DC power supply apparatus

A technology of DC power supply and rectifier circuit, which is applied to output power conversion devices, electrical components, and AC power input to DC power output, etc., and can solve the problems of high harmonic current component content, synchronous rectification, damage, etc. , to achieve the effect of reducing the high-order harmonic current, improving the power factor of the power supply, and high-order harmonic current being efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

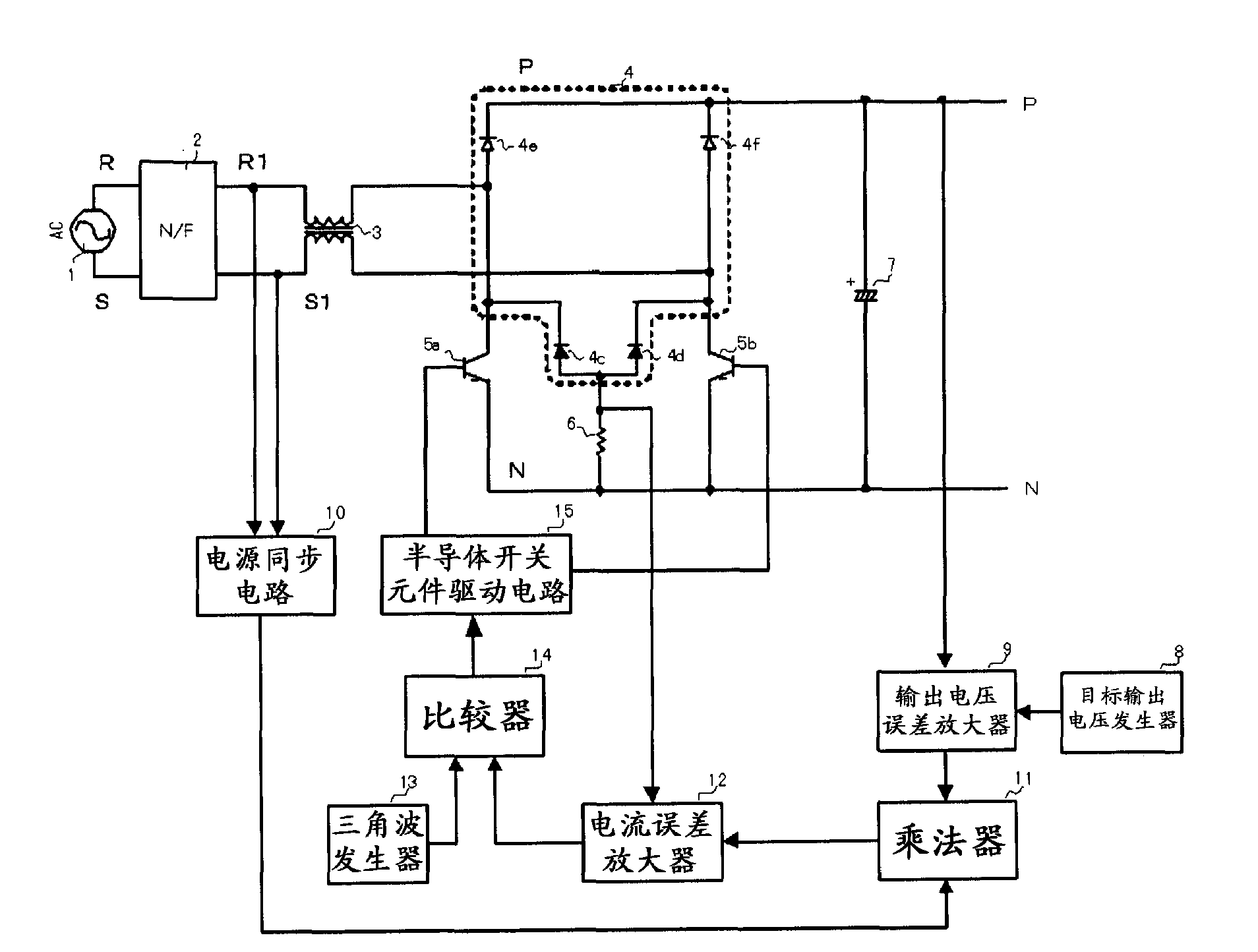

