Method and equipment for purifying polysilicon by utilizing shallow molten pool to carry out vacuum smelting

A vacuum smelting, polysilicon technology, applied in chemical instruments and methods, silicon compounds, sustainable manufacturing/processing, etc., can solve the problems of unfavorable solar cell popularization, slow phosphorus removal, large equipment investment, etc. The effect of good effect, high production efficiency and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for purifying polysilicon by vacuum smelting and purifying polysilicon in a shallow melting pool. Under a high vacuum condition with a vacuum degree of 0.0008 Pa, high-purity polysilicon material is first melted in a melting crucible 13 by induction heating at 1430°C to form a high-purity silicon melt 14, and Keep it liquid.

[0027] Then increase the power of the induction coil 12 to make the temperature of the silicon melt reach 1500°C, and then vertically and slowly extend the high-phosphorus and high-metal silicon rod 9 suspended above the silicon melt into the silicon melt through the suspension clamping device Among them, the front end of high-phosphorus and high-metal silicon rod 9 is continuously melted to form a shallow molten pool of high-phosphorus and high-metal, and impurity phosphorus is continuously evaporated and removed in the shallow molten pool.

[0028] Finally, after the high-phosphorus and high-metal silicon rods are completely melted into...

Embodiment 2

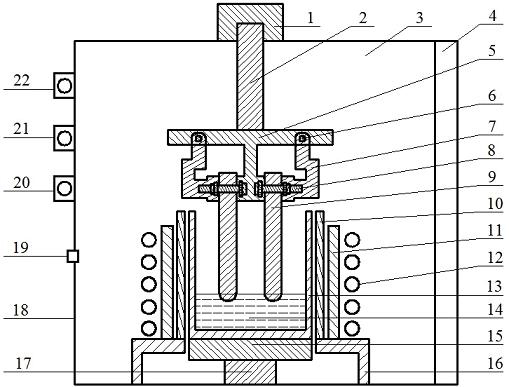

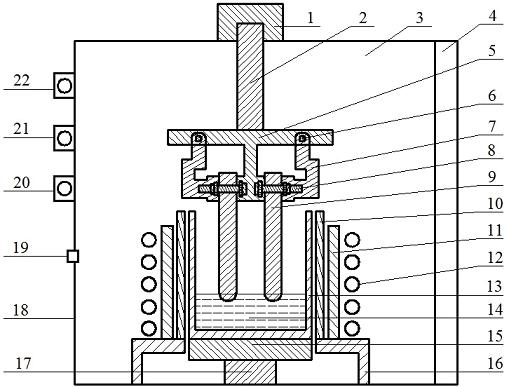

[0030] like figure 1 The equipment for purifying polysilicon by vacuum smelting and purifying polysilicon in a shallow molten pool is shown. The vacuum equipment is composed of a furnace cover 4 and a vacuum furnace wall 18 . The inner chamber of the vacuum equipment is the vacuum chamber 3 . The bottom of the vacuum chamber 3 is fixedly installed with a supporting base 16, and the supporting base 16 is equipped with an induction coil 12, a graphite sleeve 11, and a thermal insulation carbon felt 10 from the outside to the inside. The graphite sleeve 11 is used for the early stage of induction heating and the silicon material is non-conductive To heat the silicon material, the thermal insulation carbon felt 10 is used to prevent heat loss from the side wall during the directional solidification process. The bottom of the vacuum chamber in the support base 16 is equipped with a water-cooled ingot rod 17, and the graphite block 15 is installed on the water-cooled ingot rod 17. A...

Embodiment 3

[0035] Adopt the equipment described in embodiment 2 to carry out the method for purifying polysilicon by shallow melting pool vacuum smelting, its specific steps are as follows:

[0036] The first step of material preparation: lift the lifting rod 2 through the lifting electric device 1, the lifting rod 2 drives the suspension clamping device to rise to the upper limit position, add 500g of high-purity polysilicon material with a total impurity content of 0.0002% to the melting crucible 13, and then Clamp four polysilicon round rods with a mass of 1000g each, with impurity phosphorus contents of 0.0012%, 0.0015%, 0.0010%, and 0.0013%, and total metal impurity contents of 0.013%, 0.011%, 0.017%, and 0.019%, respectively. on the suspension clamp;

[0037] The second step of pretreatment: after closing the furnace cover 4, use the mechanical pump 20, the Roots pump 21 and the diffusion pump 22 to pump the vacuum to the equipment respectively, and pump the vacuum chamber 3 to a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap