Method for adjusting and controlling braking force of motor

A technology of motor braking and control methods, which is applied to electric braking systems, motors, brakes, etc., and can solve problems such as low control accuracy, difficult control of frictional braking torque, and restricted control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

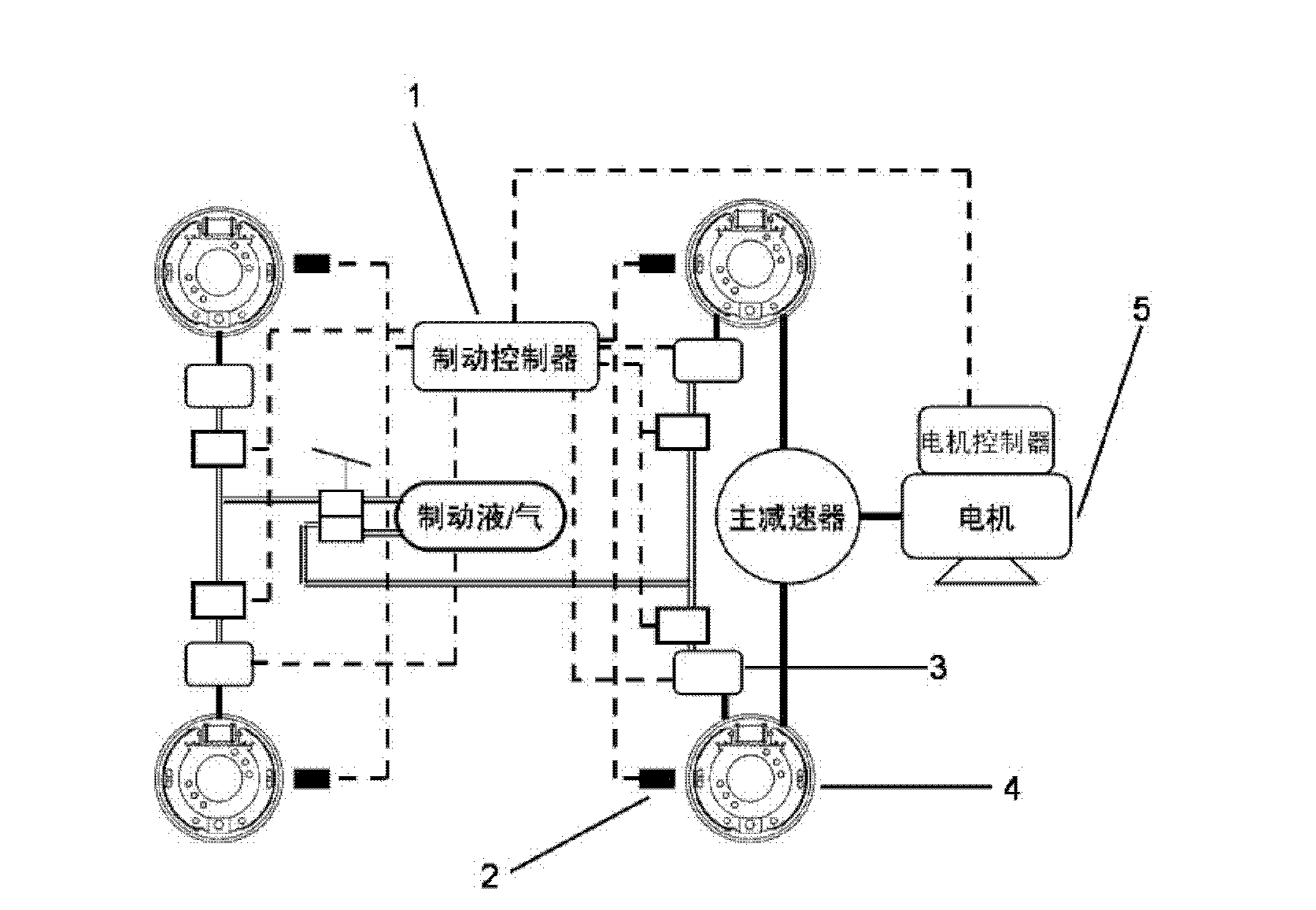

[0033] Such as figure 1 As shown, the present invention mainly includes a brake controller 1 , a wheel speed sensor 2 , a brake pressure sensor 3 , a friction brake 4 and a drive motor 5 .

