Method for cultivating Hemifusus tuba with net cage in hanging way

A breeding method and technology of snails, which are applied in the field of hanging and raising snails in cages, can solve problems such as cannibalism, and achieve the effects of improving the living environment, increasing the survival rate and growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

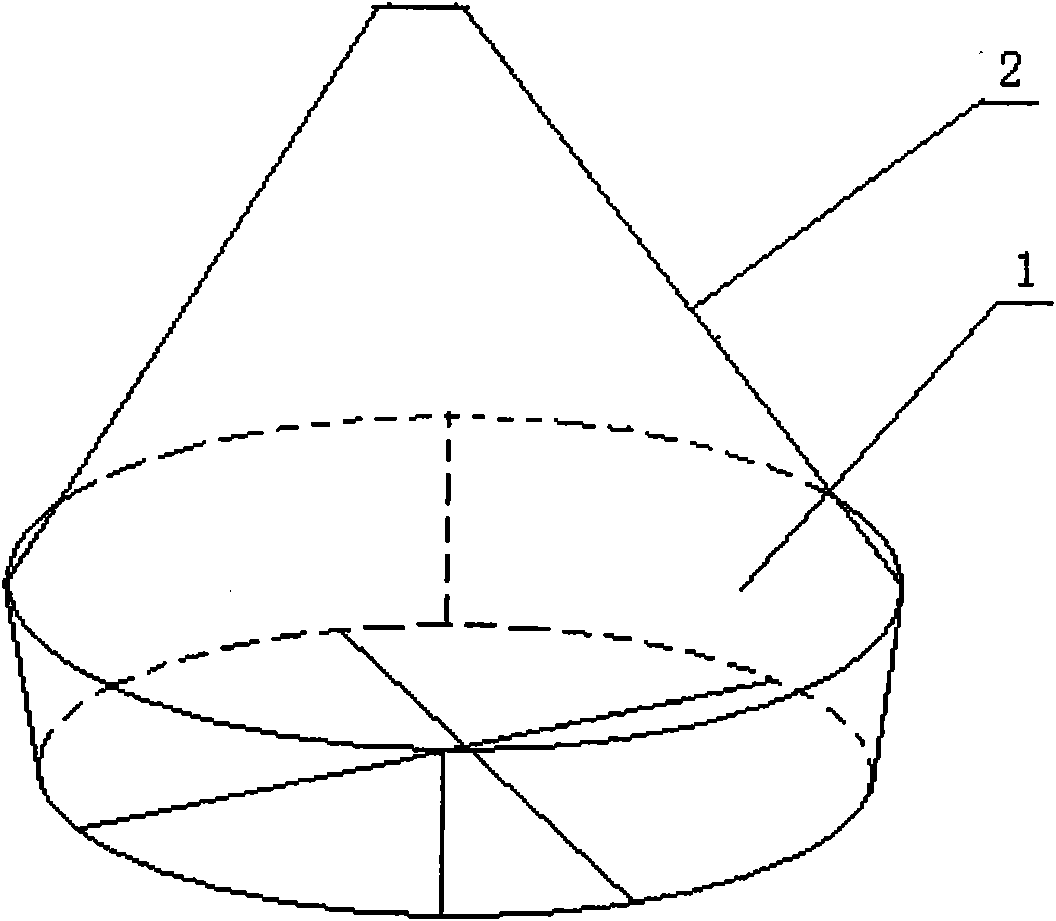

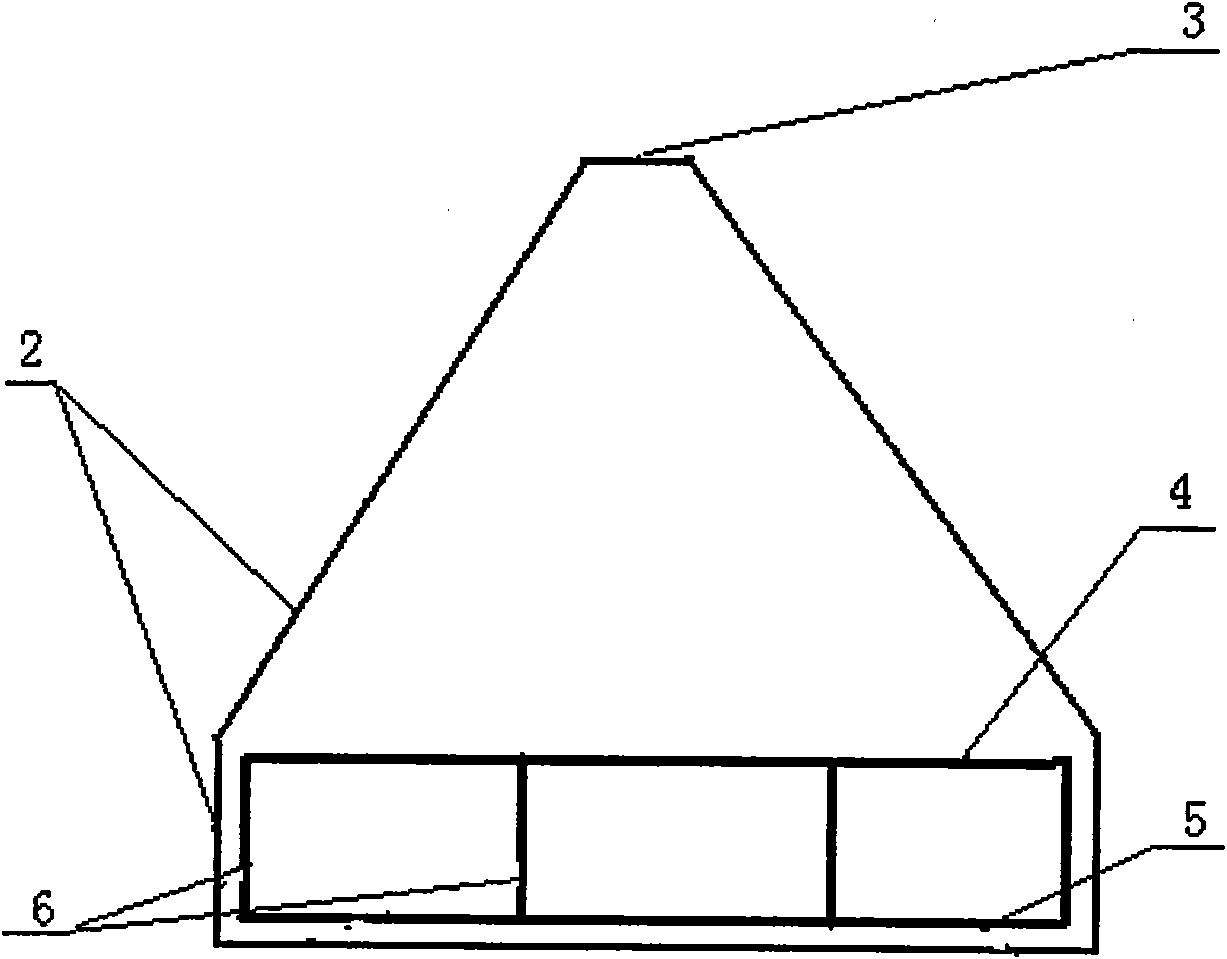

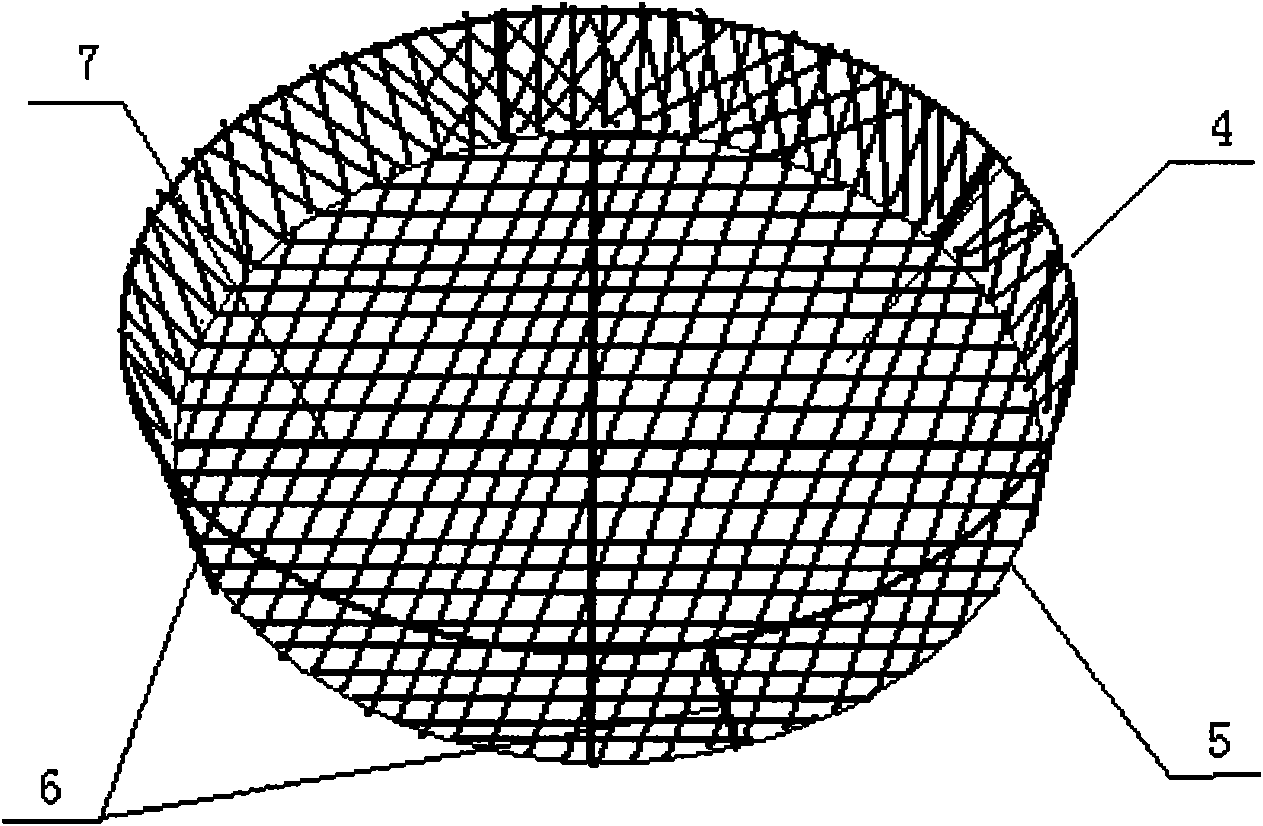

[0027] Embodiment 1: Utilize diameter specification to be 45cm, single-layer cage type, the culture cage of cage mesh size 0.5cm carries out tube angle snail suspension culture. The culture cage is fixedly tied on the floating rope of the cultured shrimp pond, the floating rope is 60m long from east to west, and the water depth of the pond is 1.5m. Breeding cages were placed in a water layer at a depth of 0.7m, and the distance between cages was 0.2m. Ten snail seedlings with an average shell height of 30 mm and an average body weight of 2 g were placed in each cage. During the period of hanging snails, feed fresh oysters with shells once every 10 days. Before each feeding, remove