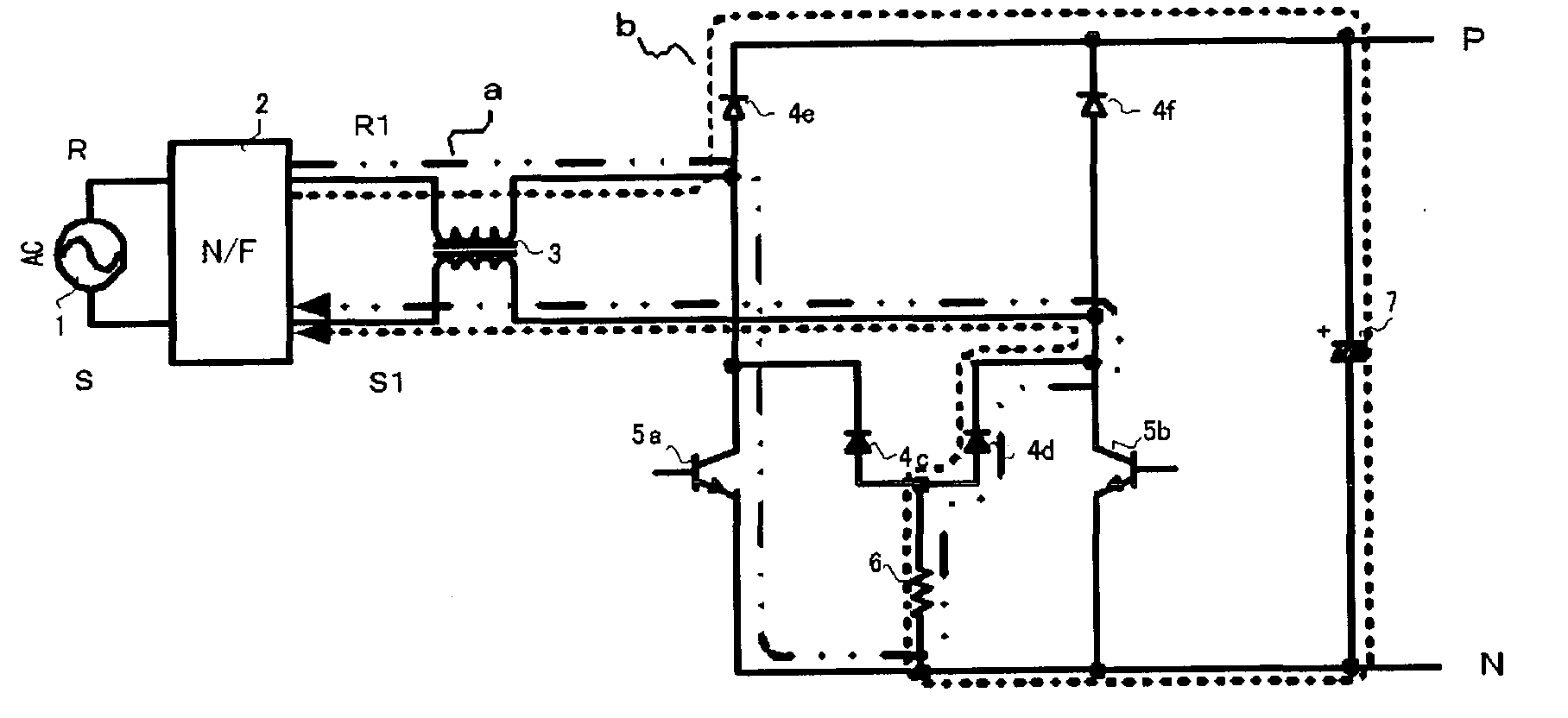

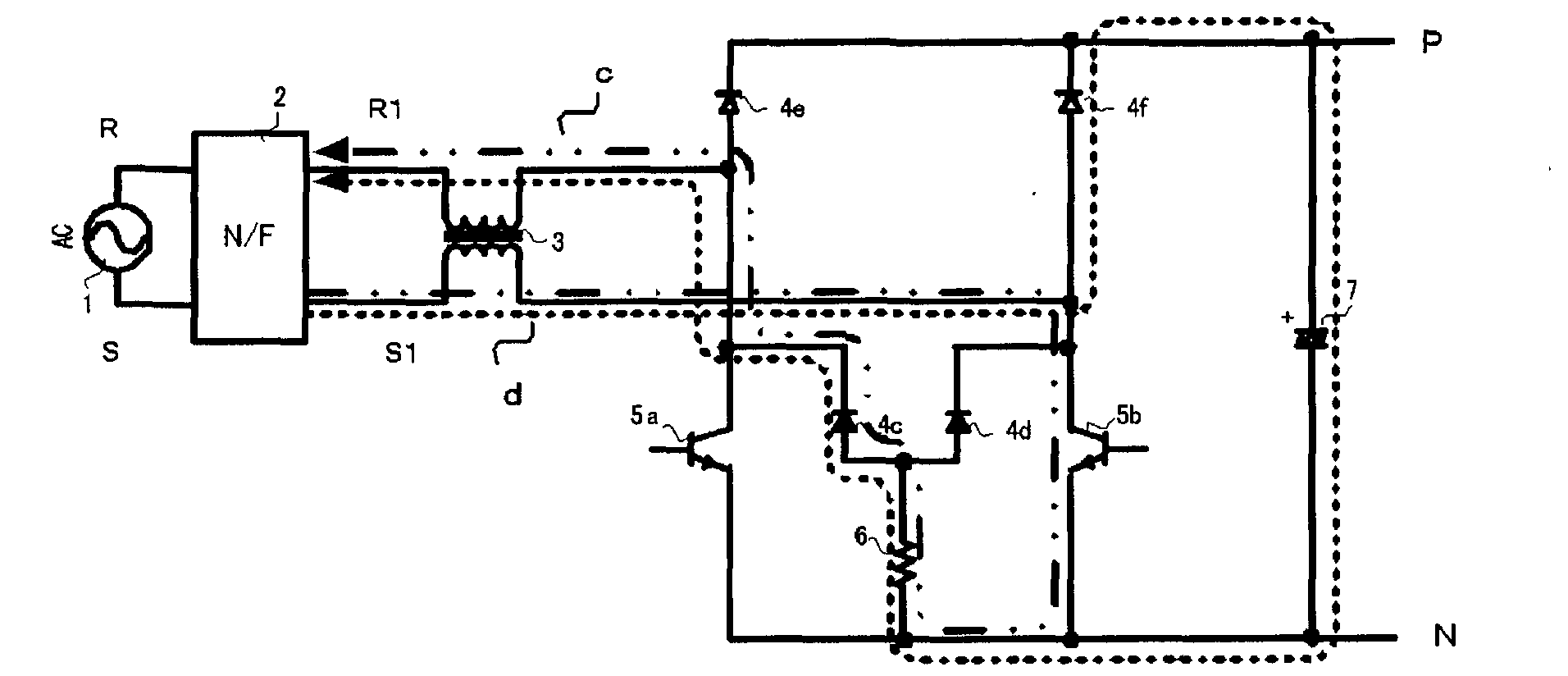

[0025] figure 1 It is a circuit configuration diagram of the half-bridge converter circuit in Embodiment 1 of the present invention, which is used in home appliances such as air conditioners to improve the power factor of the power supply, reduce the harmonic current of the power supply, and control the DC output voltage. Adjusted DC power supply unit. Hereinafter, this circuit will be described as an example. The AC power supply 1 is connected to a rectification circuit 4 via a noise filter 2 and a reactor 3 . The rectifier circuit 4, that is, the diode bridge circuit, is composed of rectifier elements, namely, diodes 4c, 4d, 4e, and 4f. The rectifier elements 4e, 4f are connected to the positive terminal side of the rectifier circuit 4, and the rectifier elements 4c, 4d are connected to the negative terminal side. The shunt resistor 6 for current detection is connected to the negative terminal. Also, semiconductor switching elements 5a, 5b that perform switching operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com