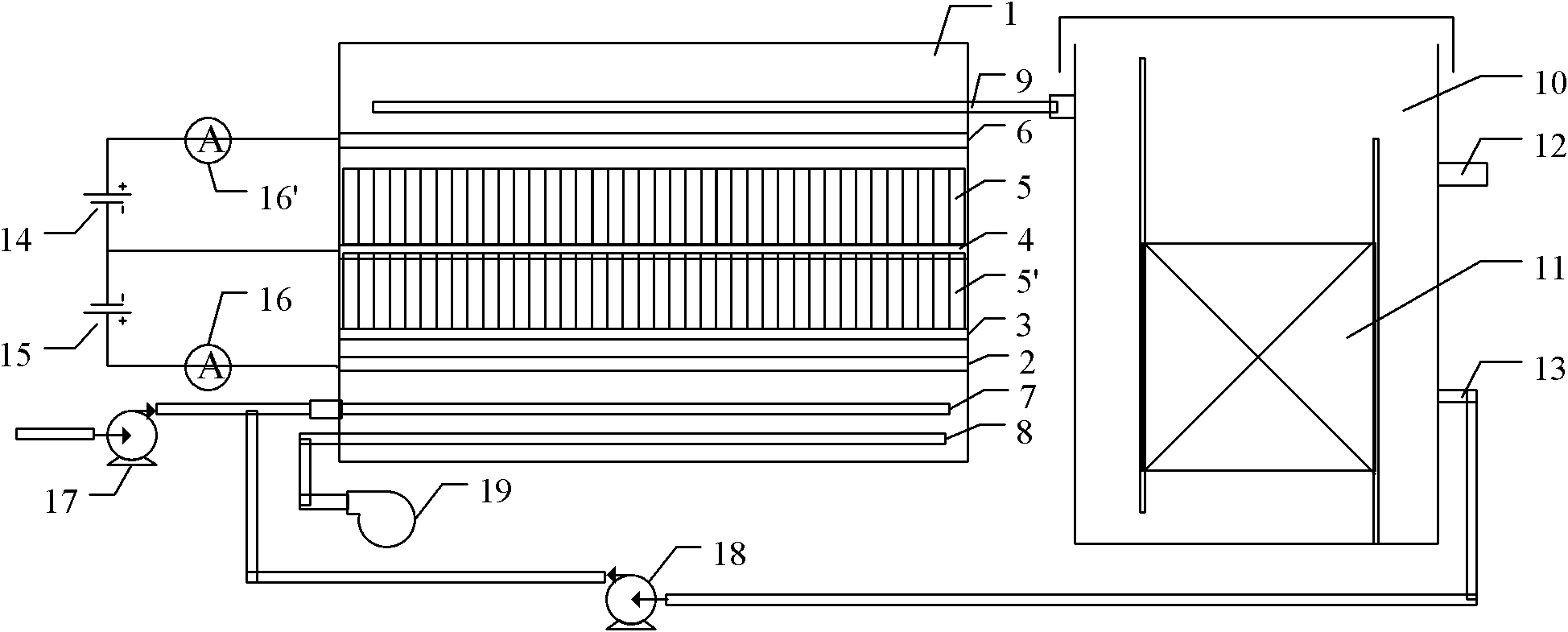

[0029] like figure 1 As shown, it is an electro-Fenton reaction wastewater treatment equipment according to an embodiment of the present invention, which includes an electro-Fenton main body device 1 and a deep reactor 10. The electro-Fenton main body device 1 is sequentially provided with horizontally parallel opposite first from bottom to top. Anode plate 2, cathode plate 4, second anode plate 6, the upper and lower sides of the cathode plate 4 are provided with extended cathodes 5, 5' in close contact with them, and the cathode plate 4 and the extended cathodes 5, 5' form an extension The expanded integral cathode is fixed inside the electro-Fenton main device 1 through the cathode support plate 3 located above the first anode plate 2. The bottom of the electro-Fenton main device 1 is provided with a water inlet and water distribution pipe 7, an air inlet and a ventilator. The gas pipe 8 has a water outlet pipe 9 connected to the deep reactor 10 on the upper part, and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com