the empty oyster shells and dirt, clean up the attached organisms inside and outside the cage, and then put in a sufficient amount of fresh oysters with shells . Usually, the cages are cleaned once every time they are fed to prevent the attached algae from clogging the mesh, and the cages will not ...

Embodiment 2

[0028] Embodiment 2: Utilize diameter specification to be 48cm, single-layer cage type, the culture cage of cage size 1cm carries out tube angle snail suspension culture. The culture cage is fixedly tied on the floating rope of the cultured shrimp pond, the floating rope is 65m long from east to west, and the water depth of the pond is 1.8m. Breeding cages were placed in a water layer with a depth of 1m, and the distance between cages was 0.5m. 20 snail seedlings with an average shell height of 34 mm and an average body weight of 2.5 g were placed in each cage. During the period of hanging snails, feed fresh oysters with shells once every 10 days. Before each feeding, remove the empty oyster shells and dirt, clean up the attached organisms inside and outside the cage, and then put in a sufficient amount of fresh oysters with shells . Usually, the cages are cleaned once every time they are fed to prevent the attached algae from clogging the mesh, and the cages will not be inv...

Embodiment 3

[0029] Embodiment 3: Utilize diameter specification to be 50cm, single-layer cage type, the culture cage of cage mesh size 1.5cm carries out tube angle snail suspension culture. The breeding cage is fixedly tied on the floating rod of the cultured shrimp pond, the floating rod is 70m long from east to west, and the depth of the pond water is 2m. Breeding cages were placed in a water layer at a depth of 1.4m, and the distance between cages was 1m. 50 snail seedlings with an average shell height of 40 mm and an average body weight of 3 g were placed in each cage. During the period of hanging snails, feed fresh oysters with shells once every 10 days. Before each feeding, remove the empty oyster shells and dirt, clean up the attached organisms inside and outside the cage, and then put in a sufficient amount of fresh oysters with shells . Usually, the cages are cleaned once every time they are fed to prevent the attached algae from clogging the mesh, and the cages will not be inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com