Multi-layer inner flame combustor and gas cooker with same

A burner and inner cavity technology, applied in the field of gas stoves, can solve the problems of difficulty in further optimizing the size of the main body of the fire distributor, limitations in the promotion and application of multi-layer inner flame burners, unfavorable burner structure size, etc., to increase heat exchange The area and heat exchange time are conducive to popularization and application, and the effect of energy saving is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

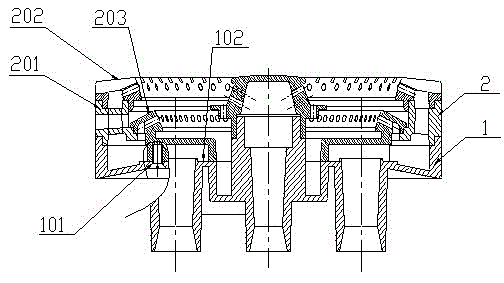

[0040] Such as figure 1 As shown, the present embodiment is an upper-intake multi-layer internal flame burner, which includes a burner body 1 and a fire distributor device 2, and the burner body and the fire distributor device are combined together by a cylindrical surface and a plane; the burner body is The upper air inlet structure; the fire distributor device is composed of the fire distributor main body 201, the upper fire cover 202, and the lower fire cover 203. The inner cavity of the fire distributor main body is connected with the inner cavity of the burner main body; The main body has several screw holes 101 at the position corresponding to the lower fire cover, and is provided with a mounting plane 102 corresponding to the lower fire cover; through screws, the lower fire cover is connected with the fire distributor main body and the burner main body.

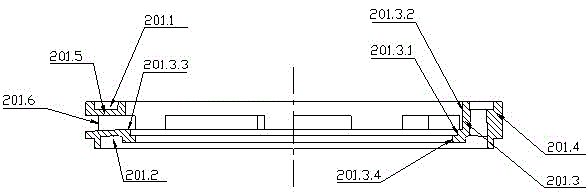

[0041] Such as figure 2 As shown, the main body 201 of the fire distributor is provided with a separation layer 201...

Embodiment 2

[0045] This embodiment is except following feature, and other is all identical with embodiment 1:

[0046] Such as Figure 7 As shown, this embodiment is a multi-layer internal flame burner with downward air intake, which includes a burner body 1 and a flame distributor device 2, and the burner body 1 and the flame distributor device 2 are combined together by a cylindrical surface; the burner body It is a lower air intake structure, and there is no screw hole 101 on the burner body; the inner wall section of the lower fire cover 203 ( Figure 8 In 203.8) there is no inwardly protruding arc section 203.3, and there is no inner cavity 203.6 formed by the arc section; the lower fire cover passes through the inner wall section 203.8, the outer cylindrical section 203.9 and the main body of the fire distributor and the burner. The main body snaps together.

Embodiment 3

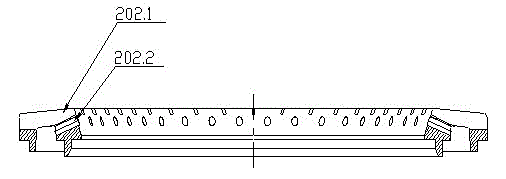

[0048] There is no figure in this embodiment, refer to the related figure of embodiment 1. Except that the setting of the fire hole of the upper fire cover is different from that of Example 1, all the others are the same as that of Example 1. The difference is that there are dozens of strip-shaped fire holes 202.1 on the top of the upper fire cover (the number of fire holes can be determined according to actual needs); there are two circles of circular fire holes on the inner conical surface of the upper fire cover (according to actual needs). Determine the number of fire holes), and two circles of circular fire holes are evenly distributed along the circumference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com