Special anti-dazzle transfer printing film for polycarbonate and using method thereof

A polycarbonate, anti-glare technology, applied in the directions of copying/marking methods, chemical instruments and methods, printing, etc., can solve the problems of high production cost, complex production process, short supply of anti-glare polycarbonate sheets in the market, etc. The effect of low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments.

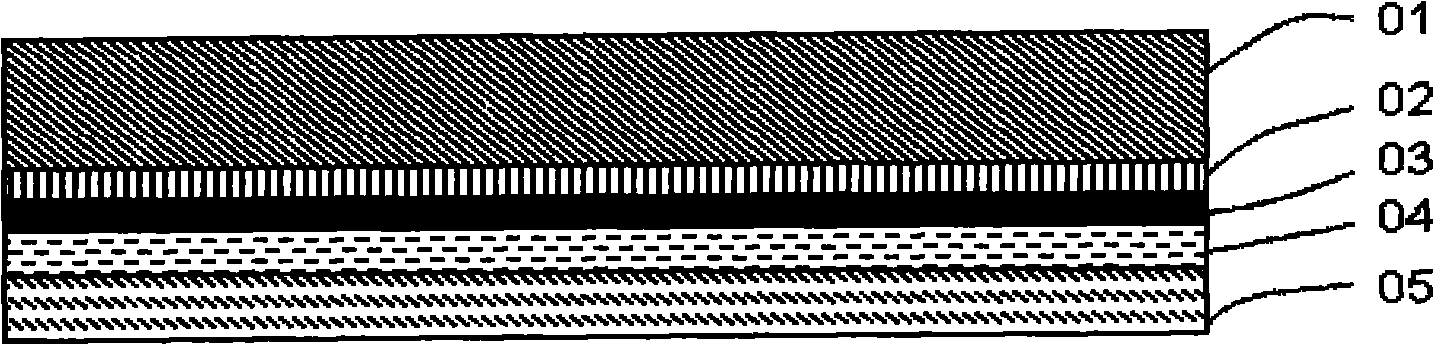

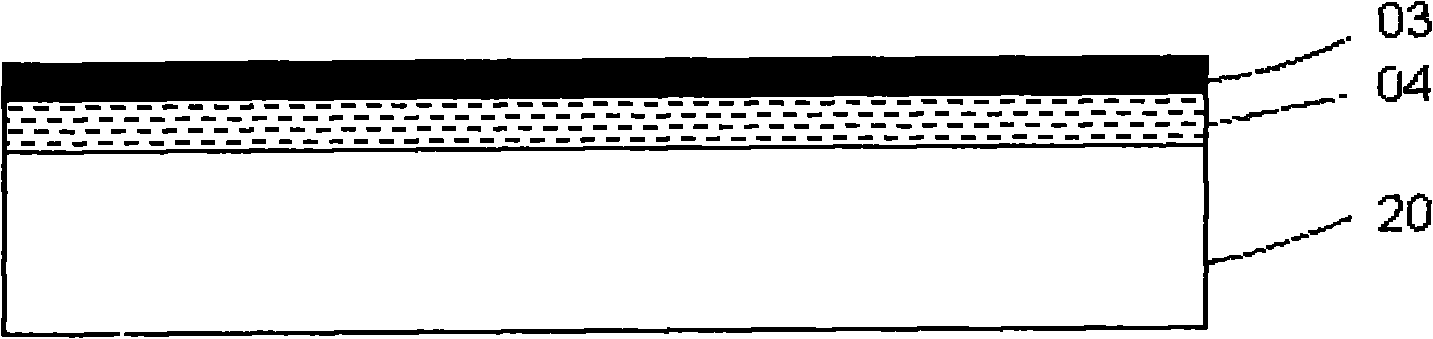

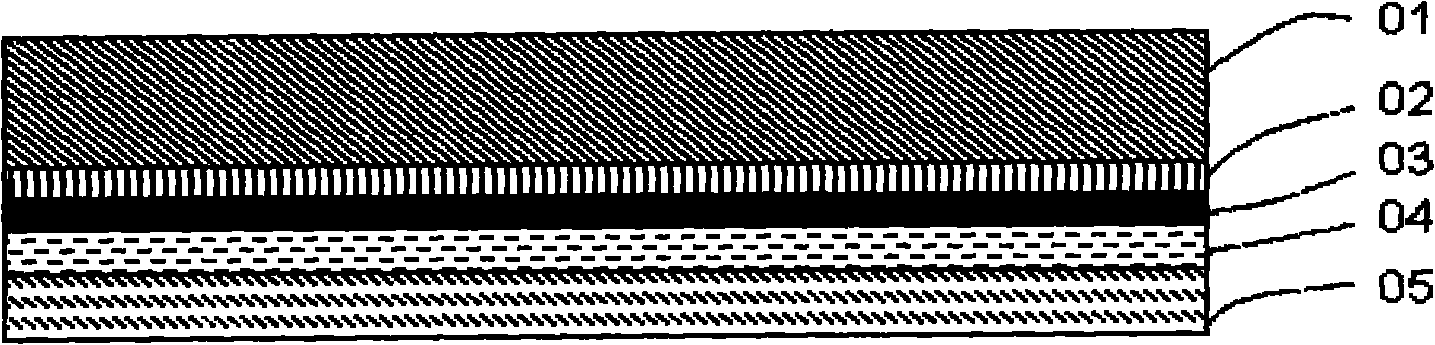

[0019] Such as figure 1 The illustrated anti-glare transfer film specifically for polycarbonate is provided with a PET layer 01, a release layer 02, an anti-glare layer 03, an adhesive layer 04 and a protective film layer 05 from top to bottom.

[0020] PET layer 01: The PET layer 01 is a biaxially stretched PET film with a thickness ranging from 50-100 μm and a width ranging from 930-1250 mm, which can be recycled;

[0021] Release layer 02: This layer is a special release coating for transfer film, which is directly coated on the PET film. It has excellent peeling performance and has no obvious effect on the anti-glare performance of the final product. The thickness is 4-6μm;

[0022] Anti-glare layer 03: This layer is coated on the release layer 02 by wet coating with a layer of anti-glare layer 03 with a thickness of 4-6μm;

[0023] Adhesive layer 04: This layer is a key ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com