Three-phase separator of efficient anaerobic bioreactor

A three-phase separator and anaerobic biological technology, applied in the field of wastewater treatment, can solve the problems such as the inability to effectively separate small granular sludge and flocculent sludge, affecting the effluent quality and subsequent treatment process, and reducing the treatment efficiency of the reactor. , to achieve the effect of avoiding sludge loss, simple structure, and enhanced resistance to load impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

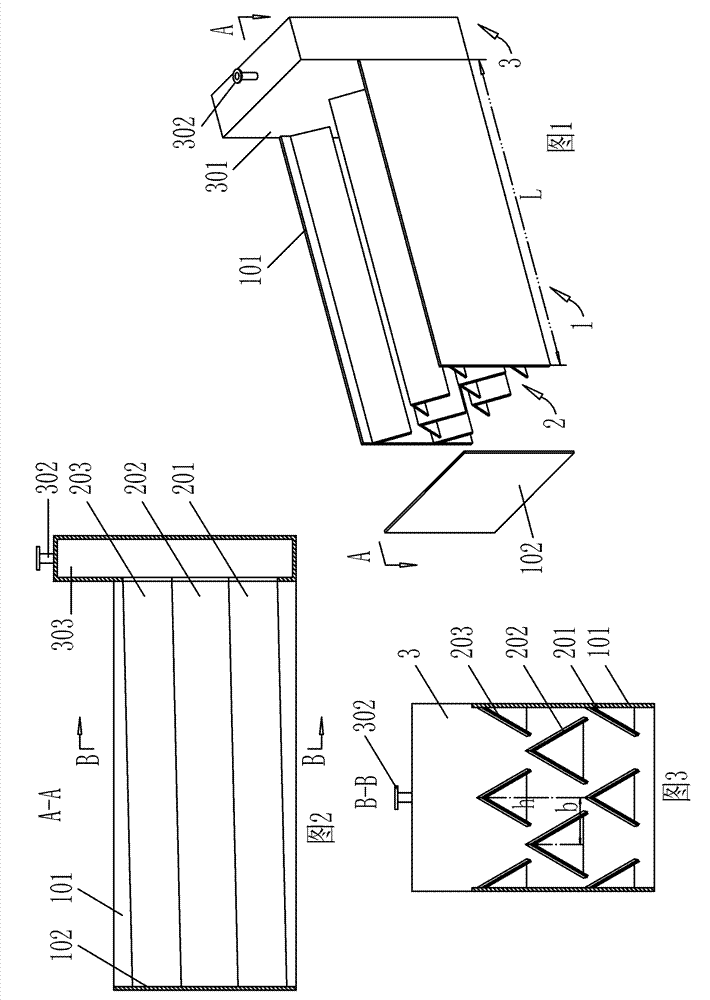

[0023] refer to figure 1 , figure 2 As shown, a three-phase separator for an efficient anaerobic bioreactor mainly includes components such as a three-phase separator box 1, a gas collection hood 2, and a biogas storage chamber 3; the three-phase separator box 1 is up and down An open rectangular structure with a length of 4900mm, a width of 1900mm, and a height of 1800mm. The material is made of polyester fiberglass. One end of the side plates 101 of the box body 1 is fixedly connected with the outer shell 301 of the rectangular biogas storage room 3, and the other end is connected with the box The body sealing plate 102 is fixedly connected, and the top of the biogas storage chamber 3 is provided with an air outlet 302; the gas collecting hood 2 is integrally formed by a mold at one time, and there is no air leakage.

[0024] Also refer to image 3 As shown, the described three-phase separator box 1 is equipped with multi-layer angle steel 103, and multi-layer angle steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com