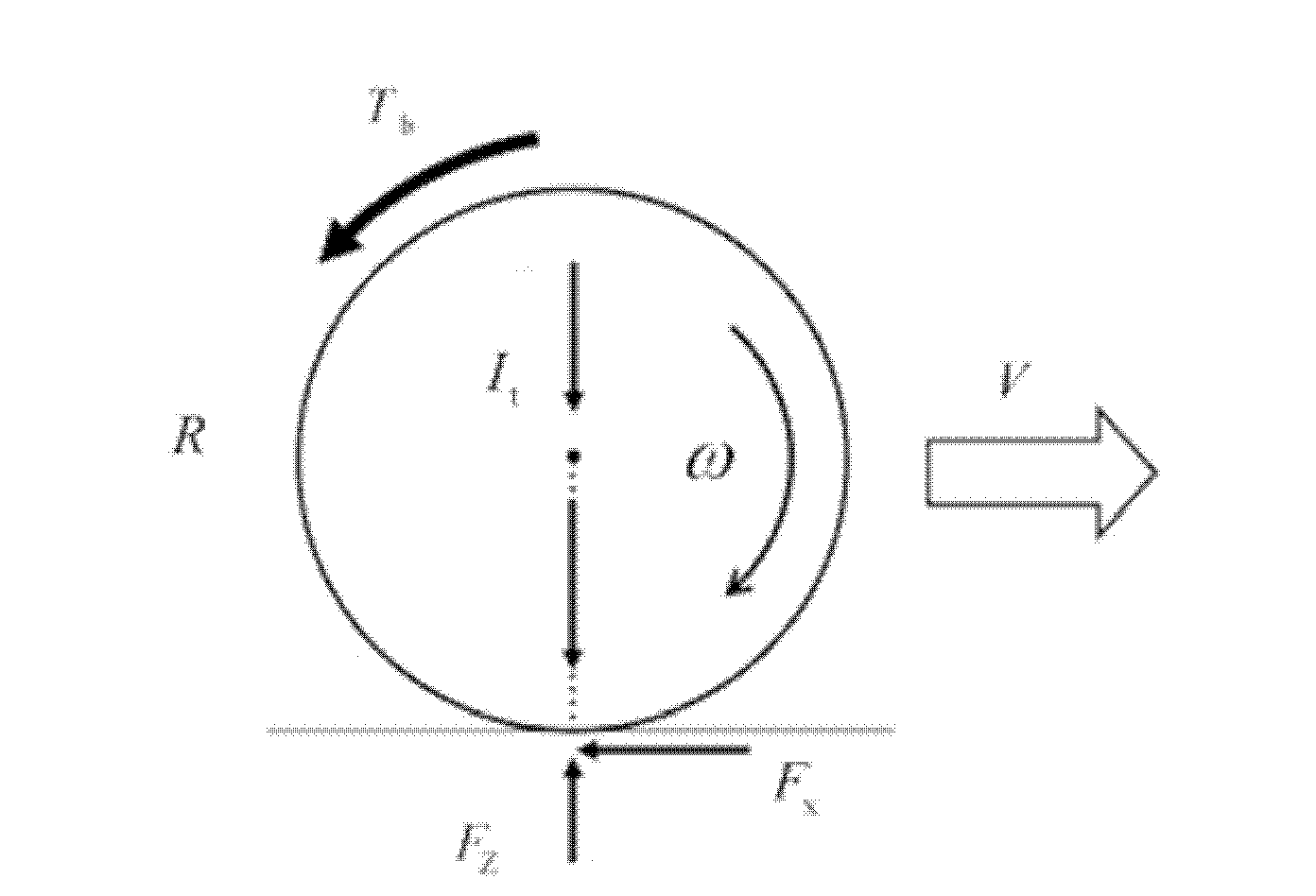

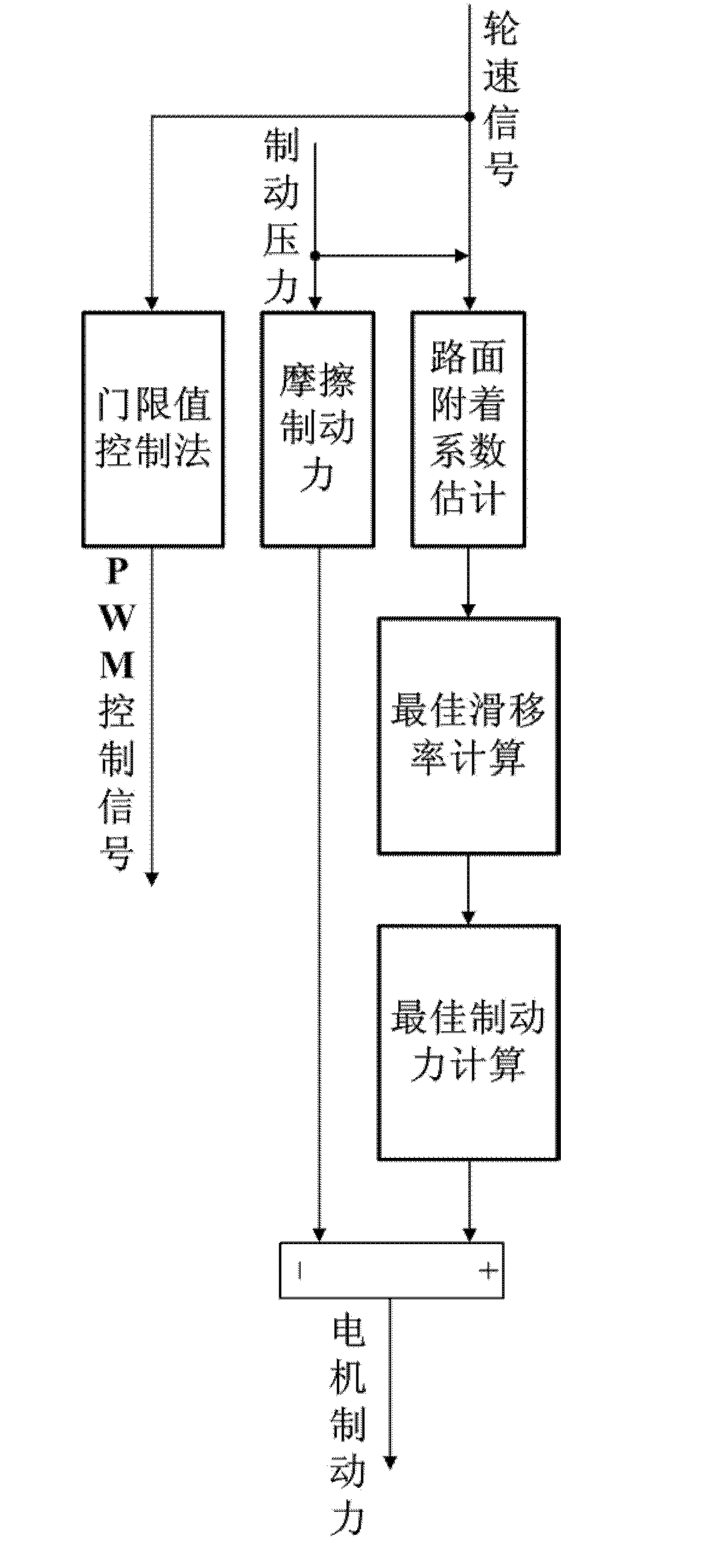

[0034] Such as figure 2 , image 3 As shown, the wheel of the car has two degrees of freedom, which are the vehicle speed V and the angular velocity ω of the wheel. f x is the longitudinal adhesion between the tire and the road surface, R is the effective rolling radius of the wheel, T b is the total braking torque, I t is the moment of inertia of the wheel. At the initial moment of each control cycle h, the motor braking force is calculated according to the data measured by the sensor in the previous cycle and the data received by CAN, and used in the next cycle. During the period h, the braking force is regarded as a certain value, and the specific calculation method is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com